Production method of tobacco liposome modified by polyethylene glycol-poly(beta-amino ester)

A polyethylene glycol modification and polyethylene glycol technology, which is applied in liposome delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve liposome loading capacity, stability, and embedding rate And the degradability rate needs to be improved to achieve good biocompatibility, improve stability, and increase the effect of grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

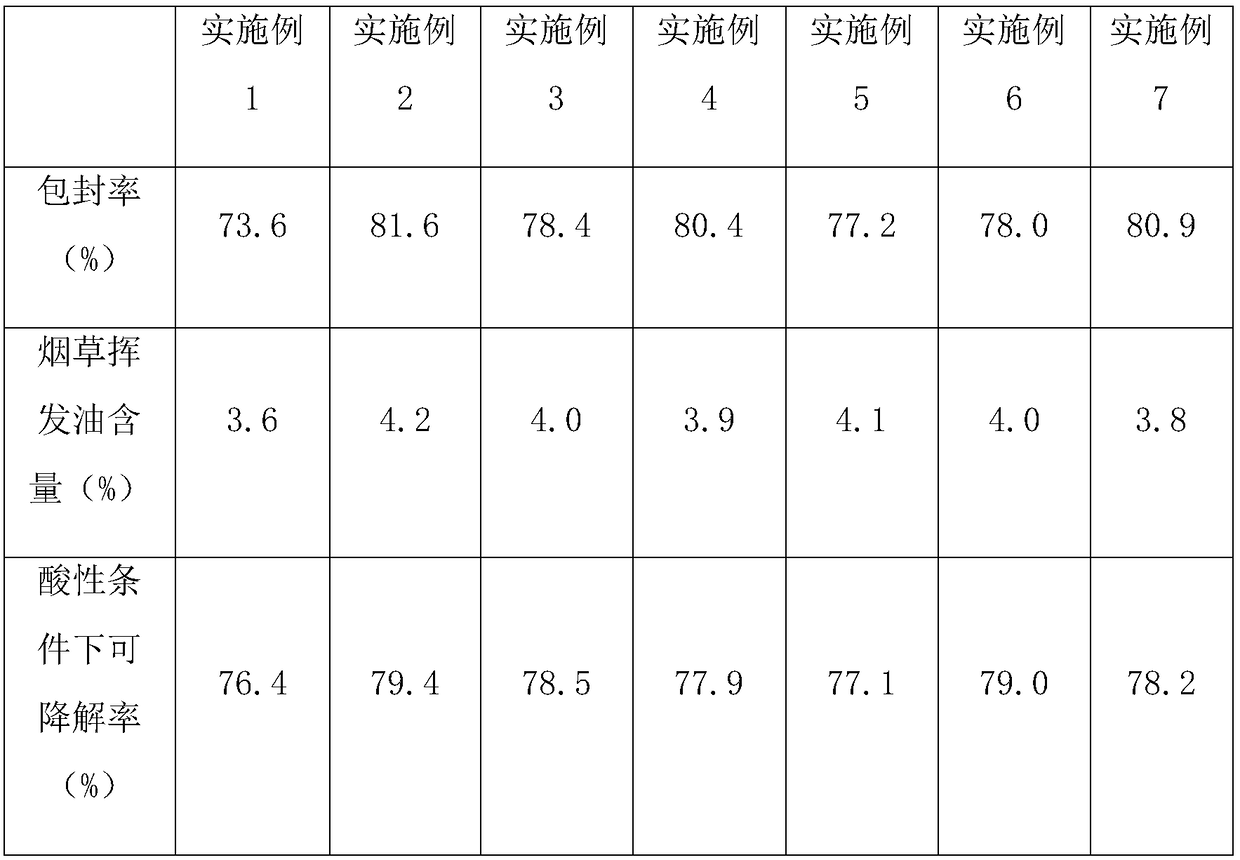

Examples

Embodiment 1

[0024] (1) Add methoxypolyethylene glycol with a molecular weight of 1500 into tetrahydrofuran, stir at 0°C until dissolved, and add propylene dropwise according to the molar ratio of methoxypolyethylene glycol and acryloyl chloride to 1:2 Acryloyl chloride, heated and reacted at 25°C for 12h, filtered, and freeze-dried to obtain acryloyl chloride-modified polyethylene glycol.

[0025] (2) Add tobacco volatile oil, phospholipid and cholesterol with a molar ratio of 2.5:1 to ethanol, mix evenly, transfer to a supercritical carbon dioxide fluid reactor, and replace ethanol with carbon dioxide. The molar ratio to cholesterol is 0.4:1, add acryloyl chloride modified polyethylene glycol, add phosphoric acid to adjust the pH value of the system to 7.2, stir and disperse evenly, heat up to 40°C at a rate of 5°C / min, and under 15MPa, Stir at a rate of 100r / min for 15min, then raise the temperature to 58°C at a rate of 1°C / min, and stir at a rate of 500r / min for 30min at 28MPa until su...

Embodiment 2

[0028] (1) Add methoxypolyethylene glycol with a molecular weight of 2500 into tetrahydrofuran, stir at 4°C until dissolved, and add propylene dropwise according to the molar ratio of methoxypolyethylene glycol and acryloyl chloride to 1:4 Acryloyl chloride, heated and reacted at 30°C for 24h, filtered, and freeze-dried to obtain acryloyl chloride-modified polyethylene glycol.

[0029] (2) Add tobacco volatile oil, phospholipid and cholesterol with a molar ratio of 5:3:1 to ethanol, mix evenly, transfer to a supercritical carbon dioxide fluid reactor, and replace ethanol with carbon dioxide. The molar ratio of diol to cholesterol is 0.7:1, add polyethylene glycol modified by acryloyl chloride, add phosphoric acid to adjust the pH value of the system to 7.4, stir and disperse evenly, and heat up to 45°C at a rate of 10°C / min. Stir at a rate of 200r / min for 20min, then raise the temperature to 65°C at a rate of 3°C / min, and stir at a rate of 800r / min for 90min at 35MPa until sup...

Embodiment 3

[0032](1) Add methoxypolyethylene glycol with a molecular weight of 2000 into tetrahydrofuran, stir at 2°C until dissolved, and add propylene dropwise according to the molar ratio of methoxypolyethylene glycol and acryloyl chloride to 1:2.5 Acyl chloride, heated at 29°C for 16h, filtered, and freeze-dried to obtain acryloyl chloride-modified polyethylene glycol.

[0033] (2) Add tobacco volatile oil, phospholipid, and cholesterol with a molar ratio of 3.5:3:1 to ethanol, mix evenly, transfer to a supercritical carbon dioxide fluid reaction kettle, and replace ethanol with carbon dioxide. The molar ratio of diol to cholesterol is 0.6:1, add polyethylene glycol modified by acryloyl chloride, add phosphoric acid to adjust the pH value of the system to 7.3, stir and disperse evenly, and heat up to 42°C at a rate of 7°C / min. Stir at a rate of 130r / min for 19min, then raise the temperature to 62°C at a rate of 1.5°C / min, and stir at a rate of 600r / min for 45min at 32MPa until superc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com