A kind of preparation method of flexible organic piezoelectric-photocatalytic composite helical fiber

A photocatalytic and photocatalytic technology, applied in the field of composite helical fibers, can solve the problems of easy saturation of the built-in electric field of the catalyst, low photocatalytic efficiency, etc., and achieve the effect of good catalytic effect, promotion of effective separation, and realization of self-healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Flexible organic piezoelectric-photocatalytic composite helical fiber PVDF / g-C 3 N 4 preparation of

[0025] S1: Add 0.2 g of pre-synthesized photocatalyst powder g-C to 9.0 g of solvent DMF 3 N 4 Ultrasonic dispersion is performed to form a photocatalyst dispersion liquid.

[0026] g-C 3 N 4 Prepared by the following steps:

[0027] S1.1 Weigh a certain amount of urea in a mortar, grind it thoroughly and transfer it to a corundum crucible;

[0028] S1.2 Put the corundum crucible into the muffle furnace for sintering, and put the reactants at 25 o C / min increased to 520 o C, keep warm for 2 hours;

[0029] S1.3 Cool the muffle furnace and the internal product to room temperature at 25°C / min to obtain a light yellow powder;

[0030] S1.4 Weigh a certain amount of light yellow powder and spread it in the corundum ark;

[0031] S1.5 Transfer the corundum ark containing the light yellow powder to the muffle furnace, sinter the powder again, and the heating rate i...

Embodiment 2

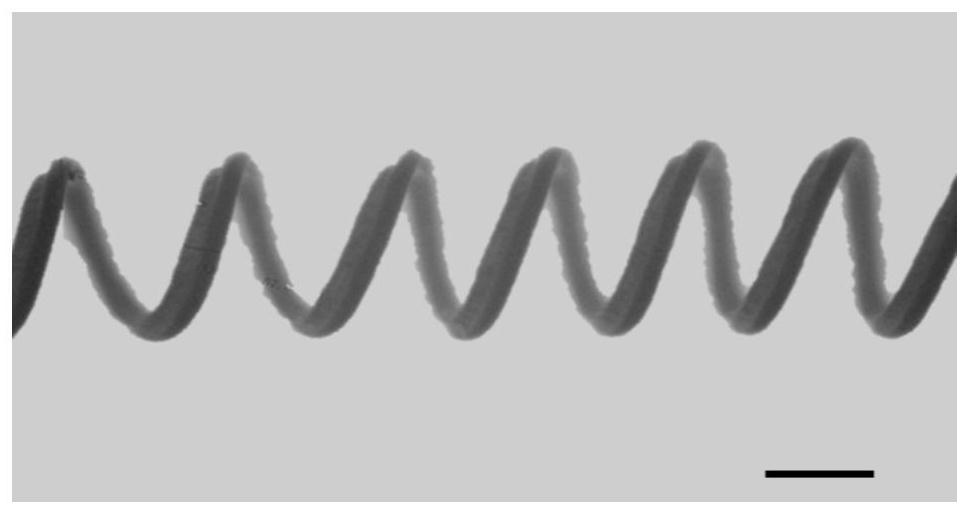

[0042] The diameter of the outlet pipe of the microfluidic device in Example 1 was set to 100 μm, and the flow rate was set to 6 mL / s. In the same manner as in Example 1, helical fibers were prepared.

[0043]The obtained composite helical fiber has a uniform size, the helical diameter of the fiber is about 1.1 mm, the pitch is about 3.0 mm, and the diameter of the fiber is about 0.15 mm.

Embodiment 3

[0045] The diameter of the outlet pipe of the microfluidic device in Example 1 was set to 180 μm, and the flow rate was set to 30 mL / s. In the same manner as in Example 1, helical fibers were prepared.

[0046] The obtained composite helical fiber is uniform in size, the helical diameter of the fiber is 2.6 mm, the pitch is 0.78 mm, and the diameter of the fiber is about 0.35 mm.

