A kind of infrared reflective device and its preparation method

An infrared reflection and device technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of high cost, difficult industrial production and application, and cumbersome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

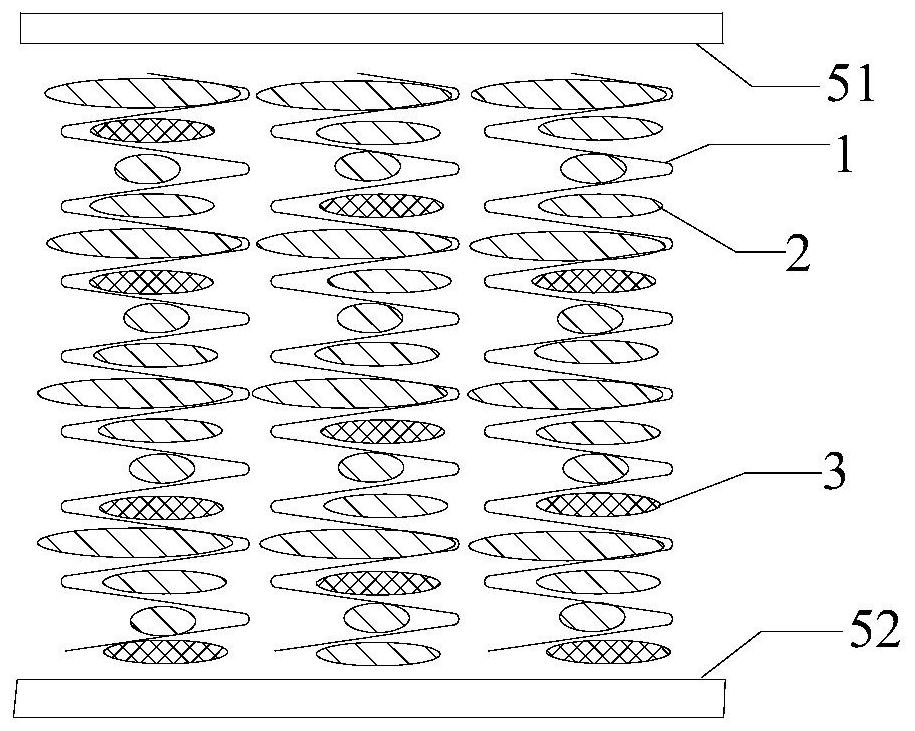

[0031] Under a yellow light environment, 27.07 parts by mass of potassium laurate, 6.17 parts by mass of n-decyl alcohol, and 66.76 parts by mass of heavy water were weighed and mixed uniformly to form a lyotropic liquid crystal for use.

