High temperature resistant cathode electrophoretic coating and preparation method thereof

A cathodic electrophoretic coating and high temperature resistant technology, applied in the field of coatings, can solve the problems of poor coating film coverage of edges and corners and tips, and achieve the effects of improving swimming penetration, uniform coating film and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

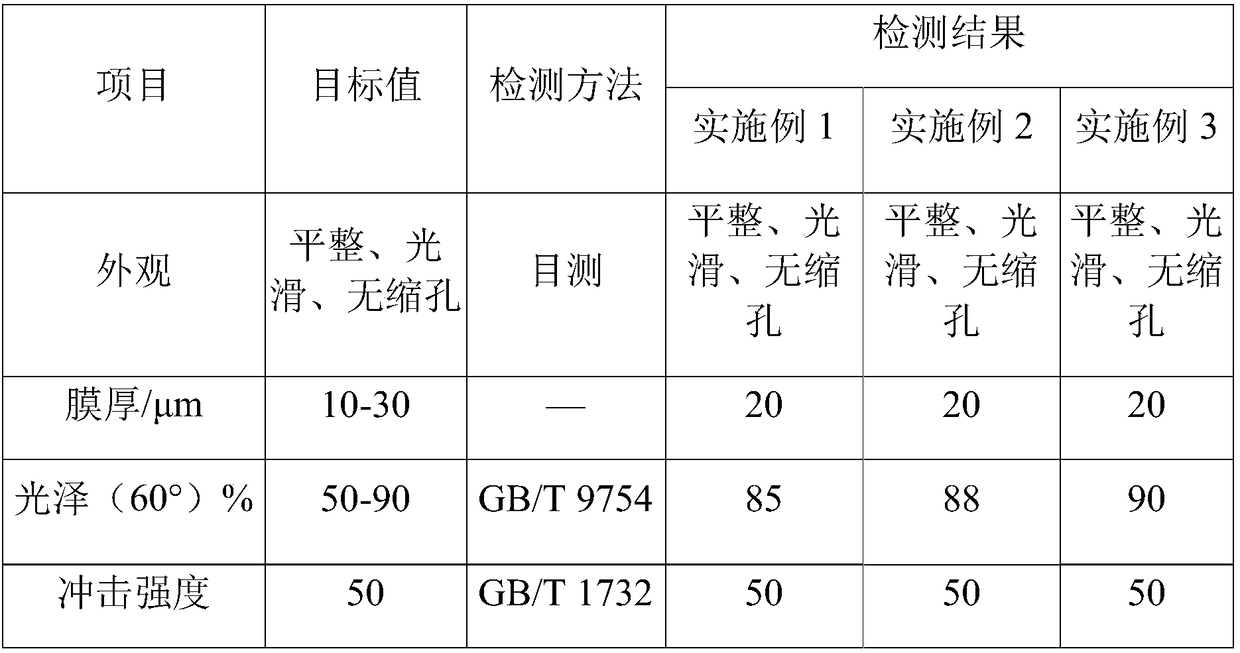

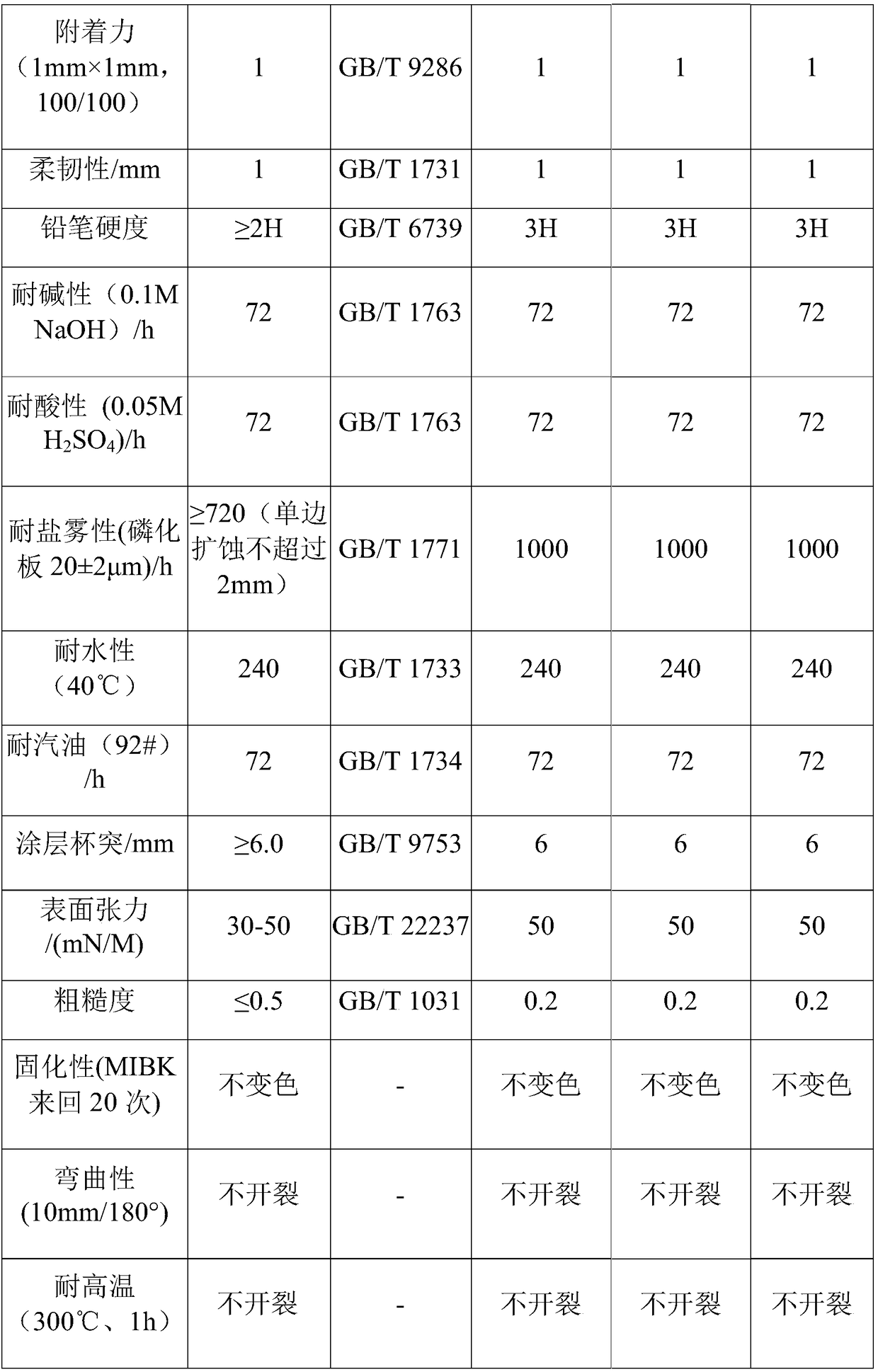

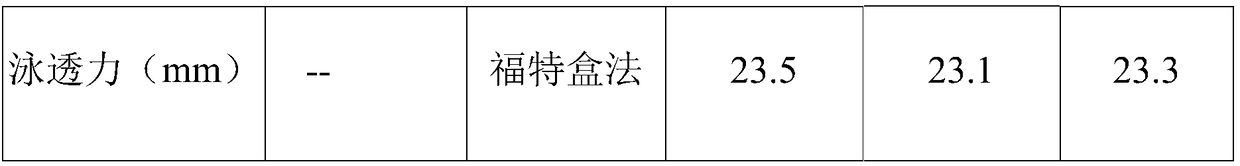

Examples

Embodiment 1

[0034] The embodiment of the present invention provides a high-temperature-resistant cathodic electrophoretic coating. The raw materials include the following components in parts by weight: 10 parts of color paste, 30 parts of emulsion, and 50 parts of deionized water;

[0035] The color paste includes the following components in parts by mass: 20 parts of acrylic modified cationic silicone resin, 6 parts of n-butanol, 3 parts of oxalic acid, 0.4 parts of alkylphenol polyoxyethylene ether, 45 parts of deionized water, 15 parts of titanium dioxide, 15 parts of bentonite;

[0036] The emulsion comprises the following components in parts by mass: 25 parts of acrylic modified cationic silicone resin, 1 part of FS-204 nonionic surfactant, 0.5 part of oxalic acid and 55 parts of deionized water.

[0037] The above-mentioned acrylic acid-modified cationic silicone resin is calculated in parts by mass, and the raw materials include the following components: 30 parts of silicone resin,...

Embodiment 2

[0046] The embodiment of the present invention provides a high-temperature-resistant cathodic electrophoretic coating. The raw materials include the following components in parts by weight: 10 parts of color paste, 40 parts of emulsion, and 60 parts of deionized water;

