Diamond-like coating piston ring and preparation method thereof

A diamond coating and piston ring technology, applied in the field of piston rings, can solve the problems affecting the wear resistance of diamond-like carbon, high temperature stability, high hardness of diamond-like coating, and difficult to guarantee the bonding force, etc. Anti-peeling ability, increase practicality, reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A diamond-like coating piston ring and a preferred embodiment of the preparation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

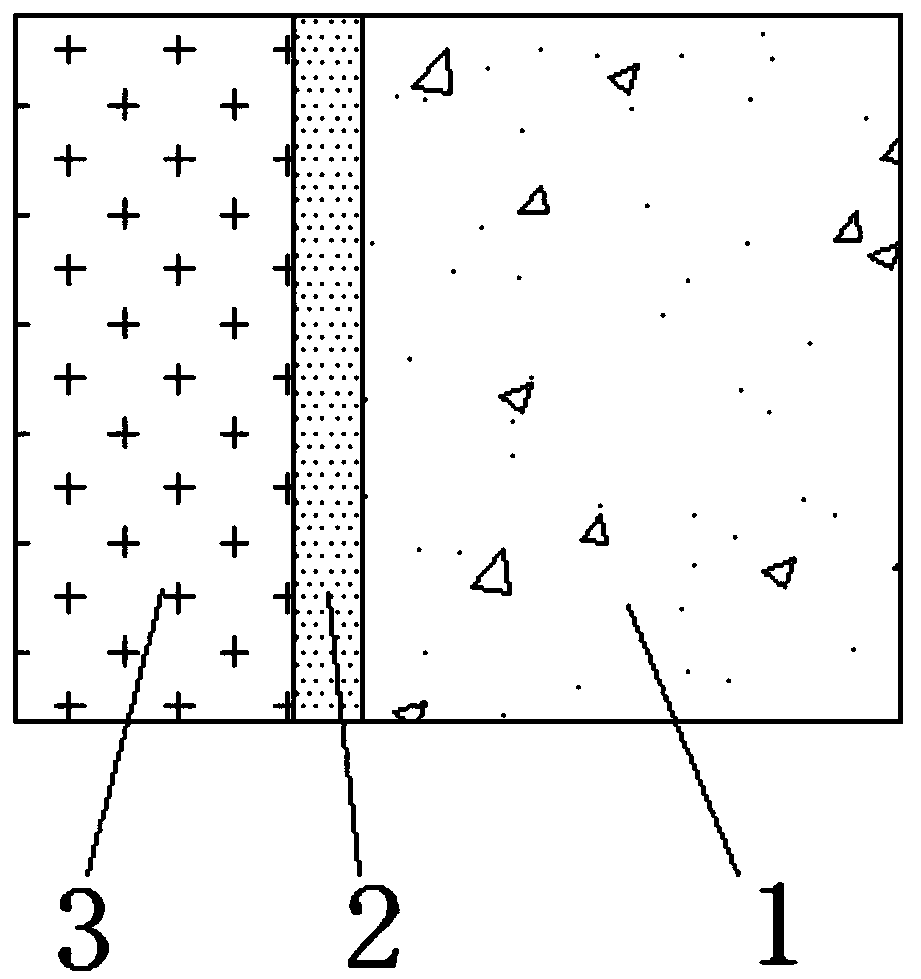

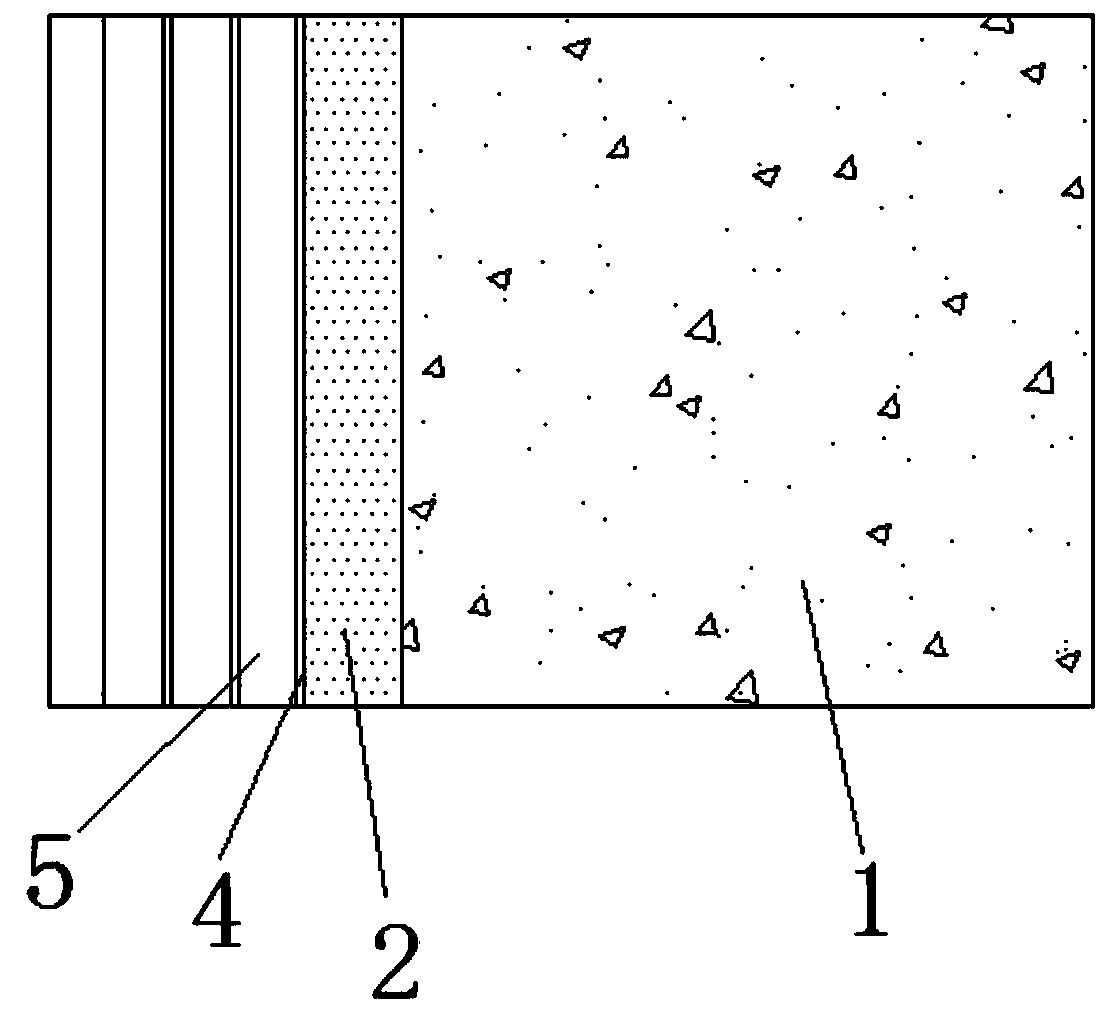