[0047] Organic piezoelectric-photocatalytic composite helical fiber PVDF / g-C 3 N 4 Catalytic Degradation of Organic Pollutant Rhodamine B

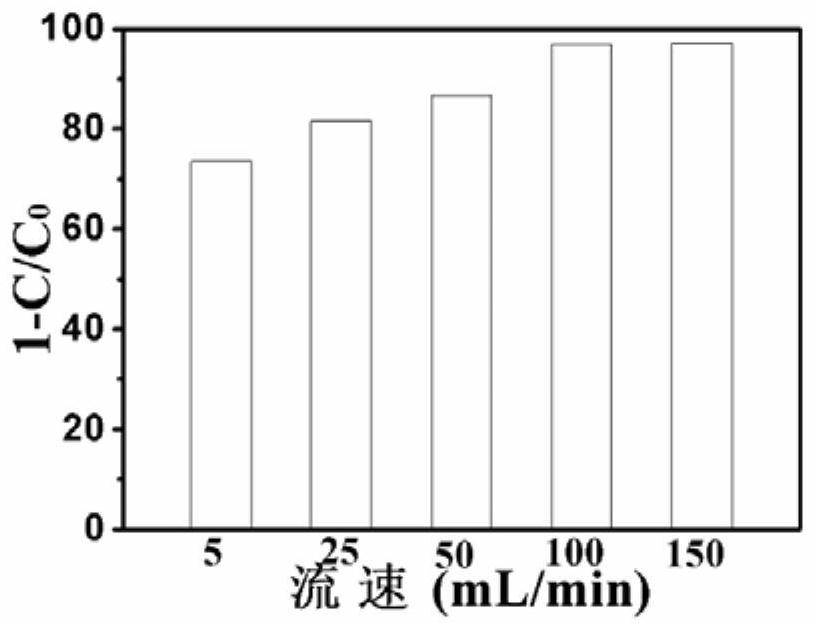

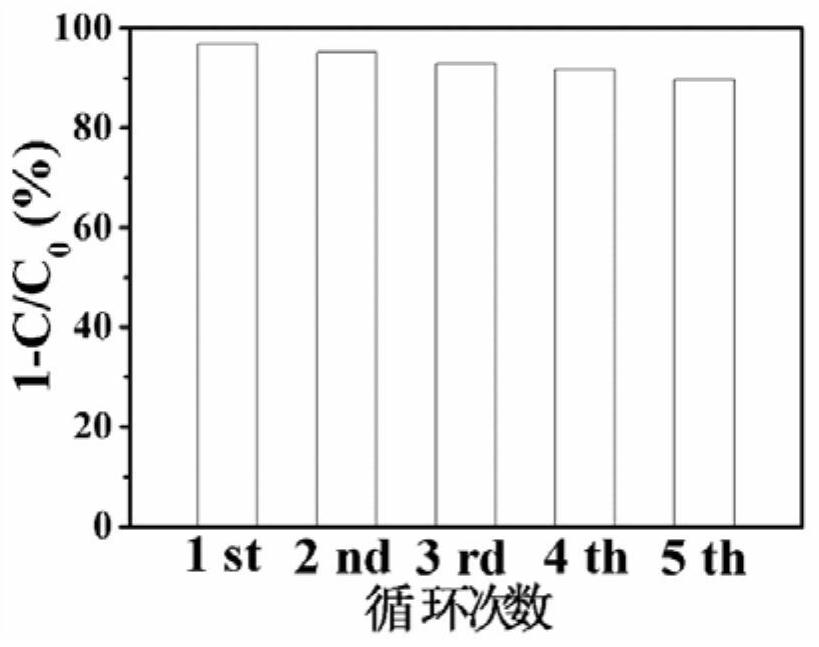

[0048] First, the spiral micron composite fiber prepared in Example 1 is packed into a quartz capillary with a diameter of 2 mm and a length of 5 cm. The two ends of the capillary are aligned, encapsulated with a quartz glass sheet, and connected with a syringe to prepare a photocatalytic microreactor. . Each reactor contains 15 quartz capillary tubes equipped with helical fibers to ensure a certain amount of photocatalyst. Subsequently, 0.012 g of rhodamine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com