High-strength and flame-retardant polycarbonate composite and preparation method thereof

A technology of flame-retardant polycarbonate and composite materials, which is applied in the field of flame-retardant polymer materials, can solve problems such as poor performance, achieve high temperature resistance, improve flame-retardant performance, and achieve good synergistic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

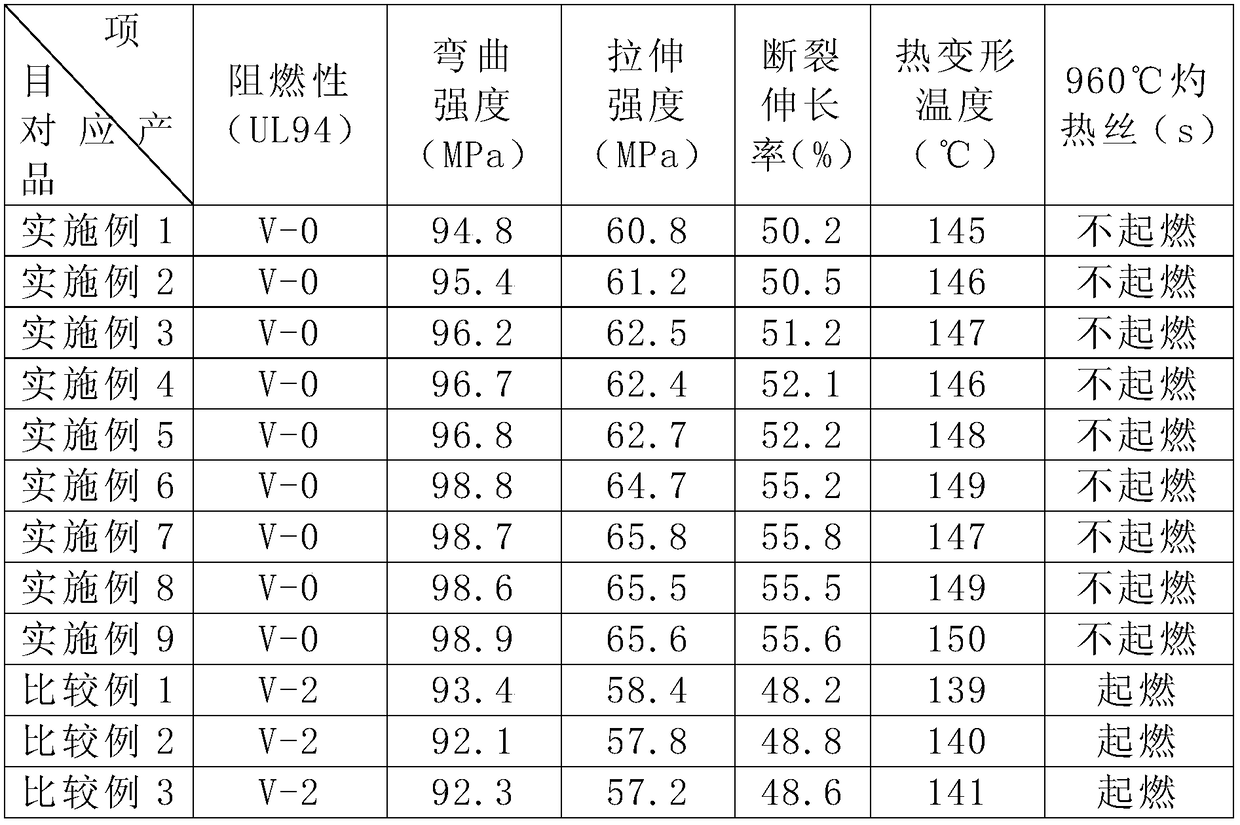

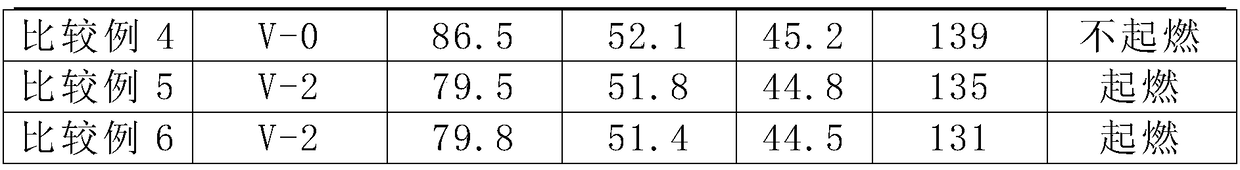

Examples

Embodiment 1

[0025] The polycarbonate composite material in the present embodiment comprises the parts by weight of following composition:

