A kind of high-strength flame-retardant polycarbonate composite material and its preparation method

A technology of flame retardant polycarbonate and composite materials, applied in the field of flame retardant polymer materials, can solve problems such as poor performance, and achieve the effect of improving flame retardant performance and bending strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

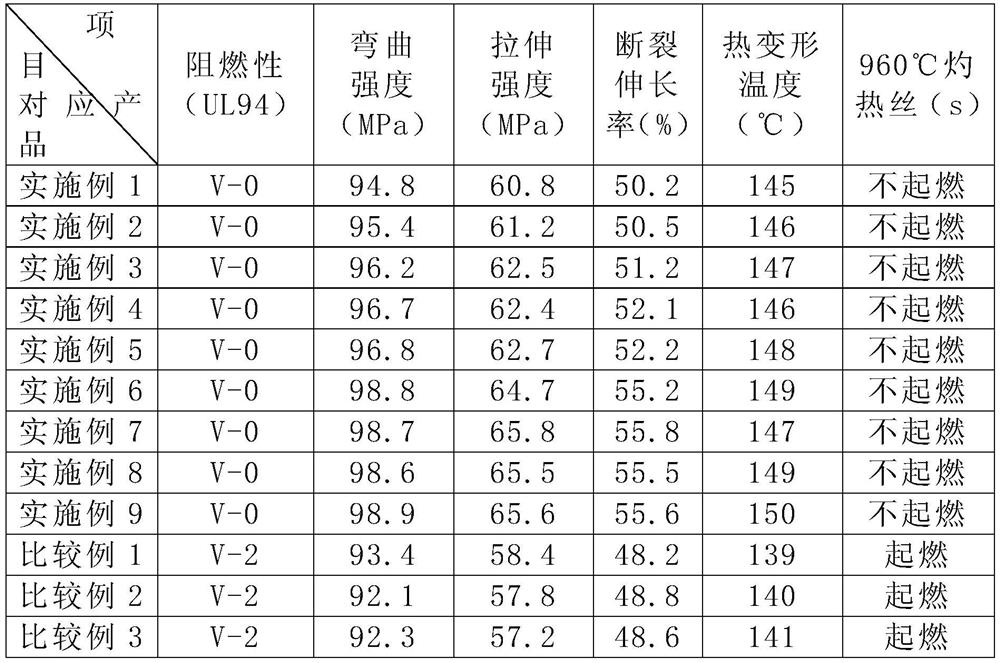

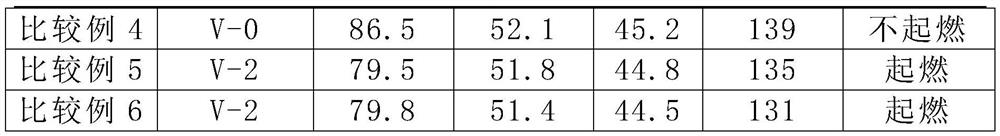

Examples

Embodiment 1

[0025] The polycarbonate composite material in the present embodiment comprises the parts by weight of following composition:

[0026] Polycarbonate: 90; Polyisobutylene: 1.0; Phosphorous halogen-free flame retardant triphenyl phosphate: 2.0; 9,10-dihydro-10-hydroxy-9-oxa-10-phosphaphenanthrene-10- Thione guanidine salt: 4.0; Phosphorus-containing imide ester: 0.5; Nanoscale hydrotalcite powder: 2.0, the particle size of the hydrotalcite powder is 100nm; Condensed polycyclic polynuclear aromatic hydrocarbon resin: 10; Perfluorooctane sulfonate Sodium acid: 2.0; Kaolin: 0.7; Anti-dripping agent perfluorinated polyolefin: 10; Glass fiber: 4.0; Styrene-ethylene / butylene-styrene block copolymer (SEBS); 3.0; Butylene Succinate: 5.0; Antioxidant 1010: 1.0.

[0027] Above-mentioned polycarbonate composite material can adopt following method to prepare:

[0028] Weigh the corresponding weight ratio according to the weight ratio of the above raw materials, first pre-dry the polycarbo...

Embodiment 2

[0030] The polycarbonate composite material in the present embodiment comprises the parts by weight of following composition:

[0031] Polycarbonate: 50, the viscosity-average molecular weight of polycarbonate is 16000; polyisobutylene: 1.5; phosphorus-based halogen-free flame retardant polyphosphate: 5.0; 9,10-dihydro-10-hydroxy-9-oxa- 10-phosphaphenanthrene-10-thione guanidine salt: 4.0; phosphorus-containing imide ester: 0.8; nanoscale hydrotalcite powder: 3.0, the particle size of the hydrotalcite powder is 200nm; condensed polycyclic polynuclear aromatic hydrocarbon resin : 15; sodium perfluorooctane sulfonate: 1.0; kaolin: 0.5; anti-dripping agent polytetrafluoroethylene: 5.0; glass fiber: 2.0; styrene-ethylene / butylene-styrene block copolymer (SEBS) : 5.0; Ethylene-vinyl acetate copolymer: 8.0; Antioxidant 168: 1.5.

[0032] Above-mentioned polycarbonate composite material can adopt following method to prepare:

[0033] Weigh the corresponding weight ratio according t...

Embodiment 3

[0037] The polycarbonate composite material in the present embodiment comprises the parts by weight of following composition:

[0038] Aromatic polycarbonate: 70, and the viscosity average molecular weight of aromatic polycarbonate is 28000; Polyisobutylene: 1.2; Pyrophosphate: 2.0; 9,10-dihydro-10-hydroxy-9-oxa-10- Phosphaphenanthrene-10-thione guanidine salt: 3.0; pentaerythritol diphosphate melamine salt: 1.0; phosphorus imide ester: 0.7; nanoscale hydrotalcite powder: 2.5, the particle size of the hydrotalcite powder is 300nm; Condensed polycyclic polynuclear aromatic hydrocarbon resin: 12; Sodium perfluorooctane sulfonate: 1.5; Kaolin: 0.6; Anti-dripping agent PTFE: 2.0; Glass fiber: 3.0; Glycidyl ester copolymer: 5.0; Ethylene-vinyl acetate copolymer: 8.0; Antioxidant 1076: 1.5; The above-mentioned phosphorus-containing horse imide ester, nanoscale hydrotalcite powder and condensed polycyclic polynuclear aromatic hydrocarbon resin are mixed in advance Particle treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com