[0047] The color paste includes the following components in parts by mass: 30 parts of acrylic modified cationic silicone resin, 3 parts of ethylene glycol ether, 5 parts of sulfamic acid, 0.05 part of alkylphenol polyoxyethylene ether, deionized water 30 parts, 15 parts of chrome yellow 7000 and 20 parts of barium sulfate;

[0048] The emulsion comprises the following components in parts by mass: 30 parts of acrylic modified cationic silicone resin, 5 parts of polypropylene glycol PPG1000 emulsifier, 2 parts of sulfamic acid and 35 parts of deionized water.

[0049] The above-mentioned acrylic modified cationic silicone resin is calculated in parts by mass, and the raw materials include the following componen...

Embodiment 3

[0058] The embodiment of the present invention provides a high-temperature-resistant cathodic electrophoretic paint. The raw materials include the following components in parts by weight: 10 parts of color paste, 50 parts of emulsion, and 40 parts of pure water;

[0059] The color paste includes the following components in parts by mass: 40 parts of acrylic modified cationic silicone resin, 10 parts of dipropylene glycol methyl ether and ethylene glycol hexyl ether (mass ratio is 2:1), 0.5 parts of lactic acid, alkane 0.8 parts of phenolic polyoxyethylene ether, 40 parts of deionized, 15 parts of titanium dioxide, 10 parts of talcum powder;

[0060] The emulsion comprises the following components in parts by mass: 35 parts of acrylic modified cationic silicone resin, 3 parts of nonylphenol polyoxyethylene ether TX-15, 5 parts of lactic acid and 40 parts of deionized water.

[0061] The above-mentioned acrylic acid-modified cationic silicone resin is calculated in parts by mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com