Spherical lithium iron phosphate coated lithium nickelate-cobaltate-manganate battery material and preparation method

A technology of nickel cobalt lithium manganate and lithium iron phosphate, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor thermal stability and high rate stability, and achieves improved compaction density, low cost, and improved Effect of charge-discharge capacity and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

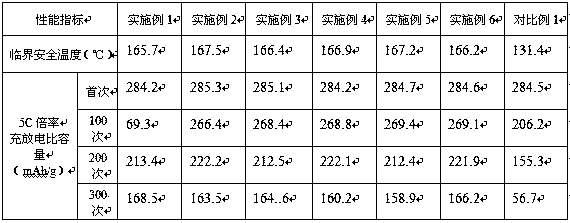

Examples

Embodiment 1

[0034] The preparation process is:

[0035] (1) Add nickel sulfate, cobalt sulfate, manganese sulfate and potassium permanganate into deionized water and fully dissolve to obtain a mixed solution; in the mixed solution, the molar ratio of nickel sulfate, cobalt sulfate, manganese sulfate and potassium permanganate for n (NiSO 4 ): n (CoSO 4 ):n(MnSO 4 ):n(KMnO 4 )=5:5:2:3, the mass concentration of the mixed solution is 32%;

[0036](2) Dissolve lithium hydroxide in deionized water to prepare a solution with a mass concentration of 15%, and then add it dropwise to the mixed solution prepared in step (1), and add porous carbon nanospheres, and stir for 15 minutes to obtain a suspension Turbid liquid; in the suspension, 58 parts by weight of mixed solution, 5 parts by weight of lithium hydroxide, 13 parts by weight of deionized water, and 26 parts by weight of porous carbon nanospheres;

[0037] (3) Transfer the suspension prepared in step (2) to a microwave reactor, and co...

Embodiment 2

[0046] The preparation process is:

[0047] (1) Add nickel sulfate, cobalt sulfate, manganese sulfate and potassium permanganate into deionized water and fully dissolve to obtain a mixed solution; in the mixed solution, the molar ratio of nickel sulfate, cobalt sulfate, manganese sulfate and potassium permanganate for n (NiSO 4 ): n (CoSO 4 ):n(MnSO 4 ):n(KMnO 4 )=5:5:2:3, the mass concentration of the mixed solution is 37%;

[0048] (2) Dissolve lithium hydroxide in deionized water to make a solution with a mass concentration of 12%, and then add it dropwise to the mixed solution prepared in step (1), and add porous carbon nanospheres, and stir for 10-30 minutes to prepare Obtain the suspension; in the suspension, 51 parts by weight of the mixed solution, 6 parts by weight of lithium hydroxide, 14 parts by weight of deionized water, and 29 parts by weight of porous carbon nanospheres;

[0049] (3) Transfer the suspension prepared in step (2) to a microwave reactor, and c...

Embodiment 3

[0058] The preparation process is:

[0059] (1) Add nickel sulfate, cobalt sulfate, manganese sulfate and potassium permanganate into deionized water and fully dissolve to obtain a mixed solution; in the mixed solution, the molar ratio of nickel sulfate, cobalt sulfate, manganese sulfate and potassium permanganate for n (NiSO 4 ): n (CoSO 4 ):n(MnSO 4 ):n(KMnO 4 )=5:5:2:3, the mass concentration of the mixed solution is 34%;

[0060] (2) Dissolve lithium hydroxide in deionized water to make a solution with a mass concentration of 20%, and then add it dropwise to the mixed solution prepared in step (1), and add porous carbon nanospheres, and stir for 18 minutes to obtain a suspension Turbid liquid; in the suspension, 571 parts by weight of mixed solution, 5 parts by weight of lithium hydroxide, 13 parts by weight of deionized water, and 27 parts by weight of porous carbon nanospheres;

[0061] (3) Transfer the suspension prepared in step (2) to a microwave reactor, and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com