Composite opacifier and its preparation method and ceramic glaze and ceramics and application

A technology for compounding emulsion and slurry, applied in the field of ceramics, can solve the problems of poor opacification effect, high radioactivity, expensive raw materials, etc., and achieve the effects of easy control, simple operation, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

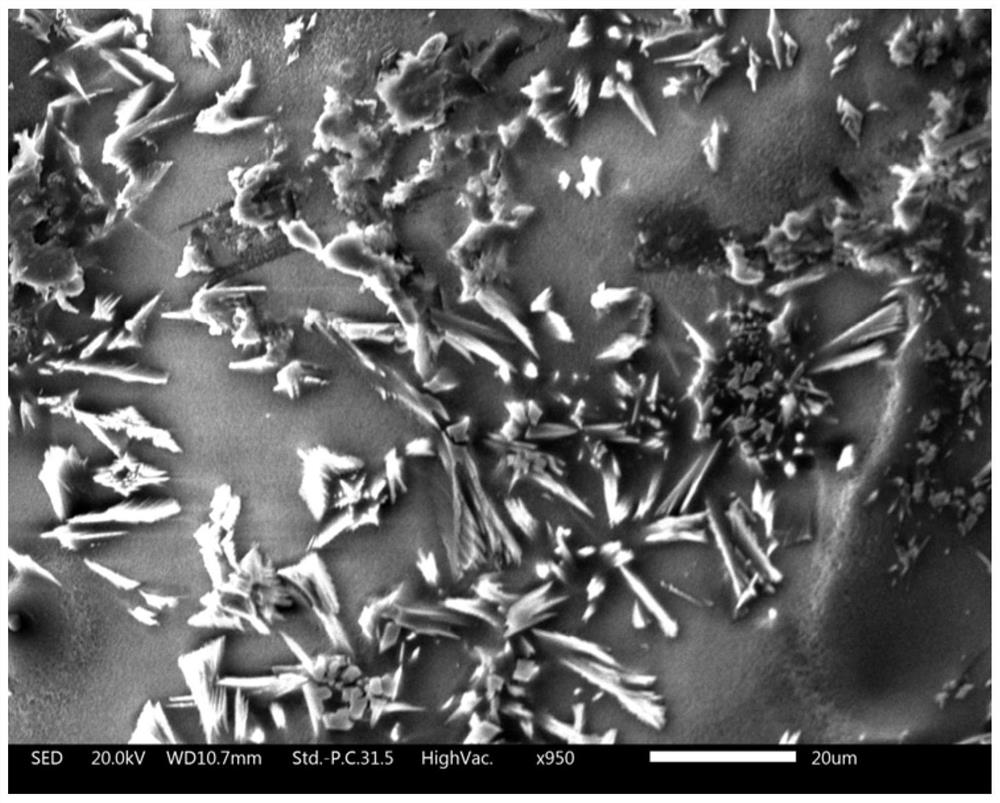

[0077] The preparation method of the composite emulsifying agent provided by the invention is simple, adopts a liquid-phase mechanochemical method, has simple operation, is easy to control, and is suitable for large-scale production.

