A kind of organic carrier for front silver paste and preparation method thereof

A technology of organic carrier and silver paste, applied in the direction of semiconductor devices, conductive materials dispersed in non-conductive inorganic materials, electrical components, etc., can solve the problems of poor line aspect ratio, complex system, poor printing characteristics, etc., to achieve Improved adhesion, simple ingredients, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] An organic carrier for positive silver paste, composed of the following raw materials in weight percentage: diethylene glycol octyl ether 32%, tripropylene glycol methyl ether 20.4%, butyl carbitol acetate 17%, and triglyceride modified Silicone resin 23.4%, rosin modified acrylic resin 1.2%, BYK-110 dispersant 3%, BYK-111 dispersant 3%, the preparation process of the organic carrier includes the following steps:

[0016] (1) Weigh the raw material of the organic carrier according to the above weight percentage, and then place it in a stainless steel heating kettle with a high-speed shear mixing head after the weighing;

[0017] (2) Seal the heating kettle, start the high-speed shear mixing head in the stainless steel heating kettle, and make the shear rate 20000r / min; at the same time, start the heating button, and heat the organic mixture to 90 at a heating rate of 2℃ / min. Within the range of ±5℃, and heat preservation for 2h;

[0018] (3) Turn off the high-speed shear mixi...

Embodiment 2

[0026] An organic carrier for positive silver paste, which is composed of the following raw materials in weight percentage: diethylene glycol octyl ether 30.7%, tripropylene glycol methyl ether 22.4%, butyl carbitol acetate 15%, and triglyceride modified The organic silicon resin is 24%, the rosin-modified acrylic resin is 1.5%, the BYK-110 dispersant is 3.2%, and the BYK-111 dispersant is 3.2%. The preparation process of the organic carrier is the same as that of Example 1.

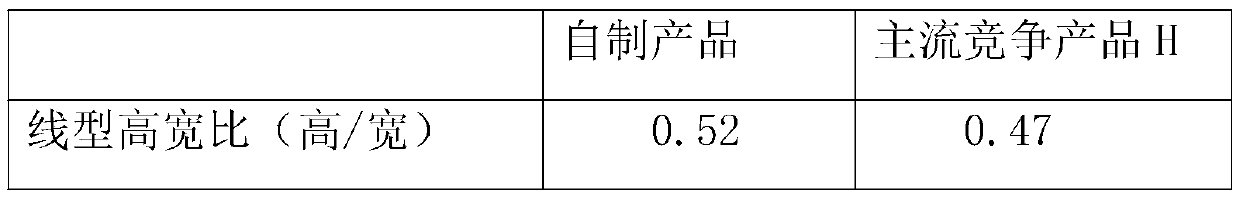

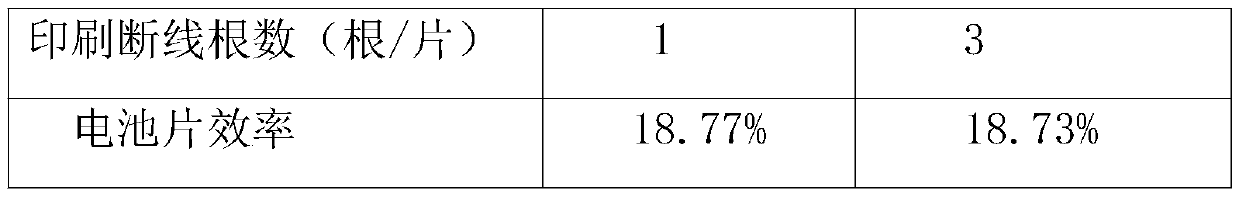

[0027] The finished carrier will be prepared according to the preparation process of the organic carrier, and then 8.3% organic carrier, 2.1% glass powder, and 89.6% silver powder will be used to prepare the finished paste, and then print, sinter and test the terminal performance according to the application process of the paste. The final data As shown in the following table:

[0028] Homemade products Mainstream competitive product H Linear aspect ratio (height / width)0.550.47 Number of broken lines (p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com