Fluorine-containing nano-sio with photoinitiating activity 2 The preparation method of microsphere and nanometer sio 2

A technology of photoinitiation and photoinitiator, which is applied in the direction of dyeing low molecular organic compound treatment, coating, fibrous filler, etc. It can solve the problems of oxygen inhibition and coating surface properties to be improved, so as to improve stability and gloss Good degree, good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

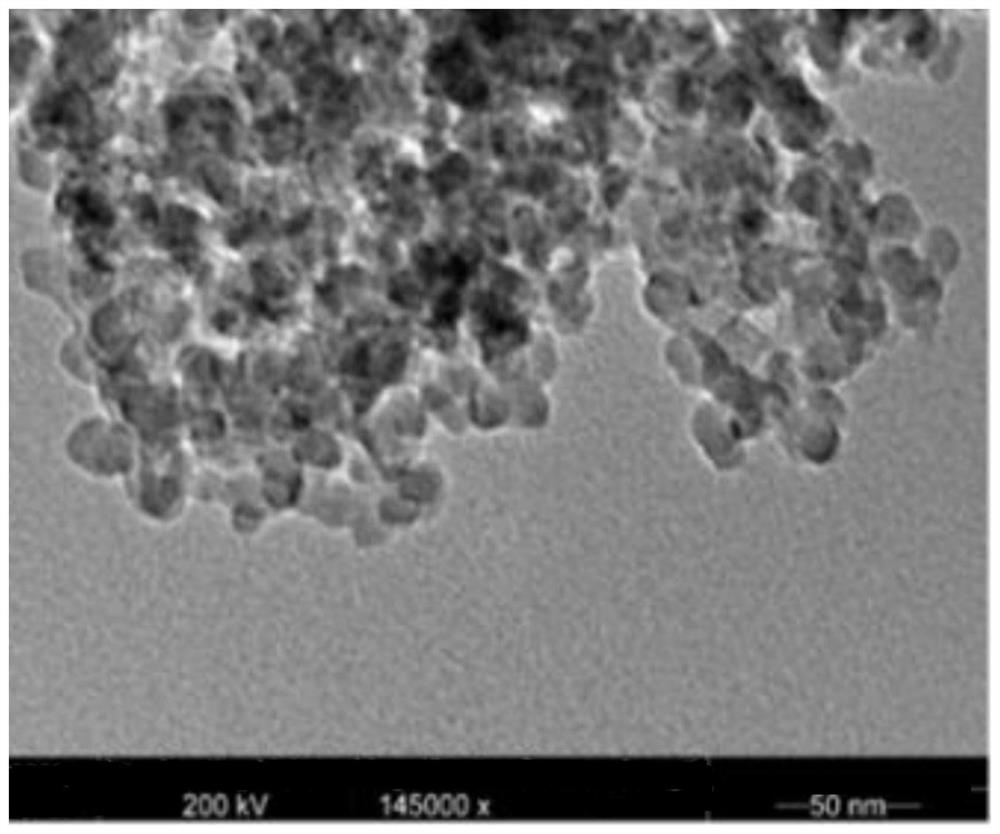

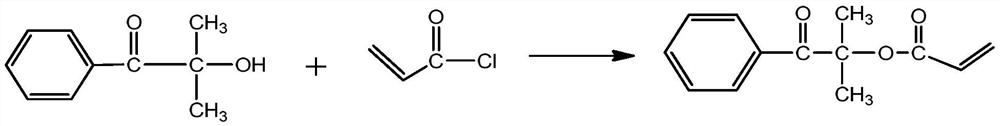

[0032] A fluorine-containing nano-SiO with photoinitiating activity 2 The preparation method of microsphere, comprises the following steps:

[0033] (1) Add 100mL of ethanol, 2.5g of ammonia water, and 16.2g of deionized water into a 250mL three-necked flask and stir them evenly. The alcohols are used as the reaction medium. Take 44.274g of trimethoxypropylaminosilane In a constant pressure funnel, add it dropwise to the above mixed solution at room temperature within 1 hour. After the dropwise addition, raise the temperature to 45°C, stir and react for 6 hours to obtain nano-silica microspheres with polymerizable groups on the surface Solution; wherein the concentrations of ammonia, water, and trimethoxypropylaminosilane in the entire solution are 0.9mol / L, 5.52mol / L, and 1.2mol / L, respectively.

[0034] (2) Feed nitrogen into the nano-silica microsphere solution prepared in step (1), use a constant pressure dropping funnel, and drop 56.8 g of heptadecafluorodecyltriethoxysi...

