Preparation method of low-cost large-batch graphene

A graphene, large-scale technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as high cost, high technical difficulty, and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

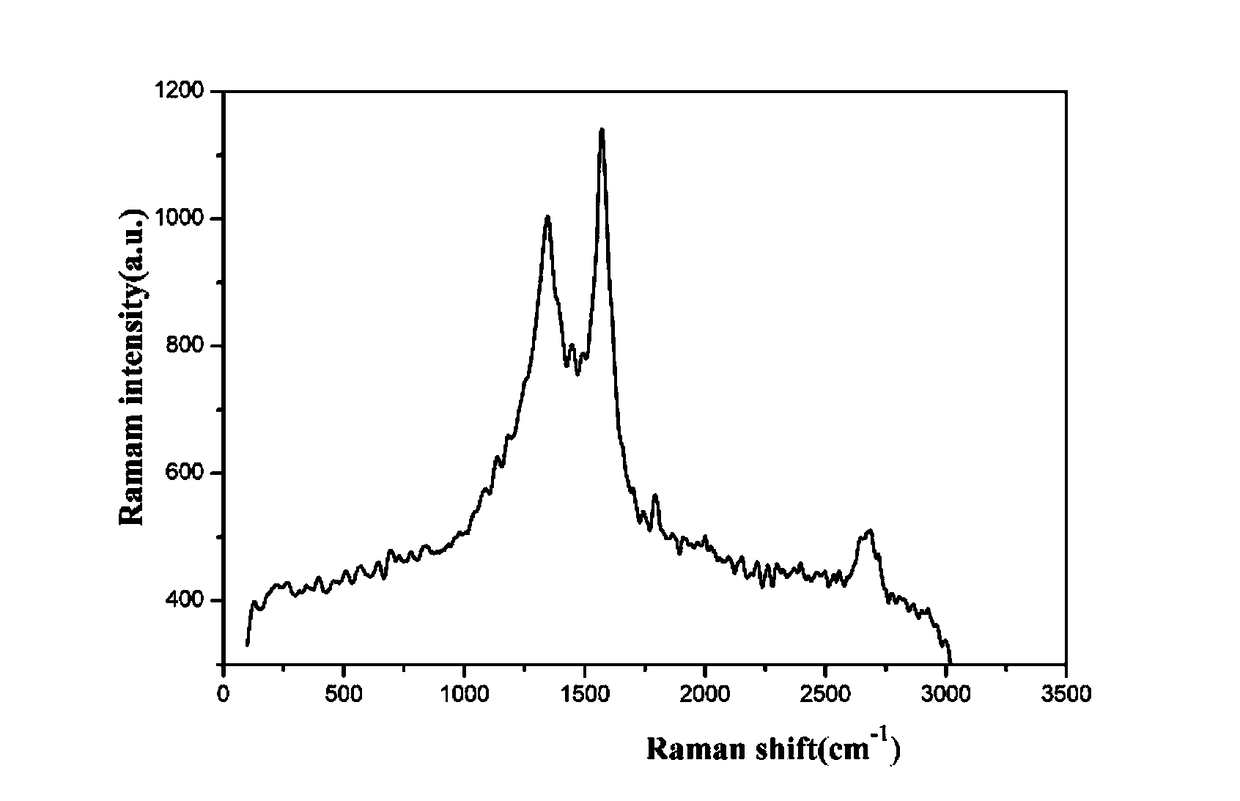

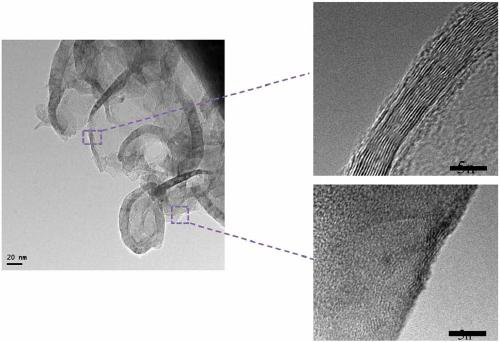

Image

Examples

specific Embodiment approach 1

[0015] Specific embodiment one: the preparation method of a kind of low-cost large-scale graphene of the present embodiment, it is to carry out according to the following steps:

[0016] 1. Add the matrix alloy into the crucible to melt, and adjust the temperature of the molten alloy to 550-750°C;

[0017] 2. Pass the gas with a flow rate of 300-10000mL / min into the molten alloy, and continuously carry out mechanical stirring during the process of passing the gas, and the stirring speed is 500-5000r / min;

[0018] 3. After the gas is introduced, the composite melt is solidified, the base alloy is corroded by dilute sulfuric acid with a volume concentration of 5% to 20%, and the impurities in the graphene solution are removed by suction filtration for many times, and the graphene is obtained after vacuum drying Powder;

[0019] The base alloy is pure magnesium, magnesium-zinc alloy, magnesium-calcium alloy or magnesium-lithium alloy; the gas is CO 2 Gas mixed with nitrogen in ...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of the mass of graphene generated to the magnesium participating in the reaction in the matrix alloy is 1:4. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the temperature of the alloy in the molten state is adjusted to 550-625°C. It is the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com