Clostridium septicum alpha toxin genetic engineering vaccine and production method thereof

A genetically engineered vaccine, the technology of Clostridium putrefaciens, which is applied in the field of Clostridium putrefactive alpha toxin genetically engineered vaccines, can solve the problems of loss of cytotoxicity and unverified antigenicity of recombinant toxins, etc., and achieve the effect of reducing biosafety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

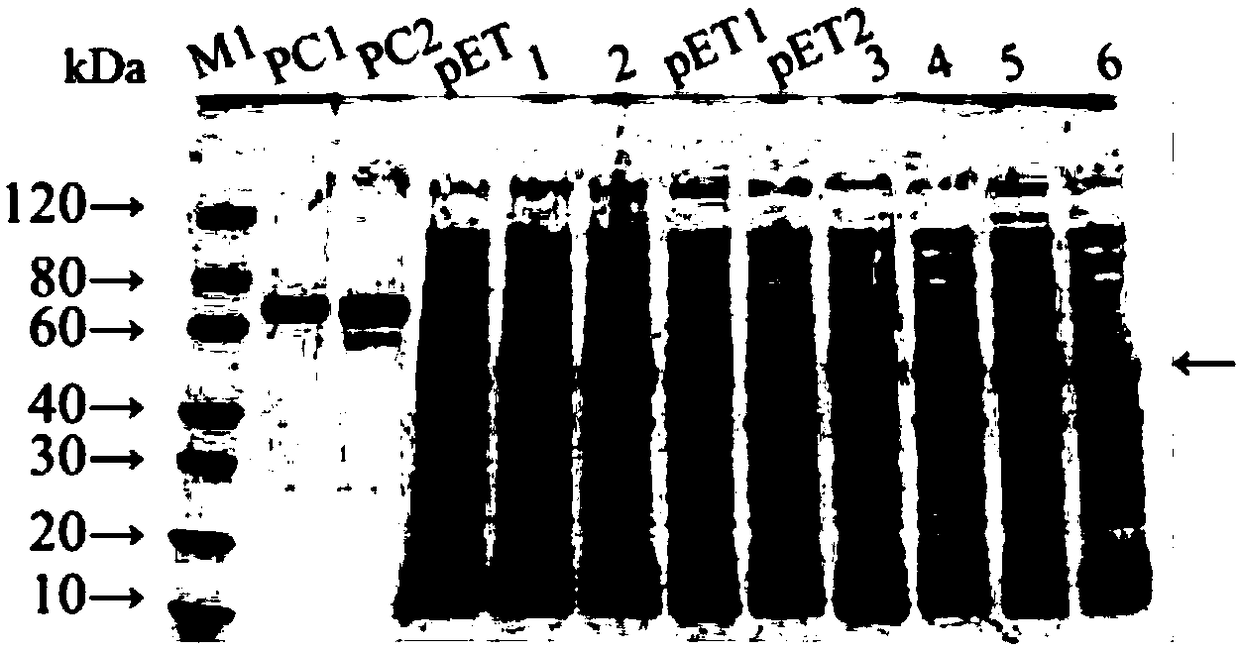

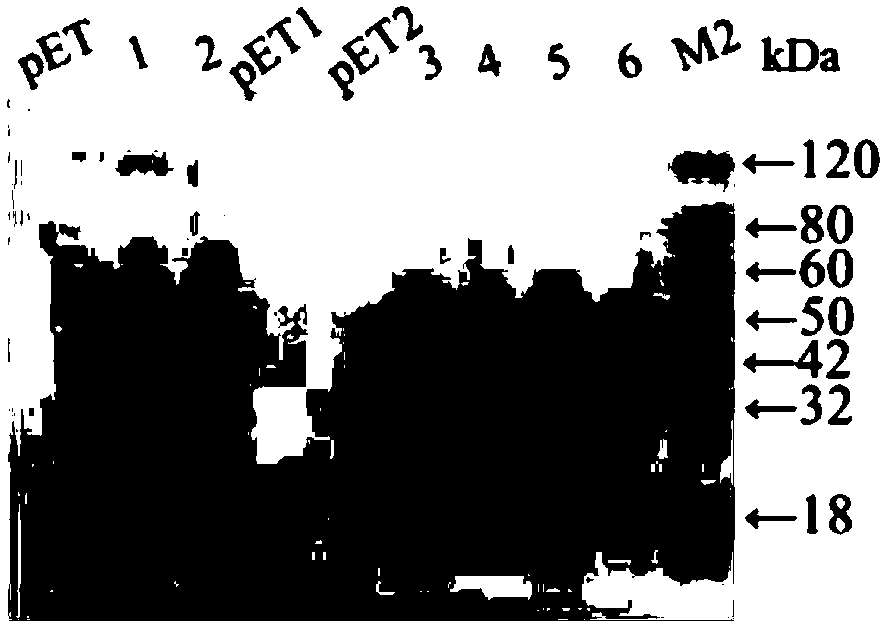

[0046] ——CSA mutants containing both 4 amino acid mutations and 11 amino acid deletions (rCSA M4Δ11 ) construction, expression and identification of expression vector

[0047] 1. Gene synthesis

[0048] According to the gene sequence of natural CSA, the applicant designed 4 amino acid mutations (C54L, N264A, H269A and W310A) and 11 amino acid deletions (positions 212-222) after codon optimization, thereby obtaining the avirulent rCSA M4Δ11 . At the same time, 6 histidine tags were added to the C-terminus of the recombinant protein. The gene sequence was synthesized by chemical synthesis method, which contains 1221 nucleotides in total. Among them, positions 1-1200 are CSA mature toxin sequences (including 4 amino acid mutations and 11 amino acid deletions), and positions 1201-1218 are 6 histidine tag sequences. The specific nucleic acid sequence is shown in SEQ ID No.1, and the amino acid sequence is shown in SEQ ID No.2.