[0037] Such as figure 1 and 2 As shown, a diamond-like coating piston ring includes a piston ring base 1, the outer surface of the piston ring base 1 is provided with a titanium nitride transition layer 2 with increasing nitrogen content, the piston ring base 1 and the titanium nitride transition layer A titanium layer is provided between 2, and the thickness of the titanium layer is less than or equal to 10% of the thickness of the titanium nitride transition layer;

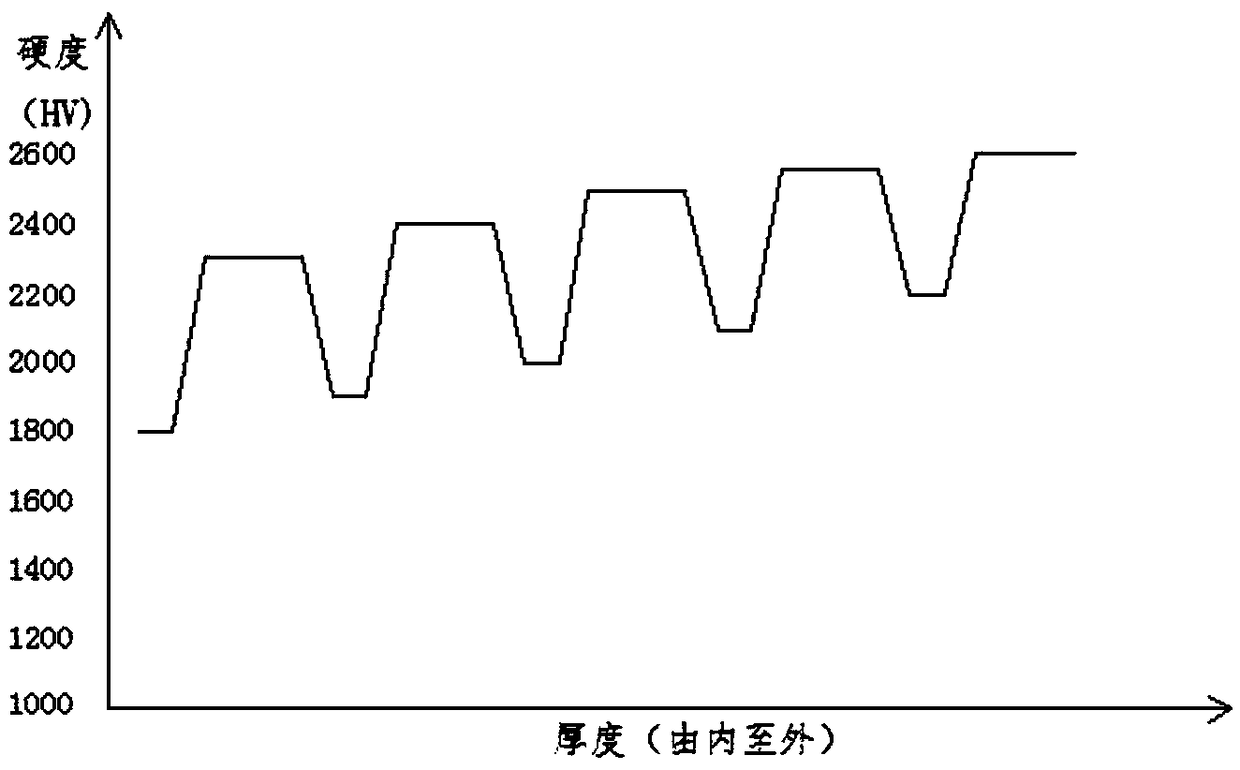

[0038] Preferably, a titanium layer is arranged on the piston ring, and the titanium layer and the piston ring base 1 have a very similar thermal deformation amount, and the content of nitrogen gas is gradually increased while forming titanium nitride, thereby changing the hardness of the titanium nitride, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com