Preparation method of layered cement and mswi bottom ash alkali-activated double gelling system material

A technology of alkali excitation and cement glue, which is applied in the direction of cement production, etc., can solve the problems of incompatibility between cement and MSWI bottom ash alkali excitation materials, and the inability to develop cement and MSWI bottom ash alkali excitation materials, etc., to achieve significant environmental benefits and social benefits. benefits, slowing down excessive consumption, and eliminating compatibility issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method includes: MSWI bottom ash crushing process, grinding process, weighing and batching and mixing process, and the preparation and pouring process of double-gel system materials. The specific methods are as follows:

[0030] (1) Crushing process: MSWI bottom ash is the product of municipal solid waste incineration, and the MSWI bottom ash micropowder used in the double gelling system material has been dried and crushed. That is, the MSWI bottom ash raw material is continuously dried at 60°C for 2 hours, and then crushed into particles with a diameter of 0<d≤5mm by a crusher.

[0031] (2) Grinding process: The crushed MSWI bottom ash particles can be used as a cementitious material after being ground by a ball mill for 0.5 hours (the specific surface area reaches 400 m 2 / kg, MSWI bottom ash particles with a particle size of less than 30 μm account for more than 90% of the total mass);

[0032] Blast furnace granulated slag powder is S95 grade, with ...

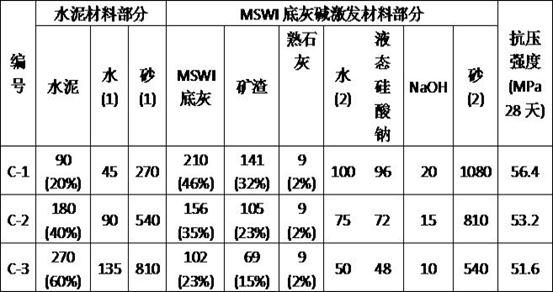

Embodiment 1

[0037] Embodiment 1: the preparation method of layered cement and MSWI bottom ash alkali-activated double gelling system material, raw material composition and mass percentage thereof are as follows: cement cementitious material accounts for 20% of gel total amount (dosage 117.2kg / m 3 ), the MSWI bottom ash alkali-activated material accounts for 80% of the total gel (amount of 468.7kg / m 3 ). Wherein the alkali-activated gelling material is ground MSWI bottom ash 58% (dosage 273.4kg / m 3 ); ground blast furnace granulated slag 32% (dosage 183.6kg / m 3 ); ground slaked lime powder 2% (dosage 11.7kg / m 3 ); the fine aggregate is medium-coarse sand (amount of 1757.7kg / m 3 ); liquid water glass with a modulus of 2.75 (dosage 125kg / m 3 ); caustic soda (NaOH dosage 26kg / m 3 ); water (amount 188.8kg / m 3 );

Embodiment 2

[0038] Embodiment 2: the preparation method of layered cement and MSWI bottom ash alkali-activated double gelling system material, raw material composition and mass percentage thereof are as follows: cement cementitious material accounts for 40% of gel total amount (dosage 234.4kg / m 3 ), the MSWI bottom ash alkali excitation material accounts for 60% of the total amount of the gel (amount of 351.5kg / m 3 ). Wherein the alkali-activated gelling material is ground MSWI bottom ash 35% (dosage 203.1kg / m 3 ); ground blast furnace granulated slag 23% (dosage 136.7kg / m 3 ); ground slaked lime powder 2% (dosage 11.7kg / m 3 ); the fine aggregate is medium and coarse sand (1757.7kg / m 3 ); liquid water glass with a modulus of 2.75 (amount of 93.7kg / m 3 ); caustic soda (NaOH dosage 19.5kg / m 3 ); water (dosage 214.8kg / m 3 );

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com