Method for preventing runt seedlings in root extending period of ridged mulching film tobaccos

A technology of mulching film and ridge planting, which is applied in the fields of botanical equipment and methods, tobacco cultivation, plant protection cover, etc., can solve the problems of high humidity in the cellar space, many agricultural operations, insufficient dissolution and fermentation of chemical fertilizers, etc. Covering negative effects, beneficial to nutrient coupling efficiency, and the effect of improving ventilation and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

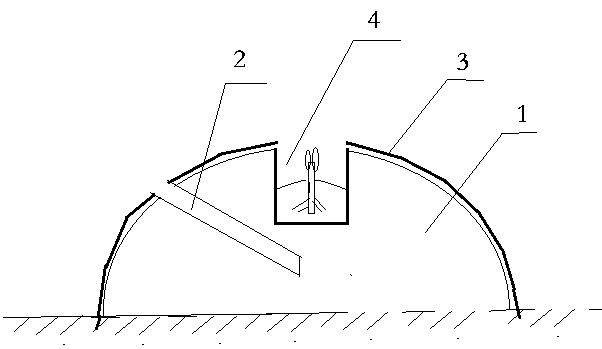

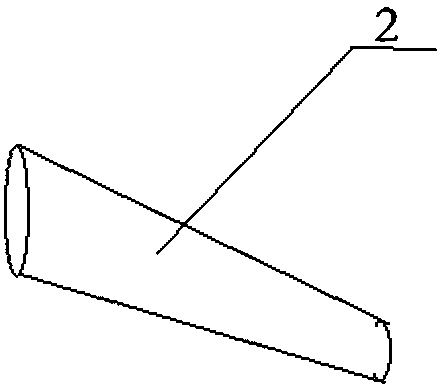

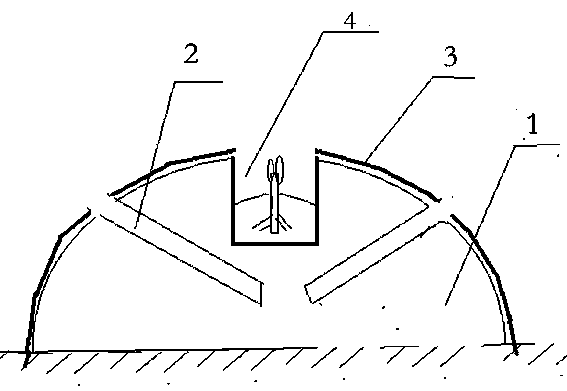

[0035] Ridge 1 in the tobacco field, such as figure 1 The height of the middle ridge 1 is 25-30 cm, the width of the top of the ridge surface is 50-60 cm, and the length of the ridge is determined according to the field drainage and planting habits. Cover the surface with a film 3, and punch a vertical planting hole 4 on the curved surface of the ridge top. Preferably, the depth of the vertical planting hole 4 is 10-15 cm, and the tobacco seedlings are put into the vertical planting hole 4, a kind of ridge planting film The method of preventing stiff seedlings at the rooting stage of tobacco includes moving the tobacco seedlings in the vertical planting hole 4 for 5-10 days, and then choosing a sunny day to drill inclined holes 2 on one side or two sides of the ridge 1. The first inclined hole or the second inclined hole can be determined according to the weather conditions. Generally speaking, the oblique hole 2 on one side is drilled first. If the humidity of ridge 1 is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com