Near-ultraviolet effective excitation green phosphor and preparation method and application thereof

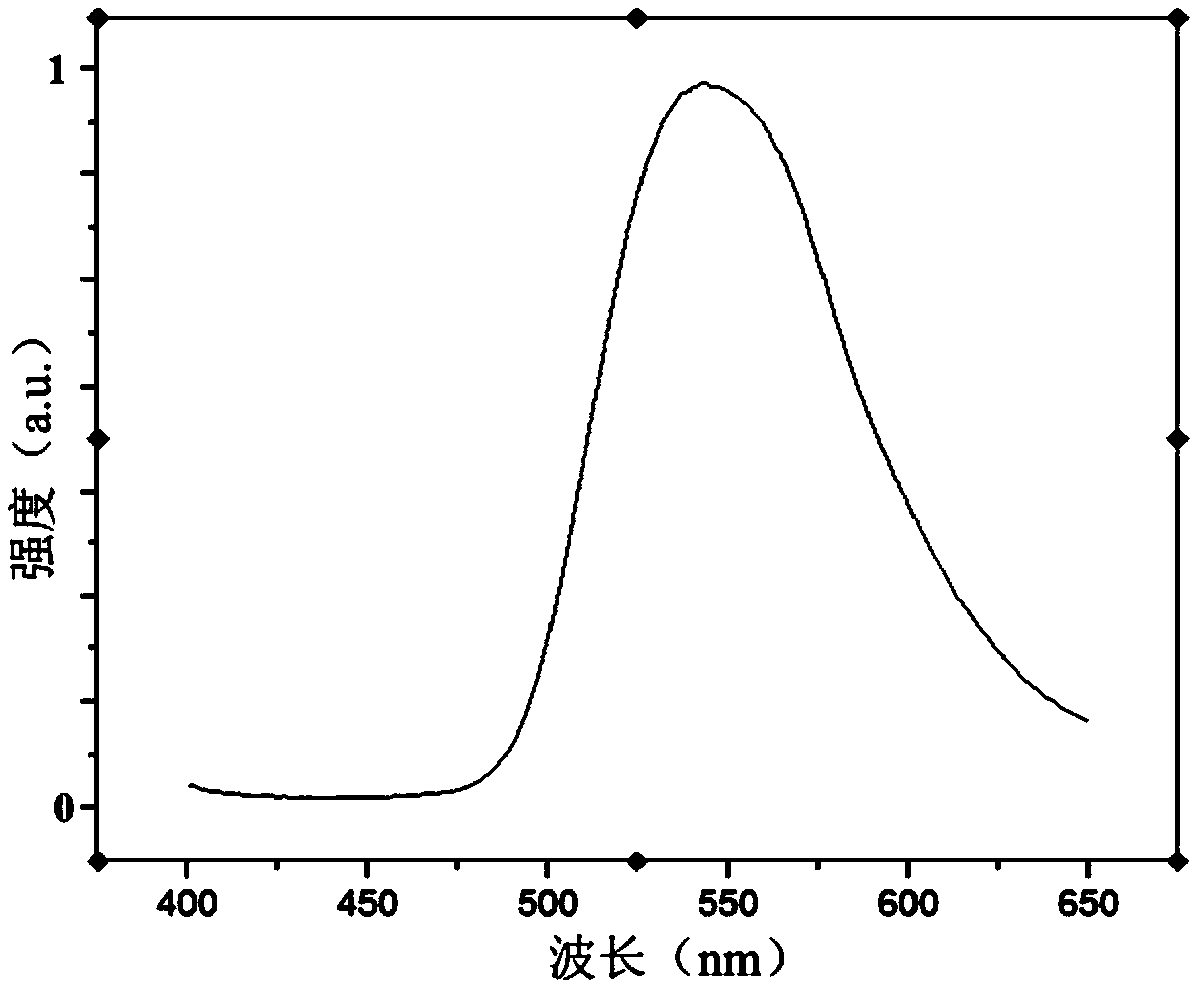

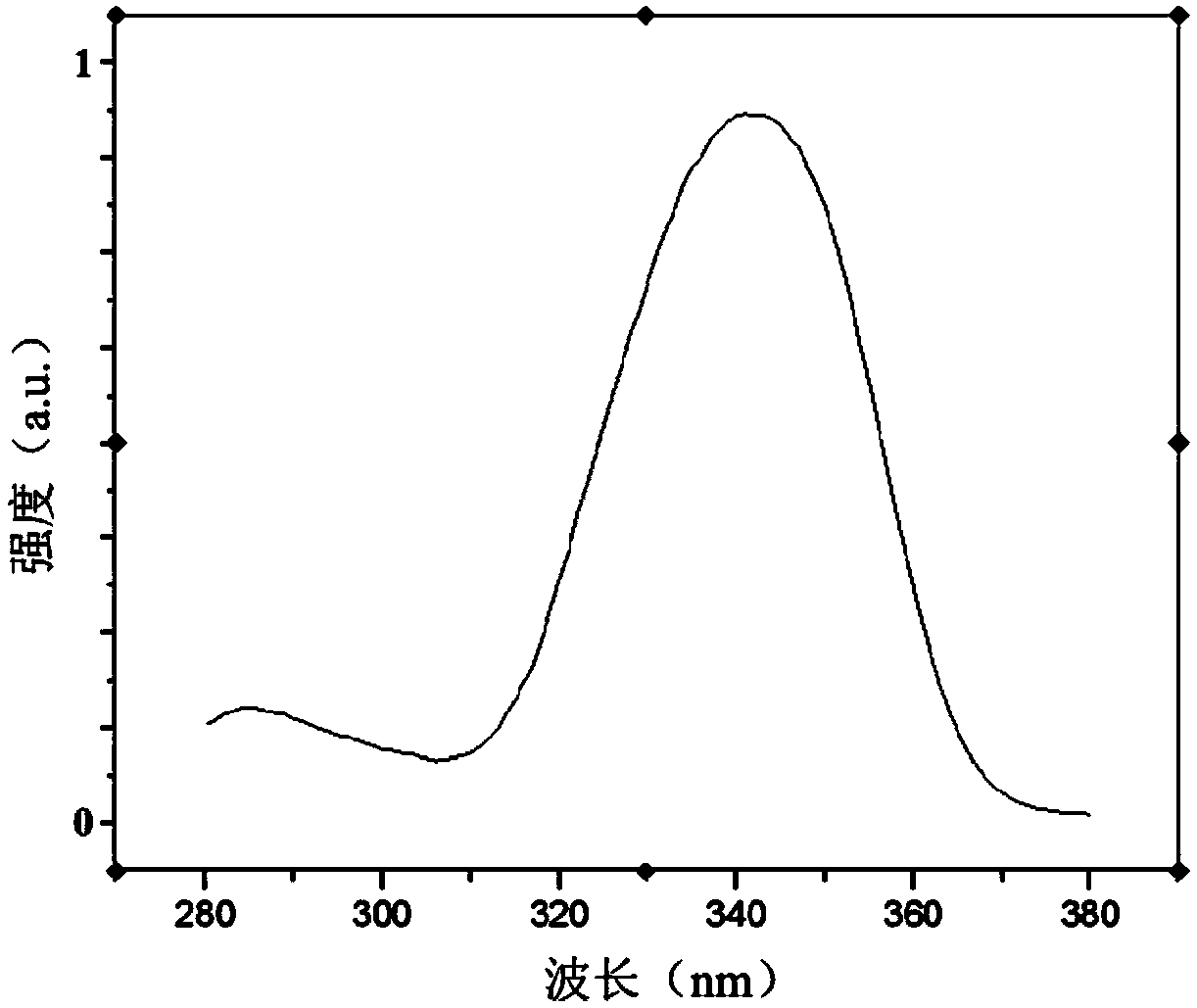

A green phosphor, near-ultraviolet technology, applied in the field of green phosphor, can solve the problems of large emission color temperature drift, mismatched excitation light source, low luminous efficiency, etc., achieves good chemical stability, low production conditions and equipment requirements, The effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