[0049]

[0050]

[0051]

[0052] 2. C...

Embodiment 2

[0067] ——rCSA M4Δ11 Toxicity test on mice

[0068] rCSA M4Δ11 Toxicity to mice to verify the actual attenuation effect of the mutant in animals. rCSA M4Δ11 As well as recombinant CSA (rCSA) without amino acid mutation, 16-18g mice were inoculated through the tail vein at different doses, 5 mice per dose, 0.2mL / mouse. Results When the inoculation dose was 0.1mg, all the mice were healthy and had no adverse reaction, while rCSA inoculation of 46.88ng could cause the death of 5 / 5 mice. The results indicated that rCSA M4Δ11 It is avirulent in mice and was identified as an avirulent mutant of CSA.

[0069] Table 1 rCSA M4Δ11 Toxicity to mice

[0070]

Embodiment 3

[0072] ——rCSA M4Δ11 immunogenicity test

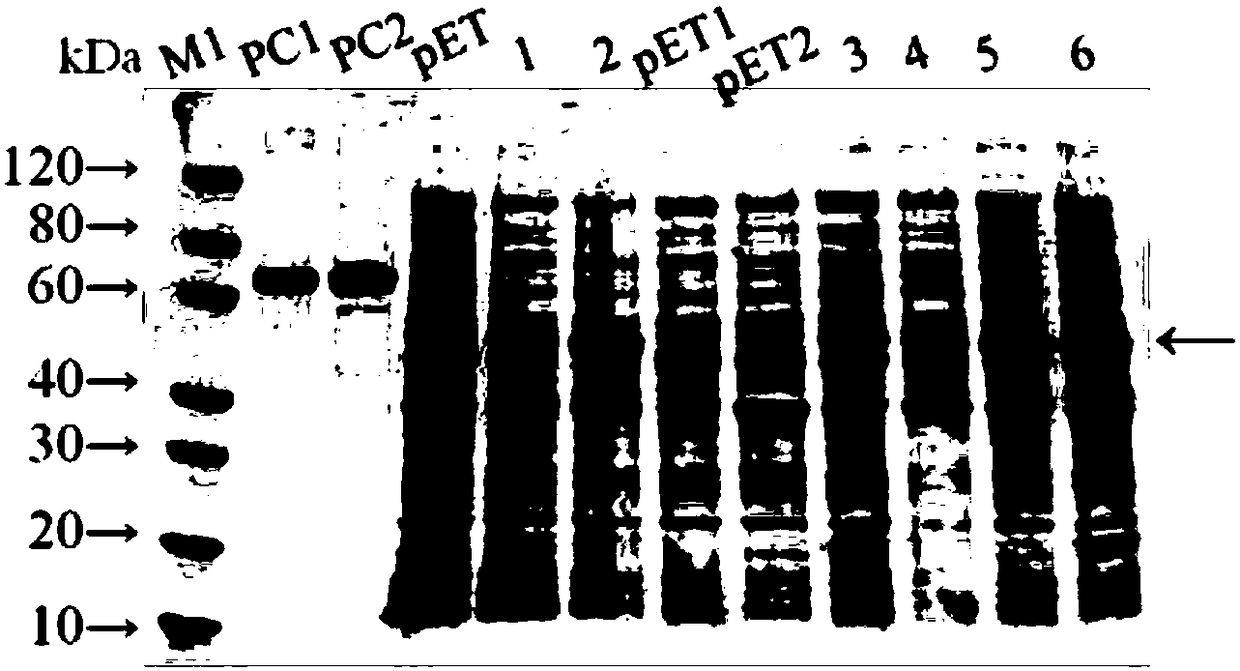

[0073] (1) Bacteria culture: the recombinant expression rCSA M4Δ11 Escherichia coli BLc1 strain culture liquid, inoculated with LB liquid medium containing kanamycin according to 2% of the total amount of the culture medium, and cultured in a fermenter. The culture parameters were set as follows: culture temperature 37°C, pH value 7.0, dissolved oxygen 40%. when culture OD 600 When the value is 10-15, add IPTG with a final concentration of 0.5mmol / L to induce culture for 4h.

[0074] (2) Bacterial destruction: collect the bacteria by centrifugation, add 10mL of lysate (pH value 7.2, 0.02mol / L Tris buffer, 0.3mol / L NaCl) to resuspend the bacteria according to the wet weight of each gram of the bacteria, and resuspend the bacteria at 4°C. Under the condition of low temperature and high pressure homogenizer with the pressure of 800bar, the bacterium was broken 3 times. The lysate was centrifuged at 10,000 r / min at 4°C for 30 min, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com