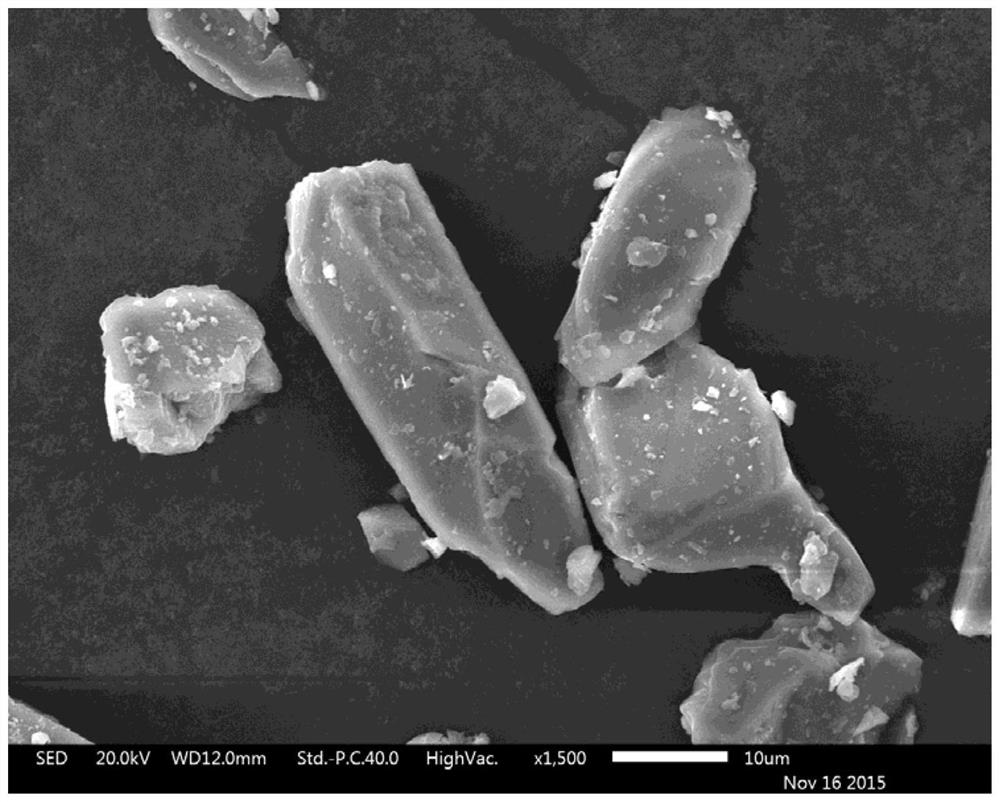

[0078] In a preferred embodiment, in the step (a), the particle size of the apatite in the first slurry is 1.5-2 μm, preferably 1.8 μm.

[0079] If the particle size of apatite is too large, it is not easy to melt, or the second-phase glass droplets formed after melting are not uniformly dispersed, resulting in poor effects of phase separation and crystallization opacification; too small particle size increases the difficulty of production and production costs.

[0080] Wherein, the particle size of apatite may be, for example, but not limited to 1.5 μm, 1.6 μm, 1.7 μm, 1.8 μm, 1.9 μm or 2 μm.

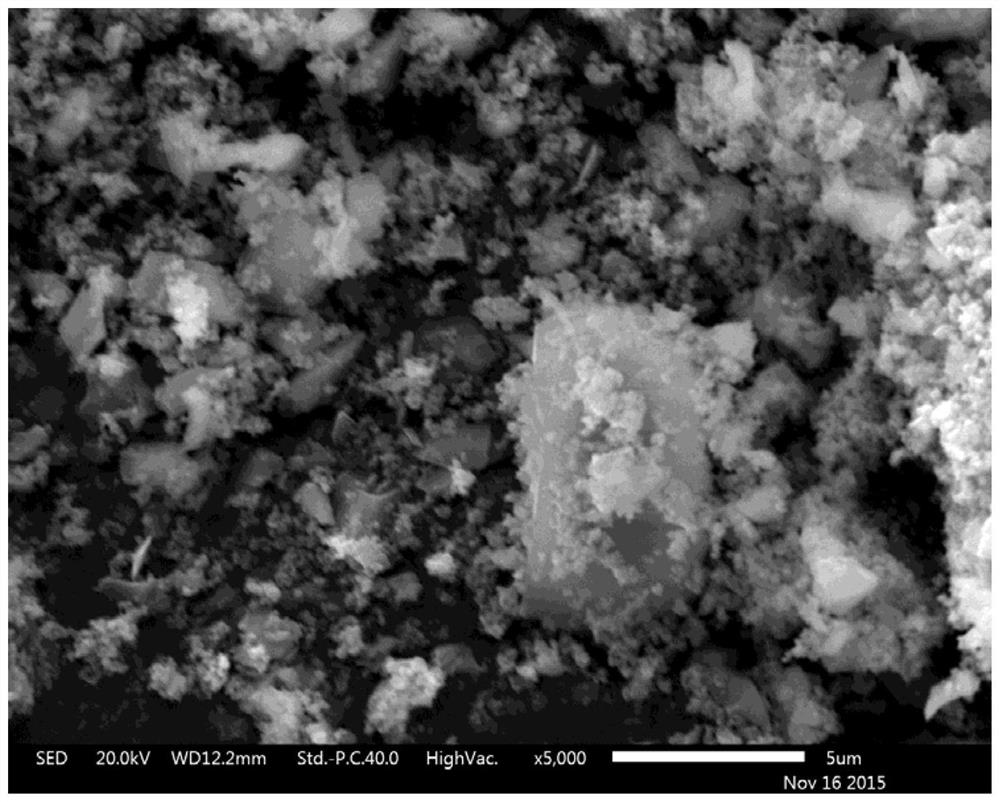

[0081] In a preferred embodiment, the particle size of titanium dioxide, metal oxide and barium salt in the second slurry is 0.1-0.3 μm, preferably 0.2...

Embodiment 1

[0114] This embodiment provides a composite emulsifier, including core-shell microspheres with a core and a coating, the particle size of the core-shell microspheres is 4 μm, the core includes fluoroapatite, and the coating includes anatase Type titanium dioxide;

[0115] The core-shell structure microsphere includes the following components in terms of mass percentage: 45 parts of fluorapatite and 55 parts of anatase titanium dioxide.

Embodiment 2

[0117] This embodiment provides a composite emulsifier, including core-shell microspheres with a core and a coating, the particle size of the core-shell microspheres is 3 μm, the core includes fluoroapatite, and the coating includes anatase Type titanium dioxide;

[0118] The core-shell structure microsphere includes the following components in terms of mass percentage: 42 parts of fluorapatite and 58 parts of anatase titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com