Initiating system of polymerization of acrylate monomer photoinduced electron transfer and reversible addition-fragmentation chain transfer

A technology of initiating system and chain transfer agent, which is applied in the field of new photosensitizer and initiating system, can solve the problems of self-quenching of porphyrin excited state, reducing the efficiency of photoredox catalyst, etc., and achieves the simple and easy preparation method and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

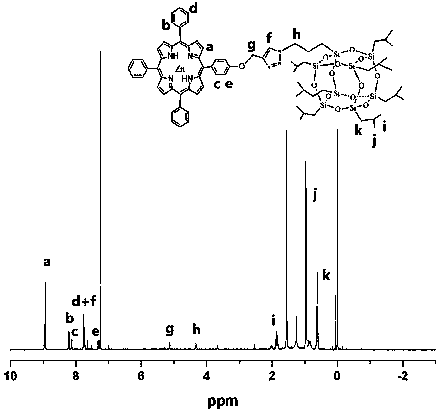

Method used

Image

Examples

Embodiment 1

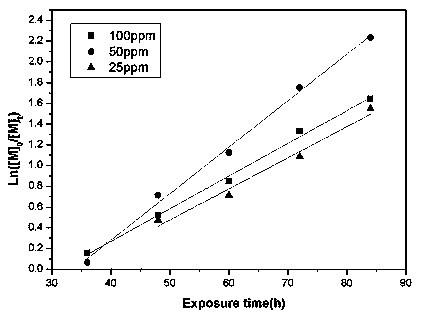

[0026] Example 1, the photopolymerization of MMA monomer under the zinc porphyrin-POSS / CDB initiation system (catalyst concentration 100 ppm)

[0027] The volume fraction of 2 mL monomeric MMA in dimethyl sulfoxide (DMSO) solvent (2 mL) was 50 %. According to the molar ratio [MMA]: [CDB]: [Zinc porphyrin-POSS] = 200: 1: 0.02, the above raw materials were respectively added into 12 mL single-branched glass bottles. Seal with a rubber stopper. Oxygen was removed by bubbling, nitrogen gas was passed in with a fine needle, and the other needle was used to vent gas. This continued for half an hour, so that the polymerization reaction was carried out under the irradiation of a 10 W green light strip in a nitrogen atmosphere. The specific reaction device is shown in Figure 1. At different time intervals, a small amount of samples were taken from the reaction system with a syringe, and the samples were used for nuclear magnetic testing to calculate the conversion rate. The sample w...

Embodiment 2

[0033] Example 2, the photopolymerization of MMA monomer under the zinc porphyrin-POSS / CDB initiation system (catalyst concentration 50 ppm)

[0034] Referring to Example 1, the photopolymerization of the MMA monomer under the zinc porphyrin-POSS / CDB initiation system was carried out. MMA monomer was 2 mL, and the molar ratio of [MMA]:[CDB]:[Zinc porphyrin-POSS] was 200:1:0.01. Samples taken at different time periods were precipitated with methanol three times, dried in vacuum to constant weight, and a light red substance was obtained. At 48 h, the monomer conversion rate was 51.02%, and the polymerization product M was measured by GPC n = 9800, PDI = 1.12. In addition, during the polymerization process, the molecular weight of the polymer increases linearly with the increase of the conversion rate, and the molecular weight distribution of the polymer is narrow (less than 1.3), which conforms to the law of living polymerization. After 48 h of light exposure time, the power...

Embodiment 3

[0037] Example 3, the photopolymerization of MMA monomer under the zinc porphyrin-POSS / CDB initiation system (catalyst concentration 25 ppm)

[0038] Referring to Example 1, the photopolymerization of the MMA monomer under the zinc porphyrin-POSS / CDB initiation system was carried out. Take 2 mL of monomeric MMA with a volume fraction of 50% monomer in dimethyl sulfoxide (DMSO) solvent (2 mL). Wherein the molar ratio of [MMA]:[CDB]:[zinc porphyrin-POSS] is 200:1:0.005. Samples taken at different time periods were precipitated with methanol three times, dried in vacuum to constant weight, and a light red substance was obtained. At 48 h, the monomer conversion rate was 34.25%, and the polymer product M was measured by GPC n = 7700, PDI = 1.15. In addition, during the polymerization process, the molecular weight of the polymer increases linearly with the increase of the conversion rate, and the molecular weight distribution of the polymer is narrow (less than 1.3), which confo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com