Preparation of transitional metal/nitrogen co-doped hollow carbon nano material and application thereof

A transition metal, hollow carbon sphere technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of difficult to promote commercial applications, low catalytic activity of catalysts, poor long-term stability, etc., and achieve excellent anti-methanol poisoning performance, Simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

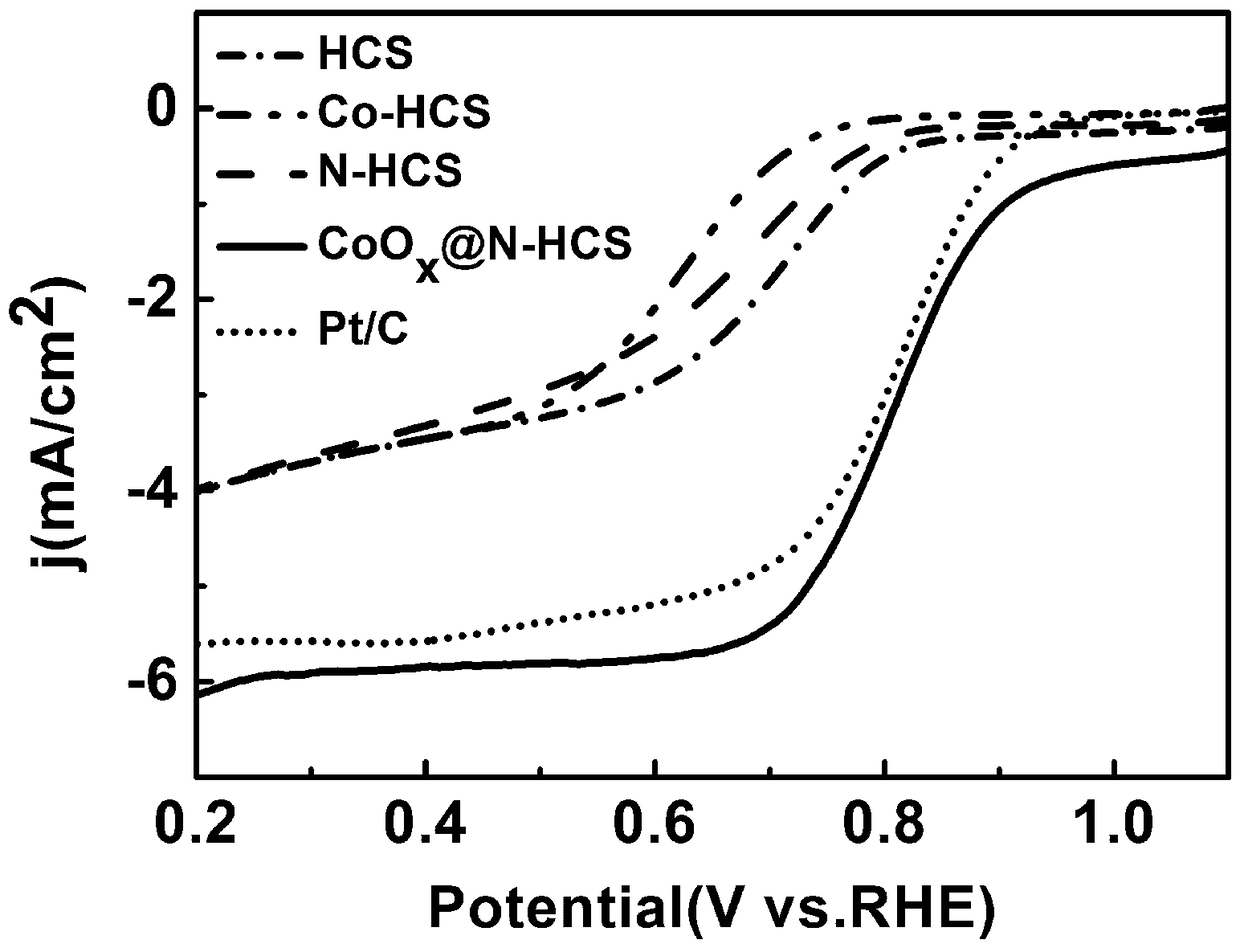

[0017] Example 1: Preparation of hollow carbon sphere-based oxygen reduction catalyst

