Preparation method of cobalt carbonate and preparation method of cobaltosic oxide

A technology of cobalt tetroxide and cobalt carbonate, applied in the directions of cobalt carbonate, cobalt oxide/cobalt hydroxide, etc., can solve the problems of rising oxalic acid price, rising cost of preparing cobalt tetroxide, and small application range of cobalt tetroxide, achieving high tap density, easy realization and The effect of mastery, low technical starting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

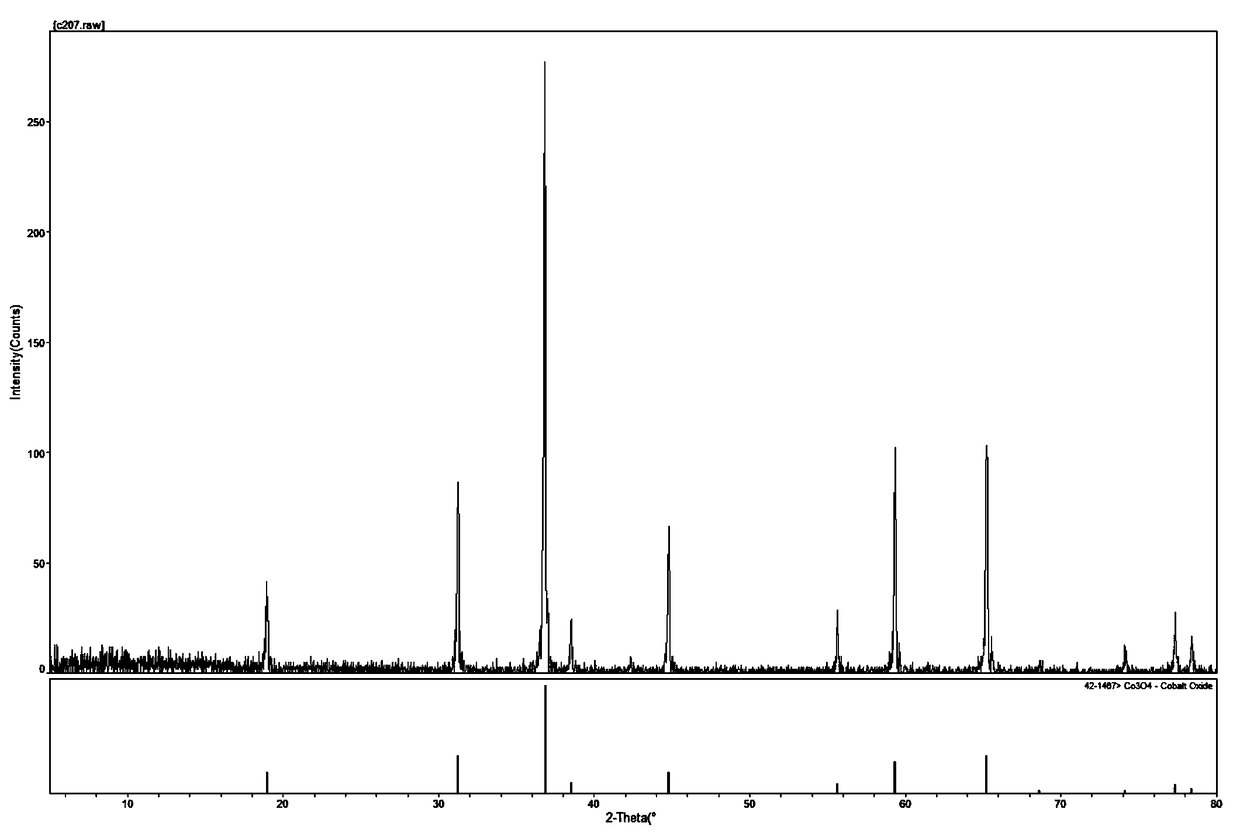

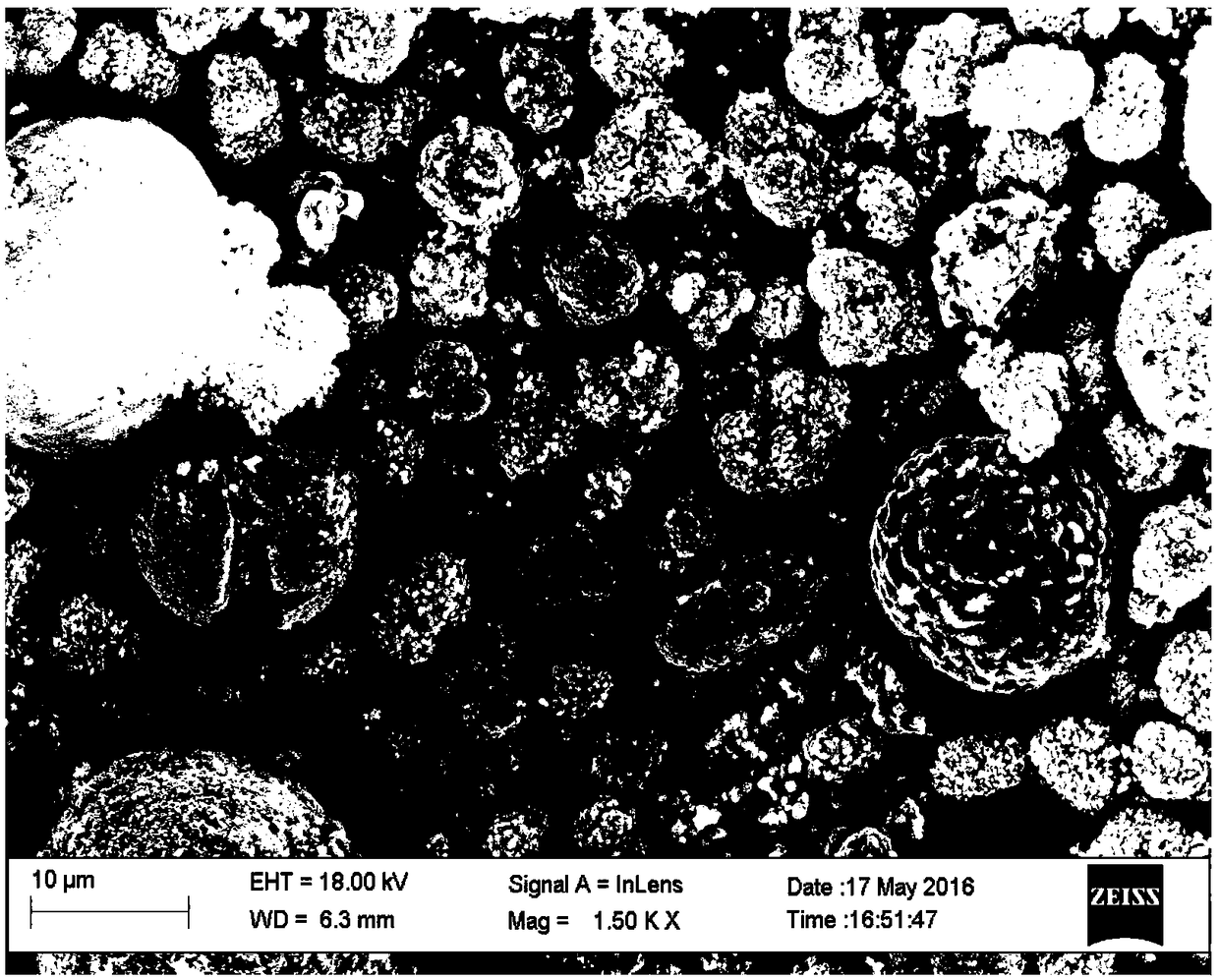

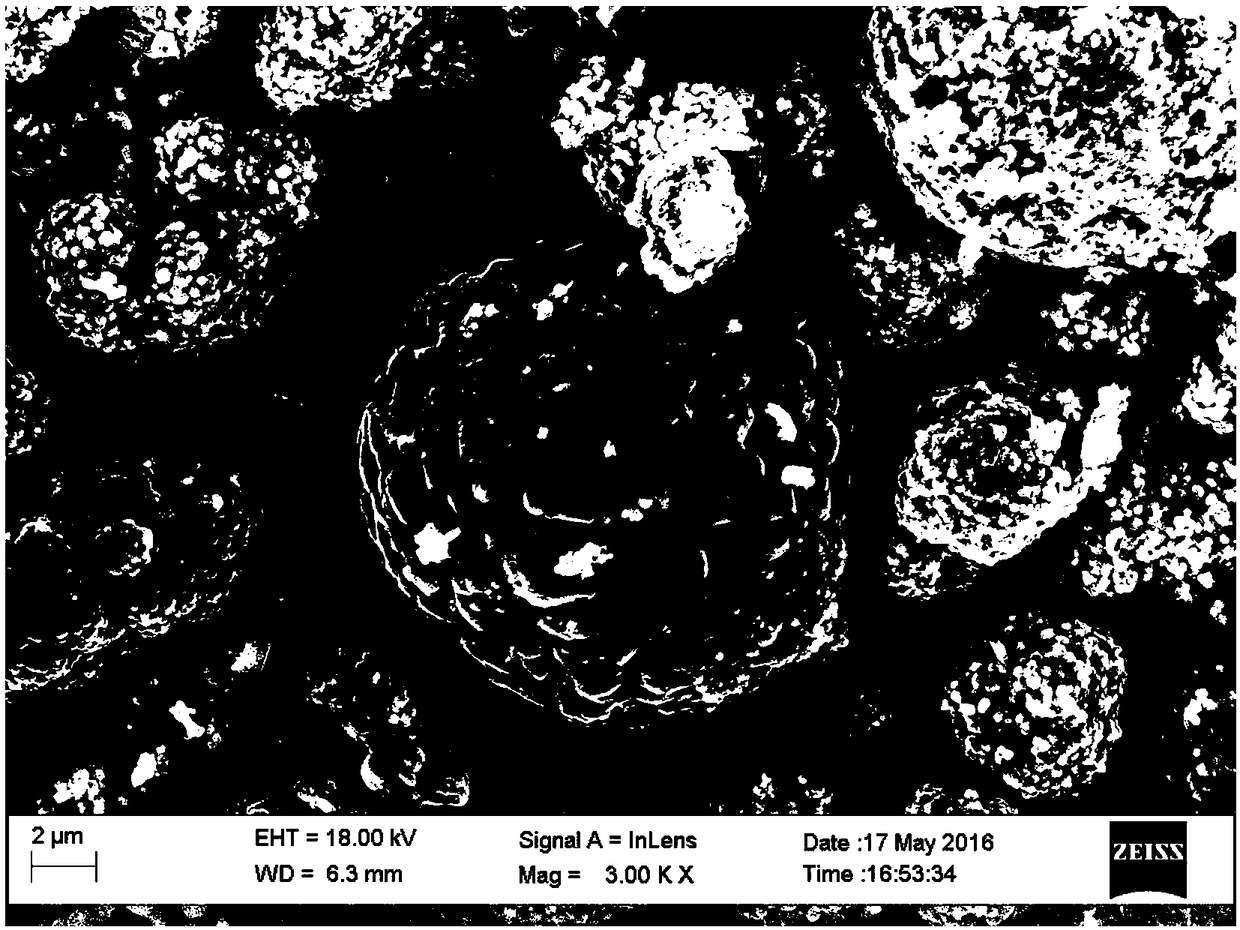

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of tricobalt tetroxide.

[0032] The experimental reagent needed in this embodiment: get ammonium bicarbonate (NH 4 HCO 3 ) and cobalt chloride hexahydrate (CoCl 2 6(H 2 O)). Among them, ammonium bicarbonate is produced by Zhijiang Chemical Co., Ltd., and cobalt chloride hexahydrate is produced by Guangxi Yinyi Co., Ltd.

[0033] The experimental instruments required in this embodiment include: beaker, glass rod, constant temperature water bath, reaction vessel, stirrer, thermometer, lightning magnetic pH meter, muffle