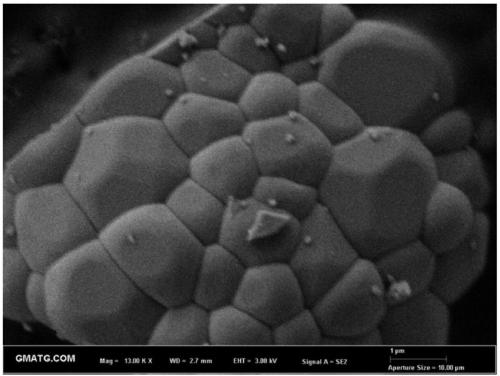

[0042] A compositional expression for Y 2.92 Al 5 o 12 :0.08Ce 3+ The preparation method of the green fluorescent powder that the near-ultraviolet effectively excites comprises the following steps:

[0043] 1) Follow Y 2.92 Al 5 o 12 :0.08Ce 3+ The stoichiometric ratio weighs yttrium oxide, cerium oxide and aluminum oxide;

[0044] 2) Mix yttrium oxide, cerium oxide and aluminum oxide weighed in step 1), add citric acid and 25% dilute nitric acid, and conduct a heating reaction at 80° C. for 6 hours to obtain a gel;

[0045] 3) The gel obtained in step 2) is dried using a two-step optimization method. The first step is pre-dried at a temperature of 80°C, and the pre-drying time is 6h; the second step is carried out at a temperature of 120°C Steady drying treatment, the time of steady drying treatment is 12 hours, and a fluffy foamy solid is obtained;

[0046] 4) The fluffy foamy solid obtained in step 3) is sintered by a segmented treatment method. In the first stage,...

Embodiment 2

[0053] A compositional expression for Y 2.91 Al 5 o 12 :0.09Ce 3+ The preparation method of the green fluorescent powder that the near-ultraviolet effectively excites comprises the following steps:

[0054] 1) Follow Y 2.91 Al 5 o 12 :0.09Ce 3+ The stoichiometric ratio weighs yttrium oxide, cerium oxide and aluminum oxide;

[0055] 2) Mix yttrium oxide, cerium oxide and aluminum oxide weighed in step 1), add citric acid and 10% dilute nitric acid, and conduct a heating reaction at 60° C. for 12 hours to obtain a gel;

[0056] 3) The gel obtained in step 2) is dried using a two-step optimization method. The first step is pre-dried at a temperature of 60°C, and the pre-drying time is 12h; the second step is carried out at a temperature of 110°C Steady drying treatment, the time of firm drying treatment is 24 hours, and a fluffy foamy solid is obtained;

[0057] 4) The fluffy foamy solid obtained in step 3) is sintered by adopting a segmented treatment method. In the fir...

Embodiment 3

[0060] A compositional expression for Y 2.94 Al 5 o 12 :0.06Ce 3+ The preparation method of the green fluorescent powder that the near-ultraviolet effectively excites comprises the following steps:

[0061] 1) Follow Y 2.94 Al 5 o 12 :0.06Ce 3+ The stoichiometric ratio weighs yttrium oxide, cerium oxide and aluminum oxide;

[0062] 2) Mix yttrium oxide, cerium oxide and aluminum oxide weighed in step 1), add citric acid and 30% dilute nitric acid, and conduct a heating reaction at 70° C. for 8 hours to obtain a gel;

[0063] 3) Use a two-step optimization method to dry the gel obtained in step 2). The first step is to pre-dry at a temperature of 90°C, and the pre-drying time is 4h; the second step is to carry out at a temperature of 130°C Stable drying treatment, the time of firm drying treatment is 8 hours, and a fluffy foamy solid is obtained;

[0064] 4) The fluffy foamy solid obtained in step 3) is sintered by adopting a segmented treatment method, the first stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com