[0018] Weigh 77 mg of 2,4-dihydroxybenzoic acid and 30 mg of hexamethylenetetramine, dissolve them in 25 mL of deionized water, and stir thoroughly for 10 min to obtain solution A. Weigh 30 mg of the template agent sodium oleate and dissolve it in 4.7 mL of deionized water, add 3.6 mL of Pluronic P123 (5 mg / mL) at the same time, and stir thoroughly for 10 min to obtain solution B. During the stirring process, solution B was added dropwise to solution A, and the stirring was continued for 10 min to obtain solution C. Pour solution C into the reaction kettle to seal it and put it in an oven. Program the temperature to 160°C at a rate of 1°C / min and keep it warm for 2 hours. After the reaction is cooled to room temperature, take out the product and pour it into a centrifuge tube for use. The ultrapure water was centrifuged at 10000 rpm for 10 min, repeated three times, and the obtained precip...

Embodiment 2

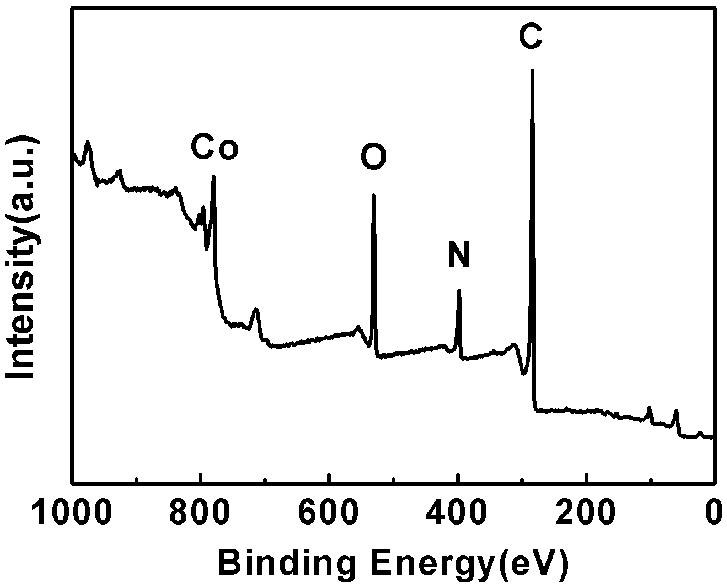

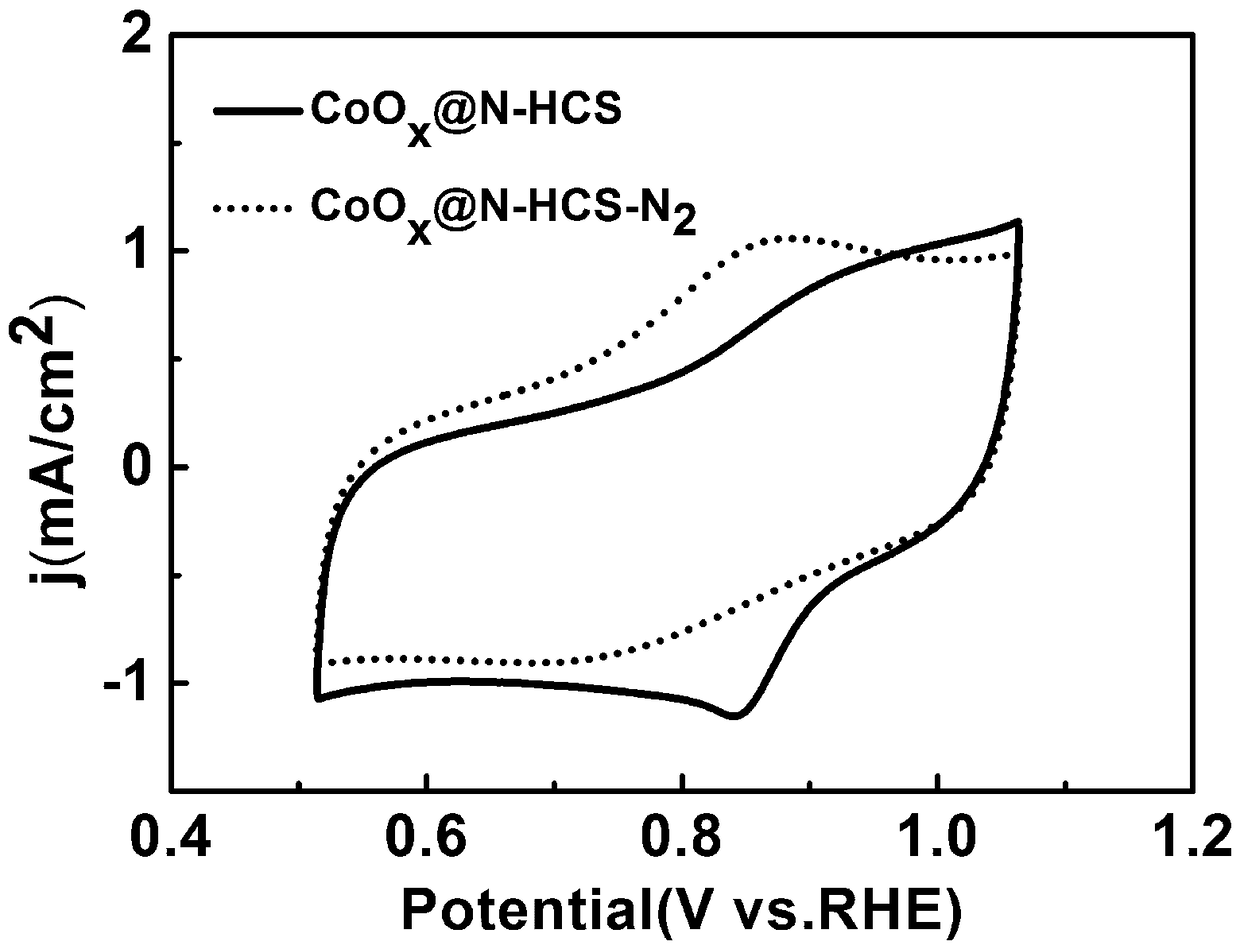

[0019] Example 2: Preparation of transition metal-doped hollow carbon sphere-based oxygen reduction catalyst

[0020] Weigh 77 mg of 2,4-dihydroxybenzoic acid and 30 mg of hexamethylenetetramine, dissolve them in 25 mL of deionized water, and stir thoroughly for 10 min to obtain solution A. Weigh 30 mg of the template agent sodium oleate and dissolve it in 4.7 mL of deionized water, add 3.6 mL of Pluronic P123 (5 mg / mL) at the same time, and stir thoroughly for 10 min to obtain solution B. During the stirring