furnace, (SHB-3) multi-purpose vacuum pump for circulating water (Suzhou Qile Electronic Technology Co., Ltd. Co., Ltd.) and Malvern2000 laser particle size analyzer (Germany Malvern Instrument Co., Ltd.).

[0034] The preparation method of tricobalt tetroxide comprises the steps:

[0035] Ammonium bicarbonate (NH 4 HCO 3 ), dissolved in pure water, prepared into an ammonium bicarbonate solution with a c...

Embodiment 1

[0049] This embodiment relates to a preparation method of tricobalt tetroxide, which comprises the following steps:

[0050] Take NH 4 HCO 3, dissolved in pure water, prepared into an ammonium bicarbonate solution with a concentration of 240±4g / L, added to the head tank, and set aside.

[0051] Take CoCl 2 6(H 2 0), dissolved in pure water, prepared into a cobalt chloride solution with a concentration of 110 ± 3g / L, added to another elevated tank, and set aside.

[0052] Add a predetermined amount of deionized water into the reaction vessel, and heat the deionized water to 54°C.

[0053] Open the valve of the head tank, add part of the ammonium bicarbonate solution into the reaction vessel, and adjust the pH of the solution in the reaction vessel to a pH of 7.2±0.05.

[0054] The ammonium bicarbonate solution in the head tank and the cobalt chloride solution in the head tank are fed into the reaction vessel by co-current feeding, and the reaction is stirred by a stirrer. ...

Embodiment 2

[0065] This embodiment relates to a preparation method of tricobalt tetroxide, which comprises the following steps:

[0066] Take NH 4 HCO 3 , dissolved in pure water, prepared into an ammonium bicarbonate solution with a concentration of 240±4g / L, added to the head tank, and set aside.

[0067] Take CoCl 2 6(H 2 0), dissolved in pure water, prepared into a cobalt chloride solution with a concentration of 110 ± 3g / L, added to another elevated tank, and set aside.

[0068] Add a predetermined amount of deionized water into the reaction vessel, and heat the deionized water to 57°C.

[0069] Open the valve of the head tank, add part of the ammonium bicarbonate solution into the reaction vessel, and adjust the pH of the solution in the reaction vessel to a pH of 7.5±0.05.

[0070] The ammonium bicarbonate solution in the head tank and the cobalt chloride solution in the head tank were added to the reaction vessel by co-current feeding, and the reaction was stirred by a stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com