Phase-change-controllable totally-inorganic perovskite thin film preparation method and device application

A technology for film preparation and inorganic calcium, which is applied in the field of all-inorganic perovskite film preparation to achieve simple process conditions, reduce defect state density, and improve crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

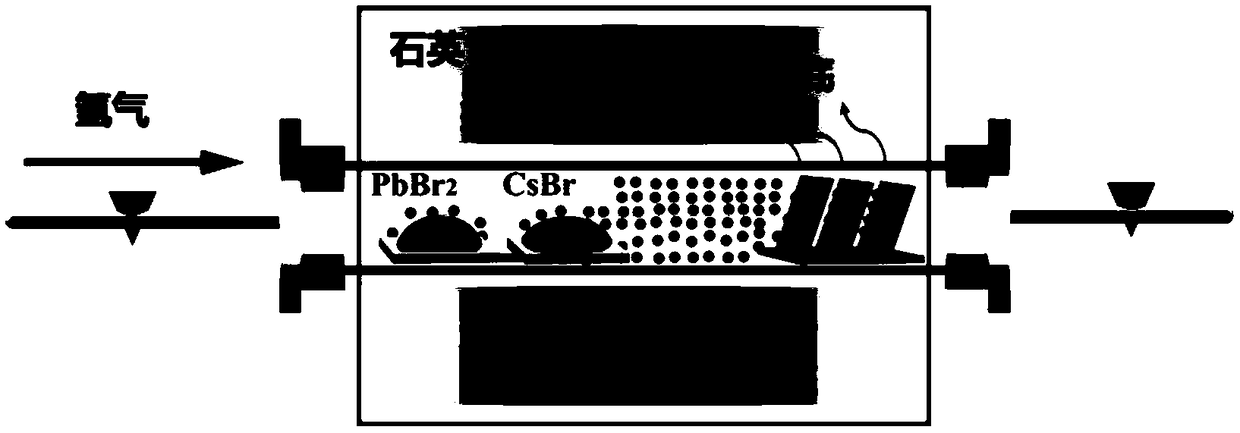

[0032] The vapor deposition device used in this example and the principle of preparing perovskite film by chemical vapor deposition are as follows figure 1 shown. All adopt chemical vapor deposition (CVD) device in the embodiment, and reactant is cesium bromide and lead bromide, and purity is all more than 99%, and carrier gas is argon, and purity is more than 99%, and substrate material selects silicon for use, P type, (100) crystal plane. In the device fabrication process, interdigitated electrodes are used as the substrate, and the electrode material is gold. All are commercially available products.

