Turnable ethylene-propylene-diene rubber heat insulating layer material and preparation method thereof

A technology of EPDM rubber and thermal insulation layer, which is applied in the field of thermal insulation material products, can solve the problems of uniform mixing of components, human harm of dispersive asbestos, supply disconnection, etc., and achieve uniform mixing and supply source. Guaranteed and environmentally friendly components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

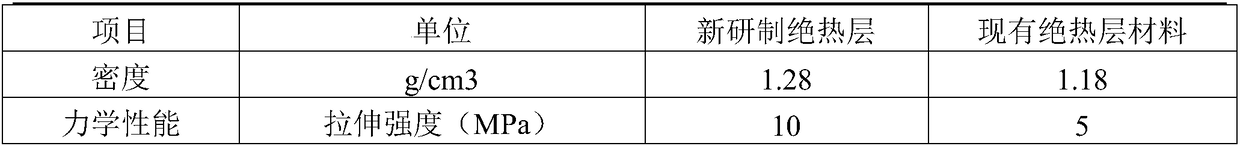

[0031] The matrix components and formulations of the insulation materials used are shown in Table 4.

[0032] Table 4 Components and formula of heat insulation material matrix

[0033] serial number

Matrix components

Proportion (weight)

effect

1

EPDM

100

base rubber

2

Zinc oxide

5

activator

3

0.6

plasticizer, activator

4

boron phenolic resin

20

Ablation-resistant filler, carbon forming agent

5

70

Ablation-resistant, flame-retardant, hardening filler

6

4

Ablation-resistant filler, carbonation agent

7

30

Reinforcing agent

8

Antimony oxide

3

flame retardant

9

8

flame retardant

10

dicumyl per...

Embodiment 2

[0043] The matrix components and formulations of the insulation materials used are shown in Table 6.

[0044] Table 6 Insulation material matrix components and formulations

[0045] serial number

Matrix components

Proportion (weight)

effect

1

EPDM

100

base rubber

2

Zinc oxide

5

activator

3

stearic acid

0.6

plasticizer, activator

4

boron phenolic resin

22

Ablation-resistant filler, carbon forming agent

5

Silicon carbide nanofiller

75

Ablation-resistant, flame-retardant, hardening filler

6

6

Ablation-resistant filler, carbonation agent

7

fumed silica

35

Reinforcing agent

8

Antimony oxide

7

flame retardant

9

10

flame retardant

10

dicumyl perox...

Embodiment 3

[0055] The matrix components and formulations of the insulation materials used are shown in Table 8.

[0056] Table 8 Insulation material matrix components and formulations

[0057]

[0058]

[0059]The manufacturing method process of the thermal insulation material involved in the present invention is:

[0060] (1) Cutting of EPDM rubber and aramid fiber: Cut EPDM rubber into blocks on the rubber cutting machine as required, and cut aramid fiber on the shredding machine, with a length of 3 to 5mm ;

[0061] (2) Weigh each component: Weigh 100 parts of EPDM rubber, 0.6 parts of stearic acid, 5 parts of zinc oxide, 25 parts of boron phenolic resin, 40 parts of fumed silica, and 80 parts of silicon carbide nanofiller according to the formula. parts, 8 parts of aramid fiber, 10 parts of antimony oxide, 12 parts of decabromodiphenyl ether, 8 parts of dicumyl peroxide and other components.

[0062] (3) Preparation of EPDM rubber: Pass the cut EPDM rubber at least 3 times f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ablation rate | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com