[0026] Polycarbonate: 90; Polyisobutylene: 1.0; Phosphorous halogen-free flame retardant triphenyl phosphate: 2.0; 9,10-dihydro-10-hydroxy-9-oxa-10-phosphaphenanthrene-10- Thione guanidine salt: 4.0; Phosphorus-containing imide ester: 0.5; Nanoscale hydrotalcite powder: 2.0, the particle size of the hydrotalcite powder is 100nm; Condensed polycyclic polynuclear aromatic hydrocarbon resin: 10; Perfluorooctane sulfonate Sodium acid: 2.0; Kaolin: 0.7; Anti-dripping agent perfluorinated polyolefin: 10; Glass fiber: 4.0; Styrene-ethylene / butylene-styrene block copolymer (SEBS); 3.0; Butylene Succinate: 5.0; Antioxidant 1010: 1.0.

[0027] Above-mentioned polycarbonate composite material can adopt following method to prepare:

[0028] Weigh the corresponding weight ratio according to the weight ratio of the above raw materials, first pre-dry the polycarbo...

Embodiment 2

[0030] The polycarbonate composite material in the present embodiment comprises the parts by weight of following composition:

[0031] Polycarbonate: 50, the viscosity-average molecular weight of polycarbonate is 16000; polyisobutylene: 1.5; phosphorus-based halogen-free flame retardant polyphosphate: 5.0; 9,10-dihydro-10-hydroxy-9-oxa- 10-phosphaphenanthrene-10-thione guanidine salt: 4.0; phosphorus-containing imide ester: 0.8; nanoscale hydrotalcite powder: 3.0, the particle size of the hydrotalcite powder is 200nm; condensed polycyclic polynuclear aromatic hydrocarbon resin : 15; sodium perfluorooctane sulfonate: 1.0; kaolin: 0.5; anti-dripping agent polytetrafluoroethylene: 5.0; glass fiber: 2.0; styrene-ethylene / butylene-styrene block copolymer (SEBS) : 5.0; Ethylene-vinyl acetate copolymer: 8.0; Antioxidant 168: 1.5.

[0032] Above-mentioned polycarbonate composite material can adopt following method to prepare:

[0033] Weigh the corresponding weight ratio according t...

Embodiment 3

[0037] The polycarbonate composite material in the present embodiment comprises the parts by weight of following composition:

[0038] Aromatic polycarbonate: 70, and the viscosity average molecular weight of aromatic polycarbonate is 28000; Polyisobutylene: 1.2; Pyrophosphate: 2.0; 9,10-dihydro-10-hydroxy-9-oxa-10- Phosphaphenanthrene-10-thione guanidine salt: 3.0; pentaerythritol diphosphate melamine salt: 1.0; phosphorus imide ester: 0.7; nanoscale hydrotalcite powder: 2.5, the particle size of the hydrotalcite powder is 300nm; Condensed polycyclic polynuclear aromatic hydrocarbon resin: 12; Sodium perfluorooctane sulfonate: 1.5; Kaolin: 0.6; Anti-dripping agent PTFE: 2.0; Glass fiber: 3.0; Glycidyl ester copolymer: 5.0; Ethylene-vinyl acetate copolymer: 8.0; Antioxidant 1076: 1.5; The above-mentioned phosphorus-containing horse imide ester, nanoscale hydrotalcite powder and condensed polycyclic polynuclear aromatic hydrocarbon resin are mixed in advance Particle treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com