Non-autoclaved aerated phosphogypsum-based concrete block preparation method

A technology for concrete blocks and aerated phosphorus, applied in the field of building materials, can solve the problems of large one-time investment, easy cracking and high energy consumption, and achieve the effect of reducing investment, not easy to crack, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

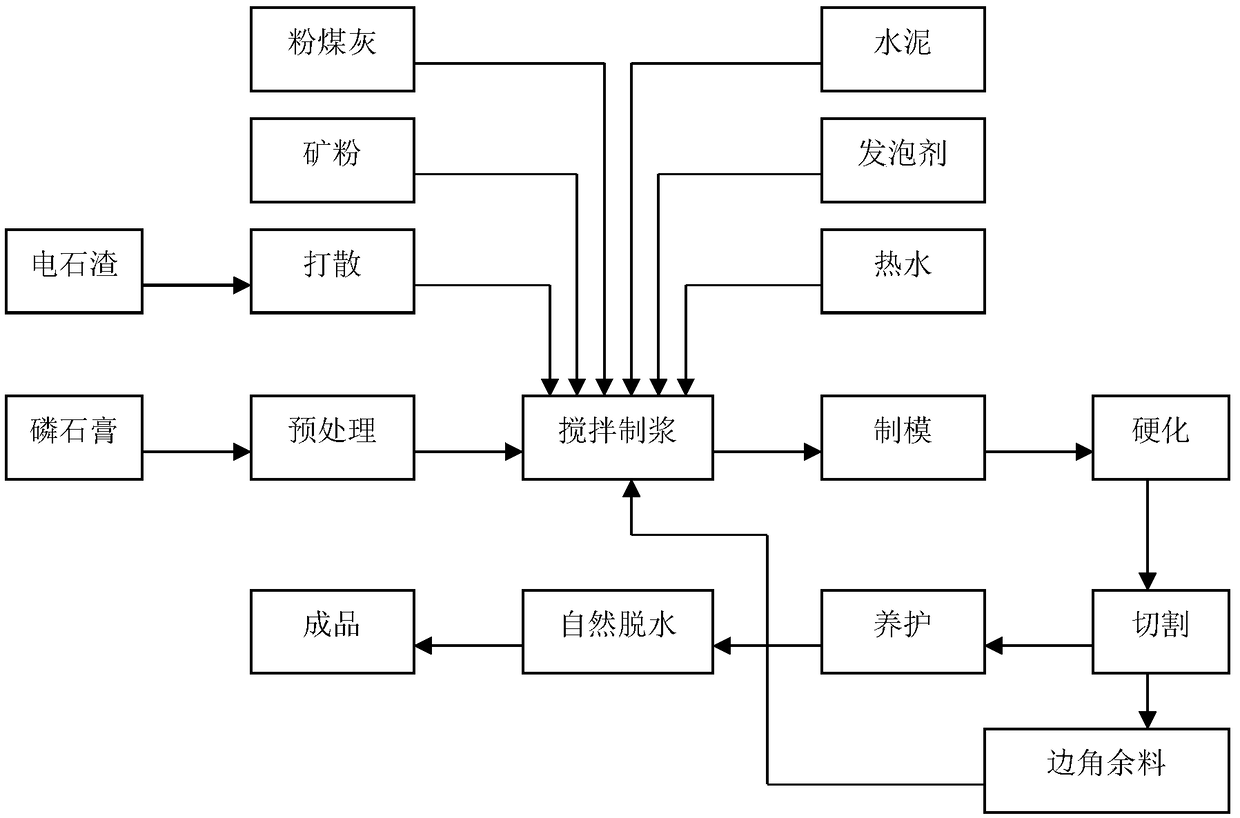

[0061] This embodiment discloses a method for preparing an autoclaved aerated phosphogypsum-based concrete block of the present invention. The process flow chart is as attached figure 1 As shown, it specifically includes the following steps:

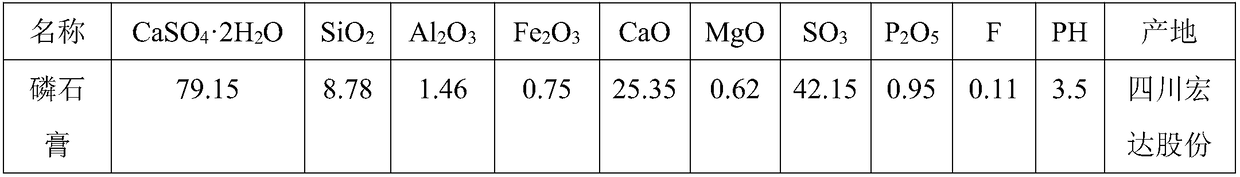

[0062] 1. Raw material pretreatment: The phosphogypsum produced by Sichuan Hongda is mechanically stirred and added with 4.5% calcium carbide slag, then it is aged for 5-7 days, and then it is crushed and finely crushed by a crushing machine. The measured PH=7.5. The pass rate of 30 mesh sieve is 97.5%, and the attached water content is 22.6%, ready for use;

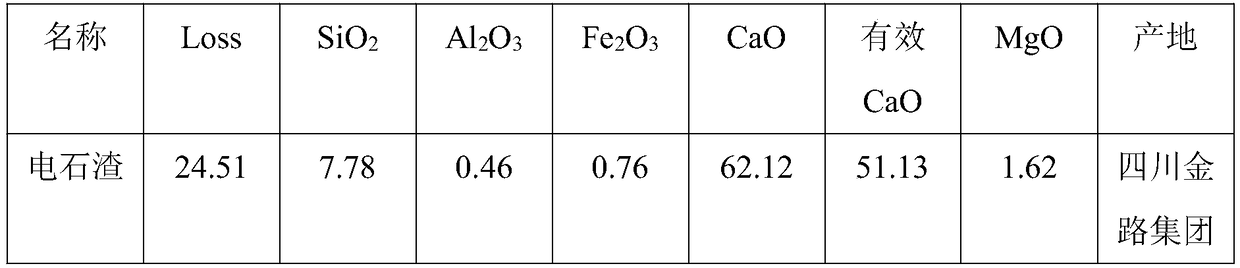

[0063] After the calcium carbide slag is broken up by a dispersing machine, the measured water content is 40.8%, and it is ready for use;

[0064] 2. Ingredients: Prepare the following raw materials in parts by weight: 40-60 parts of phosphogypsum, 5-15 parts of slag powder, 5-10 parts of calcium carbide slag, 5-15 parts of fly ash, 25-40 parts of cement, 0.1- of silica sol 0.15 parts, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com