High-power slab green laser

A laser and high-power technology, applied in the direction of lasers, laser components, laser components, etc., can solve the problems of reduced beam quality, small pump spot, difficult to apply, etc., to achieve simple structural design, suppress thermal effects, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: A high-power slab green laser that realizes the output of a 545nm green laser

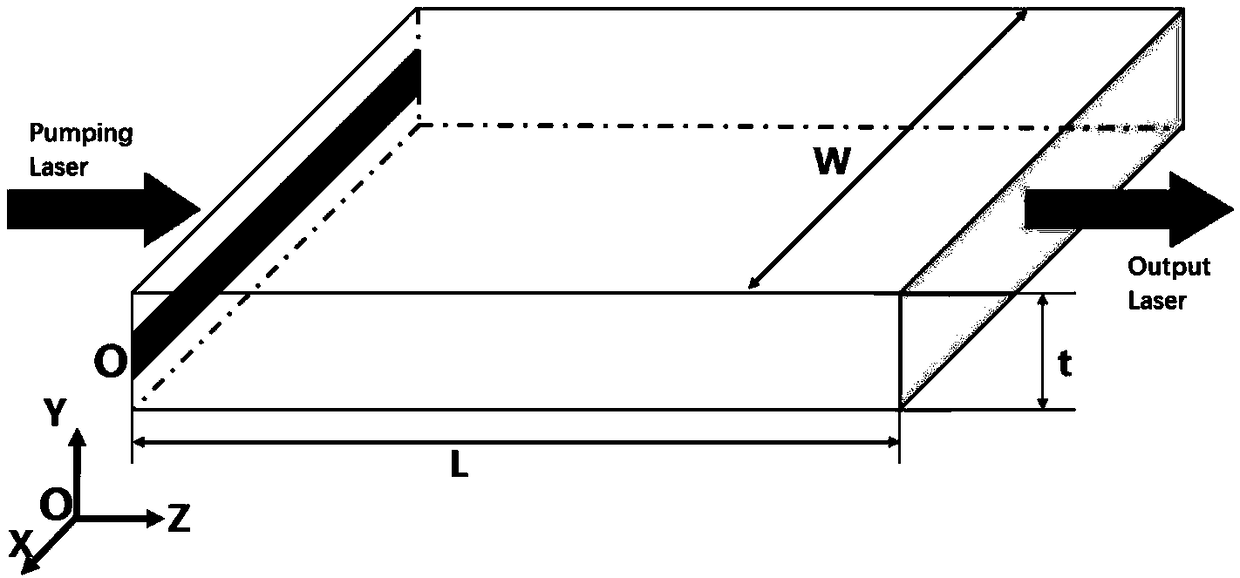

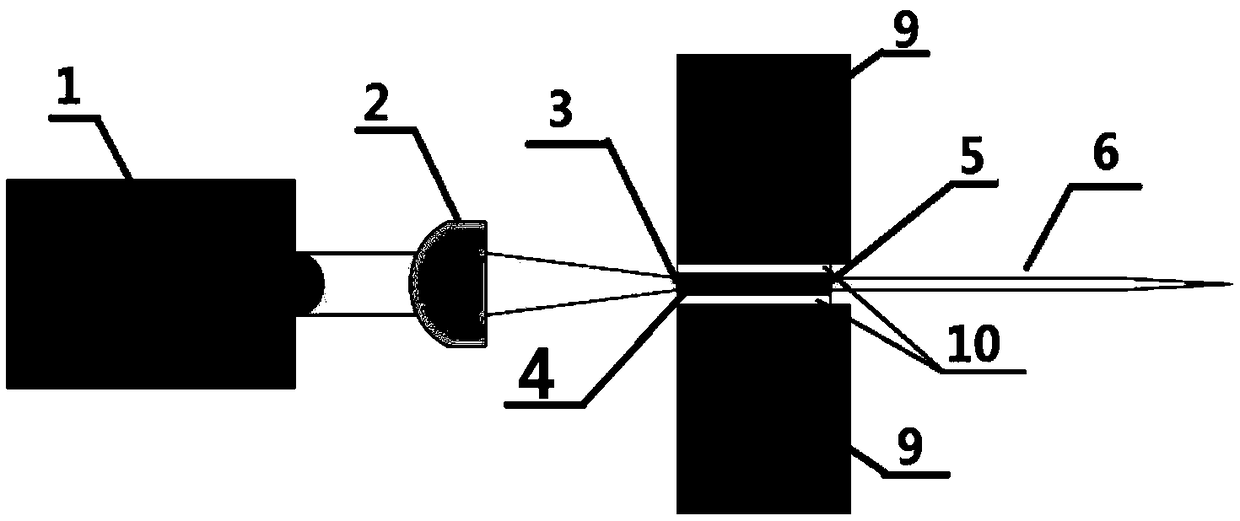

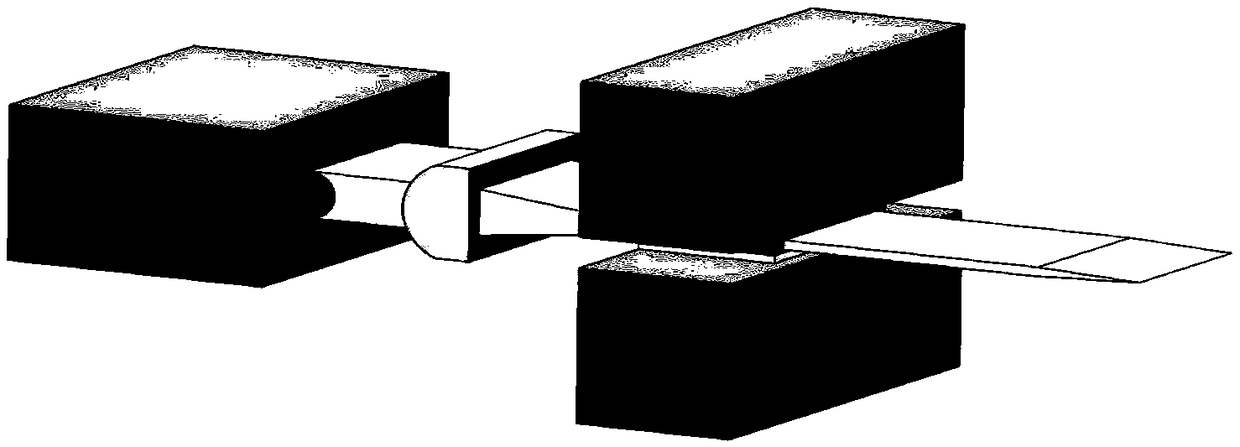

[0064] A high-power slab green laser with a structure such as figure 2 , 3 As shown, the pumping source 1, the focusing system 2, and the self-frequency doubling crystal 4 are sequentially arranged along the optical path. The pump source 1 is a laser diode array with an emission center wavelength of 808nm; the focusing system 2 is composed of a plano-convex cylindrical mirror with a focal length of 6.35cm; the self-frequency doubling crystal 4 is calcium borate with a neodymium ion doping concentration of 8at.% Oxygen gadolinium crystal, the length of the crystal in the light-passing direction is 8mm, and the light-passing surface is 12×1mm 2 Rectangular, and polished, the tangent is cut along the phase matching direction with the largest effective nonlinear coefficient at 1090nm. The best phase matching direction is: the main axis direction (Z axis) with the largest refract...

Embodiment 2

[0067] A high-power slab green laser, as described in Embodiment 1, the difference is that the pump source 1 is a laser diode array with an emission center wavelength of 880nm, and other conditions and components are consistent with those described in Embodiment 1, which can realize 545nm band green laser output. When the laser in this embodiment is used, the quantum defect is small, which is beneficial to the high-efficiency output of the laser.

Embodiment 3-5

[0069] A high-power slab green laser, as described in Embodiment 1, the difference is that the self-frequency doubling crystal 4, the length of the light-transmitting direction of the neodymium ion-doped calcium borate-gadolinium-oxygen crystal is 4mm, 6mm and 10mm respectively, Other conditions and components are consistent with those described in Example 1. Both achieve 545nm band green laser output.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com