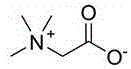

A kind of improved betaine surfactant system with block copolymer and use thereof

A technology of surfactants and block copolymers, which is applied in the field of chemical flooding systems (ie, chemical flooding systems, chemical flooding additives), can solve the problems of negative impacts on oil production and the environment, formation damage, and limited improvement in oil production capacity. Achieve the significance of protecting natural resources, strong anti-salinity ability, and improve oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 50% betaine surfactant single agent solution: take oleyl dimethyl betaine (from Western Surfactants Research and Development Center, USA, with 30% activity (i.e. effective concentration), pH6.0-7.0) 50 grams of deionized water, 50 grams of deionized water; add to a beaker respectively, and then stir evenly at room temperature with a magnetic stirrer. Adjust the pH to 7-8 with sodium hydroxide and acetic acid. The formed surfactant system is a homogeneous transparent liquid.

[0036] Crude oil: from oil fields in Northeast China, the crude oil presents high acidity and high aromatic components.

[0037] Test instrument: TX-500C interfacial tension.

[0038] Test conditions: (1) temperature 55 degrees Celsius; (2) reinjection water containing salinity of 4000mg / L; (3) polymer: 1000ppm polyacrylamide (from Liaoning Panjin Heilan Chemical Co., Ltd. with a molecular weight of 25 million); (4) surface activity Agent concentration: 0.05% and 0.10%. This surfactant concentr...

Embodiment 2

[0042] In the surfactant of Example 1 above, a polyoxyethylene polypropylene oxide block copolymer, represented by T1, was added. The general structural formula of T1 is as follows (A or B):

[0043] A.: (EO) n –(PO) m – (EO) p ;or

[0044] B.: (PO) n – (EO) m –(PO) p

[0045] Among them, EO stands for ethylene oxide, PO stands for propylene oxide; m, n, p are the repetition times of the monomer, and the value range of m, n, p is 0-400.

[0046] T1 is formed by staged polymerization. First, the monomer reacts to produce the middle part (for example, first propylene oxide is polymerized; then another monomer (such as ethylene oxide) is used to continue the polymerization reaction to complete the parts at both ends.

[0047] The specific configuration is as follows: take 50 grams of oleyl dimethyl betaine (same as Example 1), T1 (polyethylene oxide polypropylene oxide block copolymer, from Panjin Hailan Chemical Industry, Liaoning, with a molecular weight of 2000 -2500D...

Embodiment 3

[0054] Surfactant preparation: get oleylamide dimethyl propyl betaine (from U.S. Western Surfactants Research and Development Center (WesternSurfactantsResearchandDevelopmentCenter, USA, have 35% activity, pH6.0-7.0) 50 grams, deionized water 50 grams Add the above to a beaker respectively, and then stir evenly at room temperature with an electromagnetic stirrer. Regulate the pH to 7-8 with sodium hydroxide and acetic acid. The formed surfactant system is a uniform transparent liquid.

[0055] Crude oil: with embodiment 1.

[0056] Test instrument: TX-500C interfacial tension.

[0057] Test conditions: (1) temperature 55 degrees Celsius; (2) reinjection water containing salinity 4000mg / L;

[0058] (3) Polymer: 1000ppm polyacrylamide (from Liaoning Panjin Heilan Chemical Co., Ltd. with a molecular weight of 25 million); (4) Surfactant concentration: 0.2%.

[0059] Test results: When the surfactant concentration is 0.2%, the oil-water interfacial tension is 0.11dyn / cm.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com