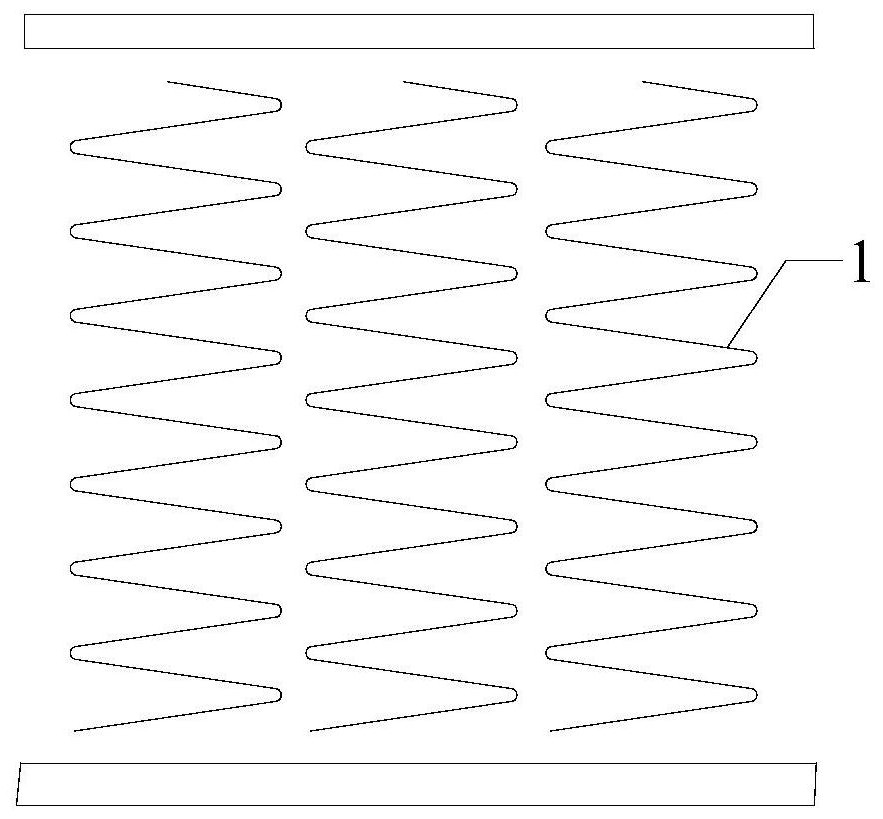

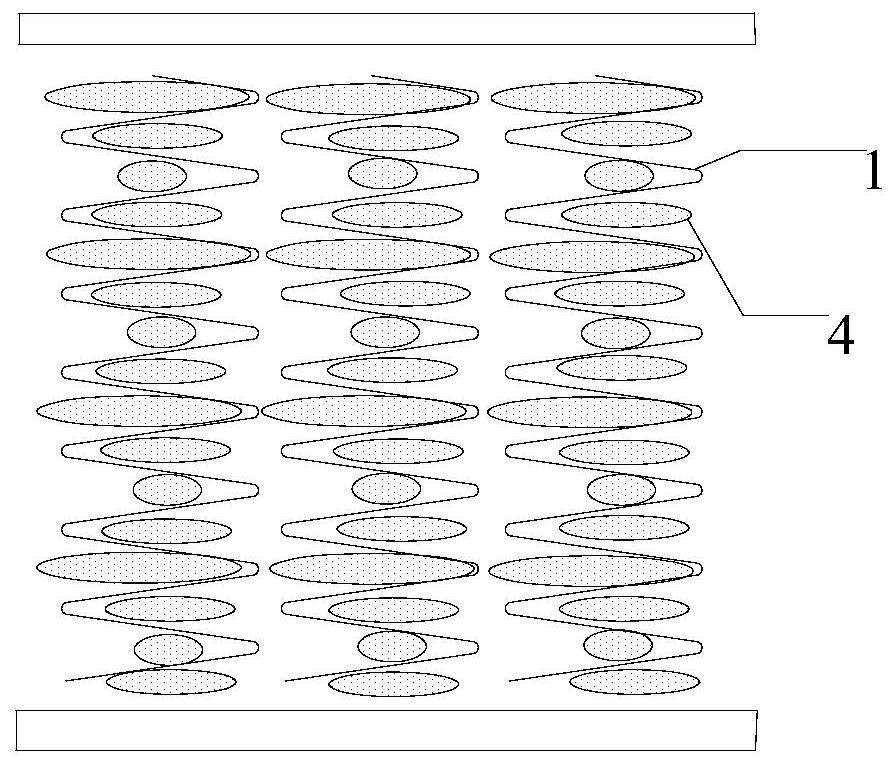

[0032] Weigh 80 parts by mass of negative mixed liquid crystal HNG30400-200 as liquid crystal one, 15 parts by mass of crosslinkable liquid crystal monomer HCM009, 4 parts by mass of left-handed chiral dopant S1011, 1 part by mass of photoinitiator Irgacure- 651 is placed in a brown bottle, and the brown bottle is heated to 70°C while stirring evenly at a speed of 40r / s to transform the liquid crystal material mixture into an isotropic liquid crystal mixture and reduce its viscosity. Then inject the liquid crystal material mixture into the liquid crystal cell at this temperature, cool down to room temperature naturally, and cure by ultraviolet light for 5 minutes.

[0033] Then it was soaked in cyclohexane organic solvent for 48 hours, and t...

Embodiment 2

[0045] An infrared reflective device, the difference from Example 1 is that the liquid crystal monomer uses HCM008, the photoinitiator uses Irgacure-2959, the liquid crystal one uses negative liquid crystal HTW138200-100, and the chiral dopant uses R1011.

Embodiment 3

[0047] An infrared reflective device, the difference from Example 1 is that the liquid crystal monomer uses HCM009, the photoinitiator uses Irgacure-369, the liquid crystal one uses negative liquid crystal MLC-2079, and the chiral dopant uses S811.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com