Energy-saving and environment-friendly heat insulation material and preparation method thereof

A thermal insulation material, energy saving and environmental protection technology, applied in the field of thermal insulation materials, can solve the problems of poor compressive and flexural effects, and achieve the effects of improving mechanical properties, high compressive flexural strength, and high flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

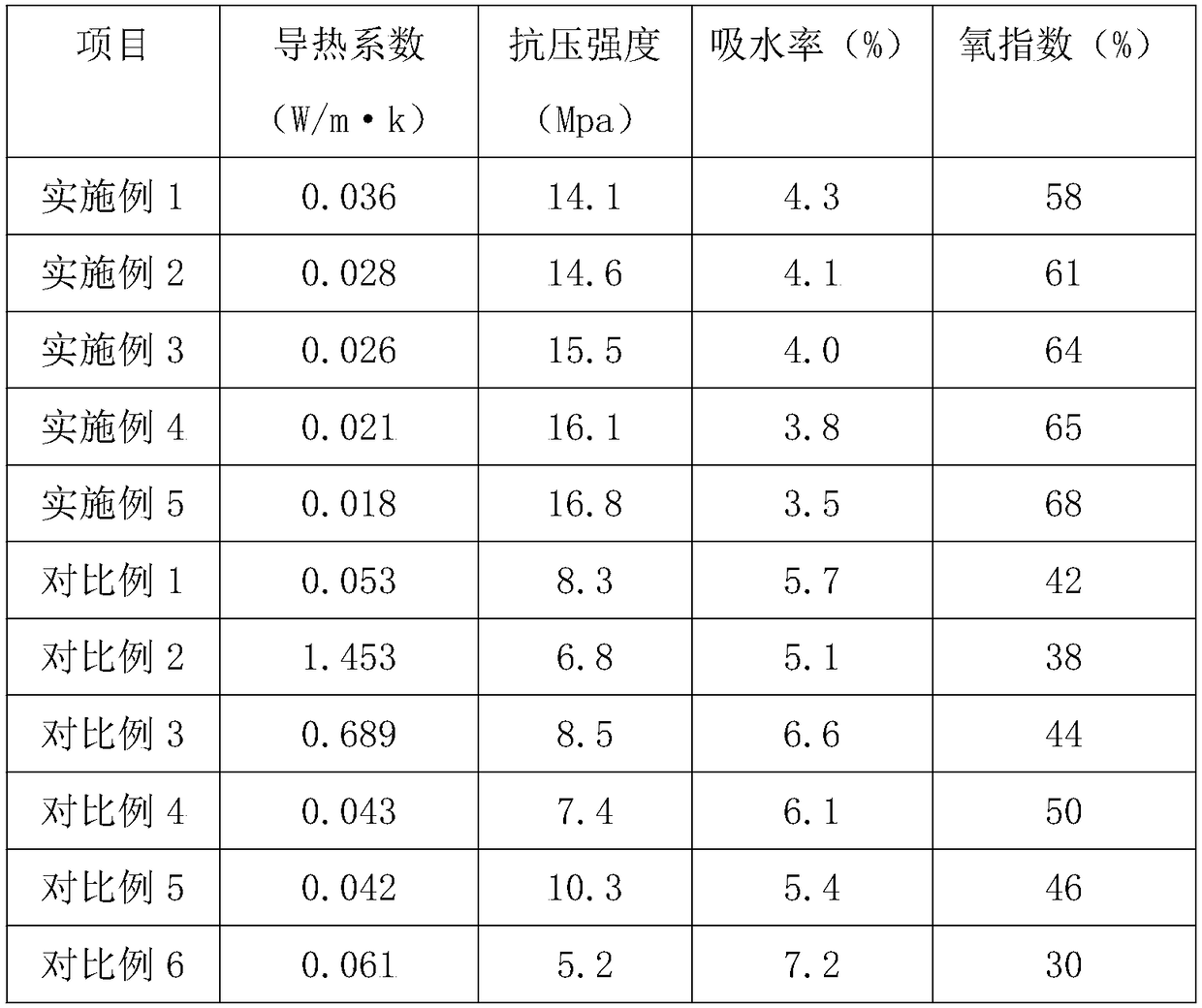

Examples

Embodiment 1

[0029] This embodiment relates to an energy-saving and environment-friendly thermal insulation material, which includes the following raw materials in parts by weight: 20 parts of acrylic milk mortar, 6 parts of polyurethane, 16 parts of porous aluminum phosphate, 8 parts of phosphorus-containing glue, and 6 parts of hollow glass microspheres , 4 parts of barium carbonate, 3 parts of modified polyimide fiber, 5 parts of epoxy-terminated polydimethylsiloxane, 3 parts of nano-zinc borate, and 1 part of compound antioxidant.

[0030] Wherein, the preparation method of the porous aluminum phosphate is: adding a surfactant to the aluminum phosphate, so that the aluminum phosphate is completely submerged, controlling the temperature at 1°C, and then adding 1% acid catalyst and 2% by weight of the surfactant dropwise. Stir well for 10 minutes, let stand for 30 minutes, add propylene oxide after filtration, continue to stir and disperse for 20 minutes, let stand at room temperature for...

Embodiment 2

[0042] This embodiment relates to an energy-saving and environment-friendly thermal insulation material, which includes the following raw materials in parts by weight: 38 parts of acrylic milk mortar, 12 parts of polyurethane, 22 parts of porous aluminum phosphate, 12 parts of phosphorus-containing glue, and 10 parts of hollow glass microspheres , 8 parts of barium carbonate, 7 parts of modified polyimide fiber, 10 parts of epoxy-terminated polydimethylsiloxane, 5 parts of nano-zinc borate, and 2 parts of compound antioxidant.

[0043] Wherein, the preparation method of the porous aluminum phosphate is: adding a surfactant to the aluminum phosphate, so that the aluminum phosphate is completely submerged, controlling the temperature at 4°C, and then adding 3% of the acid catalyst and 4% by weight of the surfactant dropwise. Stir well for 30 minutes, let stand for 40 minutes, add propylene oxide after filtration, continue to stir and disperse for 30 minutes, let stand at room tem...

Embodiment 3

[0055] This embodiment relates to an energy-saving and environment-friendly thermal insulation material, which includes the following raw materials in parts by weight: 22 parts of acrylic milk mortar, 8 parts of polyurethane, 18 parts of porous aluminum phosphate, 9 parts of phosphorus-containing glue, and 7 parts of hollow glass microspheres , 5 parts of barium carbonate, 4 parts of modified polyimide fiber, 7 parts of epoxy-terminated polydimethylsiloxane, 3.5 parts of nano-zinc borate, and 1.2 parts of compound antioxidant.

[0056] Wherein, the preparation method of the porous aluminum phosphate is: adding a surfactant to the aluminum phosphate, so that the aluminum phosphate is completely submerged, controlling the temperature at 1°C, and then adding 1% acid catalyst and 2% by weight of the surfactant dropwise. Stir well for 10 minutes, let stand for 30 minutes, add propylene oxide after filtration, continue to stir and disperse for 20 minutes, let stand at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com