EPDM rubber and its preparation method

A technology of EPDM rubber and polyethylene glycol, which is applied in the field of rubber materials, can solve problems such as poor rubber reinforcement effect, further research on EPDM rubber, and decreased tensile tear strength and rubber elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

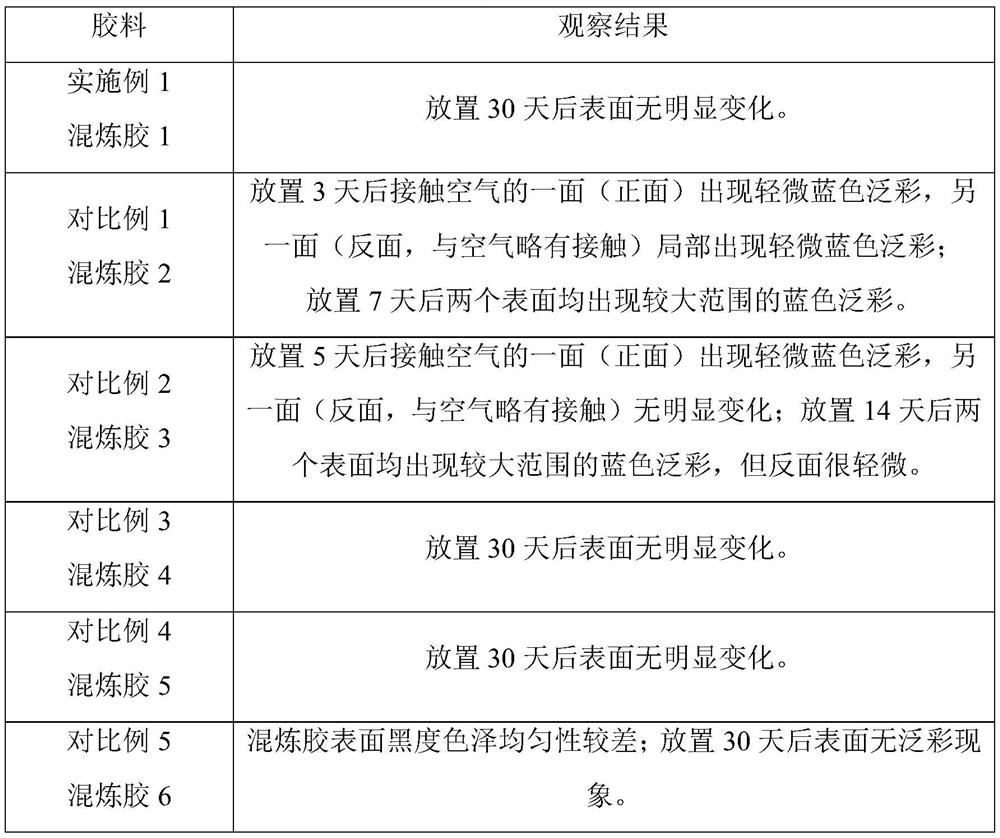

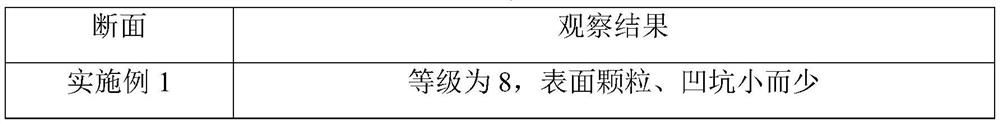

Examples

Embodiment 1

[0035] The raw material formula of EPDM rubber is as follows: 120 parts by weight of EPDM rubber (raw rubber S512F), 70 parts by weight of high-reinforcement carbon black (N330), 70 parts by weight of paraffin oil (KP6030), polyethylene glycol (PEG4000 ) 1 part by weight, 3 parts by weight of microcrystalline wax (L-654), 1 part by weight of antioxidant (2-mercaptobenzimidazole), 1 part by weight of carbon free radical scavenger (HP-136), epoxy 10 parts by weight of resin (E-20), 1 part by weight of stearic acid (SA1801), 6 parts by weight of zinc oxide (active ZnO), 1.2 parts by weight of sulfur, 3.5 parts by weight of accelerator (accelerator CZ (N-cyclohexyl- 2-benzothiazole sulfenamide) 1.3 parts by weight, 1 part by weight of accelerator M (2-thiol benzothiazole), 1 part by weight of accelerator BZ (zinc dibutyldithiocarbamate), 1 part by weight of accelerator TT (tetramethylthiuram disulfide) 0.2 parts by weight).

[0036] The process of preparing EPDM rubber: ① EPDM ru...

Embodiment 2

[0081] The raw material formula of EPDM rubber is as follows: 120 parts by weight of EPDM rubber (raw rubber S512F), 50 parts by weight of high-reinforcement carbon black (N550), 50 parts by weight of paraffin oil (KP6030), polyethylene glycol (PEG4000 ) 0.5 parts by weight, microcrystalline wax (L-654) 1 parts by weight, antioxidant (2-thiol benzimidazole) 0.8 parts by weight, carbon free radical scavenger (HP-136) 0.2 parts by weight, epoxy 2 parts by weight of resin (E-20), 1.5 parts by weight of stearic acid (SA1801), 4 parts by weight of zinc oxide (active ZnO), 1 part by weight of sulfur, 2 parts by weight of accelerator (accelerator CZ (N-cyclohexyl- 2-benzothiazole sulfenamide) 1 part by weight, accelerator M (2-thiol benzothiazole) 0.5 parts by weight, accelerator BZ (zinc dibutyldithiocarbamate) 0.4 parts by weight, accelerator TT (tetramethylthiuram disulfide) 0.1 parts by weight).

[0082] The preparation method is the same as in Example 1.

[0083] Experimental ...

Embodiment 3

[0085] The raw material formula of EPDM rubber is as follows: 120 parts by weight of EPDM rubber (raw rubber S512F), 80 parts by weight of high-reinforcement carbon black (N330), 80 parts by weight of paraffin oil (KP6030), polyethylene glycol (PEG4000 ) 0.8 parts by weight, microcrystalline wax (L-654) 1.8 parts by weight, antioxidant (2-thiol benzimidazole) 0.8 parts by weight, carbon free radical scavenger (HP-136) 0.7 parts by weight, epoxy 7 parts by weight of resin (E-20), 2 parts by weight of stearic acid (SA1801), 8 parts by weight of zinc oxide (active ZnO), 1.5 parts by weight of sulfur, 4 parts by weight of accelerator (accelerator CZ (N-cyclohexyl- 2-benzothiazole sulfenamide) 1.5 parts by weight, accelerator M (2-thiol benzothiazole) 1.1 parts by weight, accelerator BZ (zinc dibutyldithiocarbamate) 1.1 parts by weight, accelerator TT (tetramethylthiuram disulfide) 0.3 parts by weight).

[0086] The preparation method is the same as in Example 1.

[0087] Experim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com