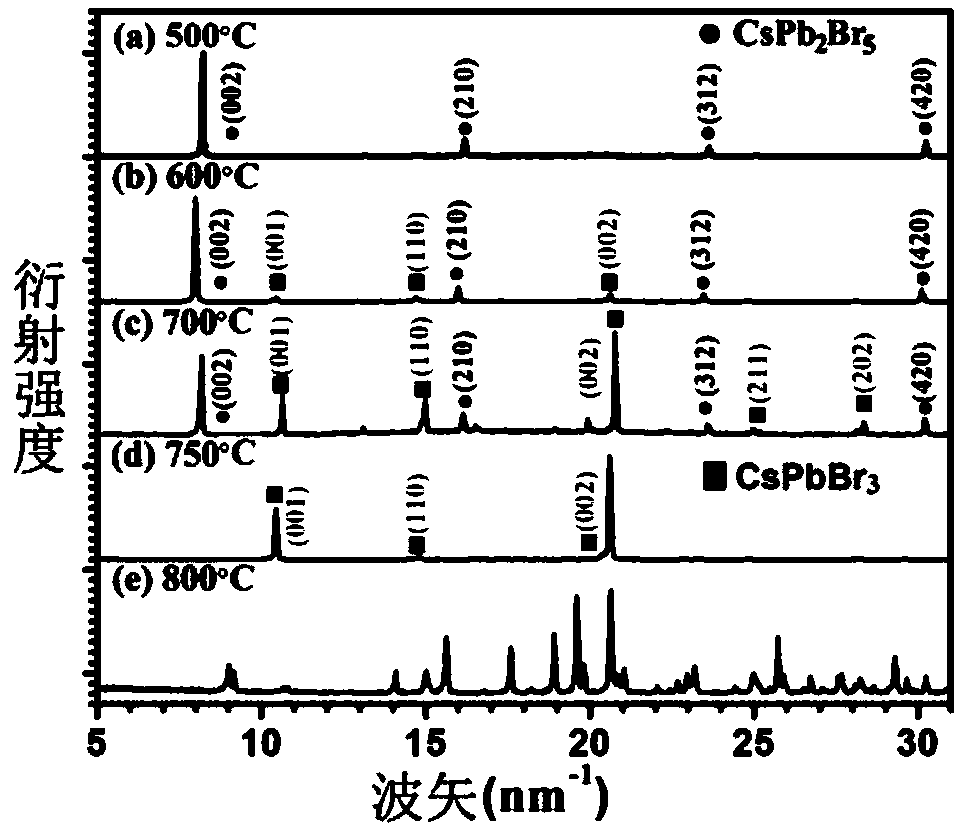

[0033] Growth of CsPb by CVD Technique 2 Br 5 Perovskite thin film materials:

[0034] 1. The reactant cesium bromide and lead bromide are respectively placed in the CVD system, and the substrate is placed in the deposition area, which is conducive to the reaction and deposition of gas phase substances;

[0035] 2. Start the mechanical pump, evacuate to 100Pa, repeat thr...

Embodiment 2

[0042] The vapor deposition device and raw materials of this embodiment are the same as those of Embodiment 1.

[0043] Growth of CsPb by CVD Technique 2 Br 5 -CsPbBr 3 Dual-phase perovskite thin film materials

[0044] Preparation steps and processing conditions are as described in Example 1, the difference is:

[0045] Process conditions: the growth temperature is 600° C., the heating time from room temperature to 600° C. is 60 minutes, the reaction time at this temperature is 40 minutes, and the flow rate of the carrier gas is 80 sccm.

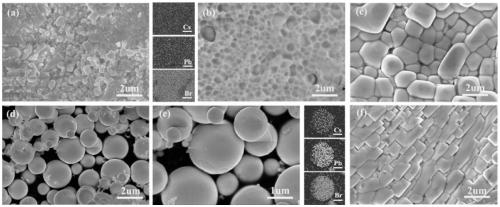

[0046] Such as figure 2 As shown in b, the perovskite prepared at 600°C is CsPb 2 Br 5 -CsPbBr 3 Dual-phase structure, that is, CsPbBr starts to appear in the perovskite 3 Mutually. Such as image 3b It is known that the surface of the perovskite film is relatively uniform and the particle size increases

[0047] Deposit the above perovskite thin film on the interdigitated electrodes of the silicon substrate, and the electrode m...

Embodiment 3

[0049] The vapor deposition device and raw materials of this embodiment are the same as those of Embodiment 1.

[0050] Growth of CsPb2Br5-CsPbBr3 Dual Phase Perovskite Thin Films by CVD

[0051] Preparation steps and processing conditions are as described in Example 1, the difference is:

[0052] Process conditions: the growth temperature is 700° C., the heating time from room temperature to 700° C. is 60 minutes, the reaction time at this temperature is 40 minutes, and the flow rate of the carrier gas is 80 sccm.

[0053] Such as figure 2 As shown in c, the perovskite prepared at 700°C is CsPb 2 Br 5 -CsPbBr 3 Duplex structure, CsPbBr 3 Significantly increased relative gravity. Such as image 3 It can be seen from c that the particle size on the surface of the perovskite film is relatively large.

[0054] Deposit the above perovskite thin film on the interdigitated electrodes of the silicon substrate, and the electrode material is gold to obtain a perovskite photoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com