Preparation method of tonalide intermediate HMT

A technology for spitting musk and intermediates, which is applied in the field of preparation of spitting musk intermediate HMT, which can solve the problems of environmental pollution of production materials, unsatisfactory reaction yield, and difficulty in obtaining materials, so as to reduce the use of solvents and the generation of reaction products. Fewer by-products and the effect of reducing the generation of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

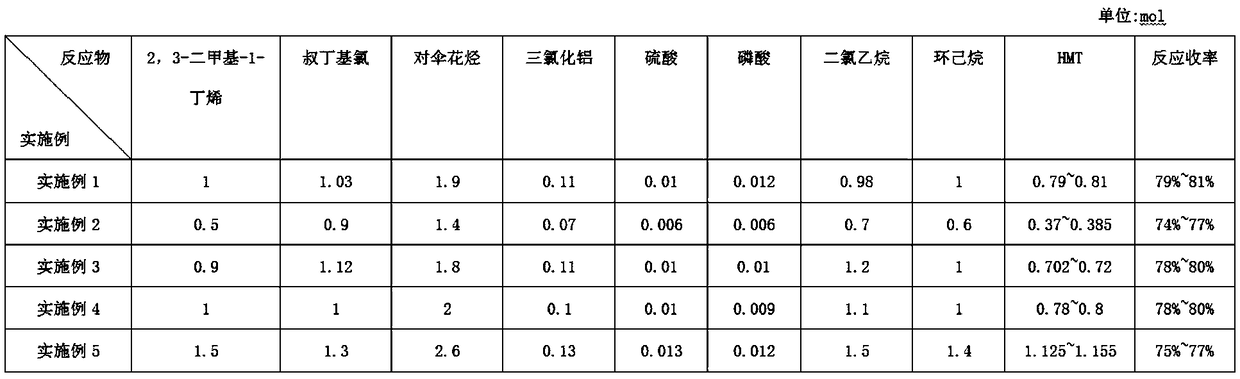

[0029] Example 2, with 0.5mol of 2,3-dimethyl-1-butene as raw material, put in the corresponding materials in the following molar ratios;

[0030] 2,3-Dimethyl-1-butene: tert-butyl chloride: p-cymene: aluminum chloride: sulfuric acid: phosphoric acid: dichloroethane: cyclohexane = 0.5:0.9:1.4:0.07:0.006 :0.006:0.7:0.6; Put p-cymene, sulfuric acid, phosphoric acid and aluminum trichloride into the reaction kettle in proportion to mix; then mix 2,3-dimethyl-1-butene with tert-butyl chloride Add it dropwise into the reaction kettle, and react at room temperature for 1 hour to generate 0.370mol-0.385mol of Tuna musk intermediate HMT; the reaction yield is about 74%-77%;

[0031] Then all the reacted substances are transferred to the distillation tower, and the distillation separation and recovery are carried out according to the following steps;

[0032] S1. Control the air pressure of the rectification tower at normal pressure and the temperature at 85°C to 93°C to recover dichl...

Embodiment 3

[0037] Embodiment 3, with 0.9mol of 2,3-dimethyl-1-butene as raw material, put in the corresponding materials in the following molar ratios;

[0038] 2,3-Dimethyl-1-butene: tert-butyl chloride: p-cymene: aluminum chloride: sulfuric acid: phosphoric acid: dichloroethane: cyclohexane = 0.9:1.12:1.8:0.11:0.01 :0.01:1.2:1; Put p-cymene, sulfuric acid, phosphoric acid and aluminum trichloride into the reaction kettle in proportion to mix; then mix 2,3-dimethyl-1-butene with tert-butyl chloride Add it dropwise into the reaction kettle, and react at room temperature for 1 hour to generate 0.702 mol-0.720 mol of Tuna musk intermediate HMT; the reaction yield is about 78%-80%;

[0039] Then all the reacted substances are transferred to the distillation tower, and the distillation separation and recovery are carried out according to the following steps;

[0040] S1. Control the air pressure of the rectification tower at normal pressure and the temperature at 85°C to 93°C to recover dic...

Embodiment 4

[0045] Embodiment 4, with 1mol of 2,3-dimethyl-1-butene as raw material, put in the corresponding materials in the following molar ratios;

[0046]2,3-Dimethyl-1-butene: tert-butyl chloride: p-cymene: aluminum chloride: sulfuric acid: phosphoric acid: dichloroethane: cyclohexane = 1:1:2:0.1:0.01 :0.009:1.1:1; Put p-cymene, sulfuric acid, phosphoric acid and aluminum trichloride into the reaction kettle in proportion to mix; then mix 2,3-dimethyl-1-butene with tert-butyl chloride Add it dropwise into the reaction kettle, and react at room temperature for 1 hour to generate 0.78mol-0.80mol of Tuna musk intermediate HMT; the reaction yield is about 78%-80%;

[0047] Then all the reacted substances are transferred to the distillation tower, and the distillation separation and recovery are carried out according to the following steps;

[0048] S1. Control the air pressure of the rectification tower at normal pressure and the temperature at 85°C to 93°C to recover dichloroethane an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com