process, solution B was added dropwise to solution A, and the stirring was continued for 10 min to obtain solution C. Pour solution C into the reaction kettle to seal it and put it in an oven. Program the temperature to 160°C at a rate of 1°C / min and keep it warm for 2 hours. After the reaction is cooled to room temperature, take out the product and pour it into a centrifuge tube for use. The ultrapure water was centrifuged at 10000 rpm for 10 min, repeated three times, ...

Embodiment 3

[0021] Example 3: Preparation of nitrogen-doped hollow carbon sphere-based oxygen reduction catalyst

[0022]Weigh 77 mg of 2,4-dihydroxybenzoic acid and 30 mg of hexamethylenetetramine, dissolve them in 25 mL of deionized water, and stir thoroughly for 10 min to obtain solution A. Weigh 30 mg of the template agent sodium oleate and dissolve it in 4.7 mL of deionized water, add 3.6 mL of Pluronic P123 (5 mg / mL) at the same time, and stir thoroughly for 10 min to obtain solution B. During the stirring process, solution B was added dropwise to solution A, and the stirring was continued for 10 min to obtain solution C. Pour solution C into the reaction kettle to seal it and put it in an oven. Program the temperature to 160°C at a rate of 1°C / min and keep it warm for 2 hours. After the reaction is cooled to room temperature, take out the product and pour it into a centrifuge tube for use. The ultrapure water was centrifuged at 10000 rpm for 10 min, repeated three times, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com