Embodiment 2

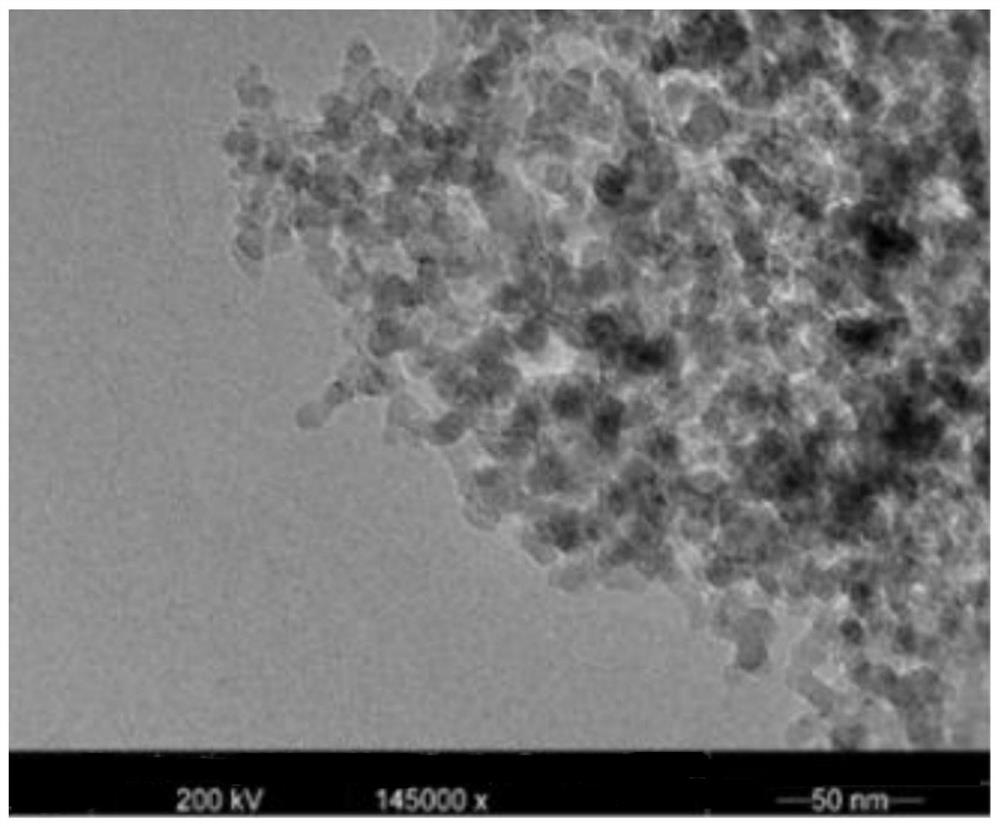

[0045] A fluorine-containing nano-SiO with photoinitiating activity 2 The preparation method of microsphere, comprises the following steps:

[0046] (1) Add 100mL of methanol, 1g of ammonia water, and 10g of deionized water into a 250mL three-necked flask, stir mechanically, and mix evenly. Take 22.137g of trimethoxypropylaminosilane in a constant pressure funnel and add it dropwise Add it to the above mixed solution within 1 hour at room temperature. After the dropwise addition, raise the temperature to 40°C, stir and react for 6 hours to obtain a solution of nano-silica microspheres with polymerizable groups on the surface; ammonia, water, trimethoxy The concentration of propylaminosilane in the whole solution is 0.44mol / L, 4.17mol / L and 0.75mol / L respectively;

[0047] (2) Nitrogen is passed to the nano-silica microsphere solution prepared in step (1), and a constant pressure dropping funnel is used to drop 56.8 g of heptadecylfluorodecyltriethoxysilane to the above soluti...

Embodiment 3

[0058] A fluorine-containing nano-SiO with photoinitiating activity 2 The preparation method of microsphere, comprises the following steps:

[0059] (1) Add 100mL of isopropanol, 0.5g of ammonia water, and 18g of deionized water into a 250mL three-necked flask, and mix them uniformly. 33.205 g of γ-mercaptopropyltrimethoxysilane was placed in a constant pressure funnel, and added dropwise to the above mixed solution at room temperature within 1 h. After the dropwise addition, the temperature was raised to 60°C, and the reaction was stirred for 3 hours to obtain a solution of nano-silica microspheres with polymerizable groups on the surface; wherein ammonia, water, and γ-mercaptopropyltrimethoxysilane accounted for the concentration of the entire solution respectively 0.19mol / L, 6.72mol / L and 1mol / L;

[0060] (2) Nitrogen is passed to the nano-silica microsphere solution prepared in step (1), and a constant pressure dropping funnel is used to drop 56.8 g of heptadecylfluorode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com