Non-toxic clostridium perfringens beta-toxin genetic engineering vaccine and production method thereof

A technology of Clostridium perfringens and genetic engineering vaccine, which is applied in the fields of genetic engineering, biochemical equipment and methods, plant gene improvement, etc., can solve the problems affecting the expression level of fusion protein and the reduction of effective antigenic components of fusion protein, and achieves Avoid the effect of immunogenicity of antigenic protein, reduce preparation time and production cost, avoid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] ——Construction, expression and identification of Escherichia coli BL / SUB strain

[0077] 1. Gene synthesis

[0078] According to the sequence of the natural protein gene of Clostridium perfringens β toxin, the application designed 4 amino acid mutations after codon optimization, and the 212th arginine in the mature toxin of the wild type Clostridium perfringens β toxin Acid is mutated to glutamic acid, leucine at position 268 is mutated to glycine, tyrosine at position 266 and tryptophan at position 278 are mutated to alanine, thus obtaining a beta toxin mutant that is non-toxic to animals . At the same time, a SUMO tag and a 6×His tag were added to the N-terminal and C-terminal, respectively. The gene sequence GSUMO-CPB was synthesized by chemical synthesis m4 , containing a total of 1296 nucleotides. The specific nucleic acid sequence is shown in SEQ ID No.1, and the amino acid sequence is shown in SEQ ID No.2.

[0079] 2. Construction of fusion expression vector...

Embodiment 2

[0090] - Expression and identification of target genes

[0091] 1. Expression of target protein

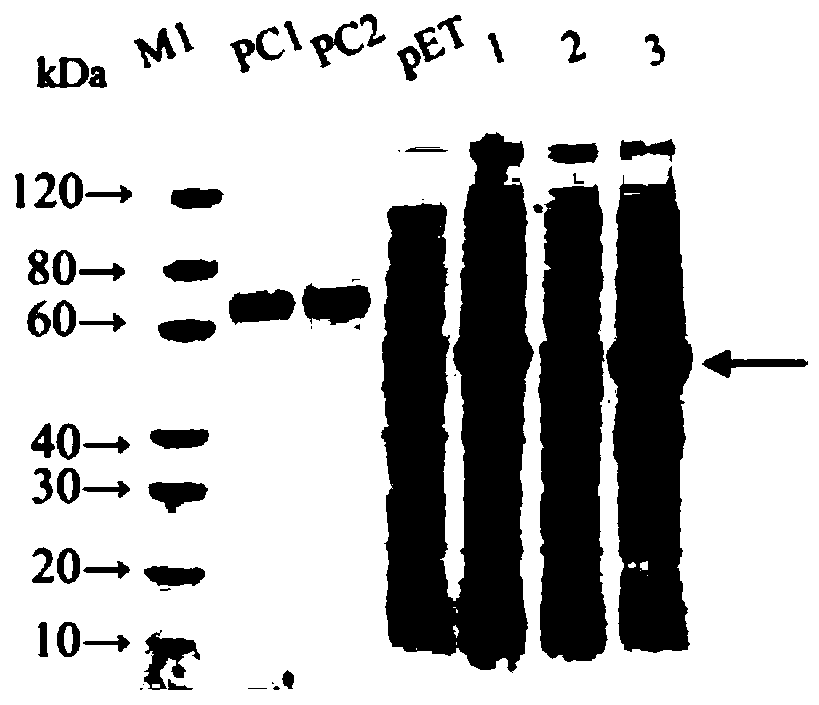

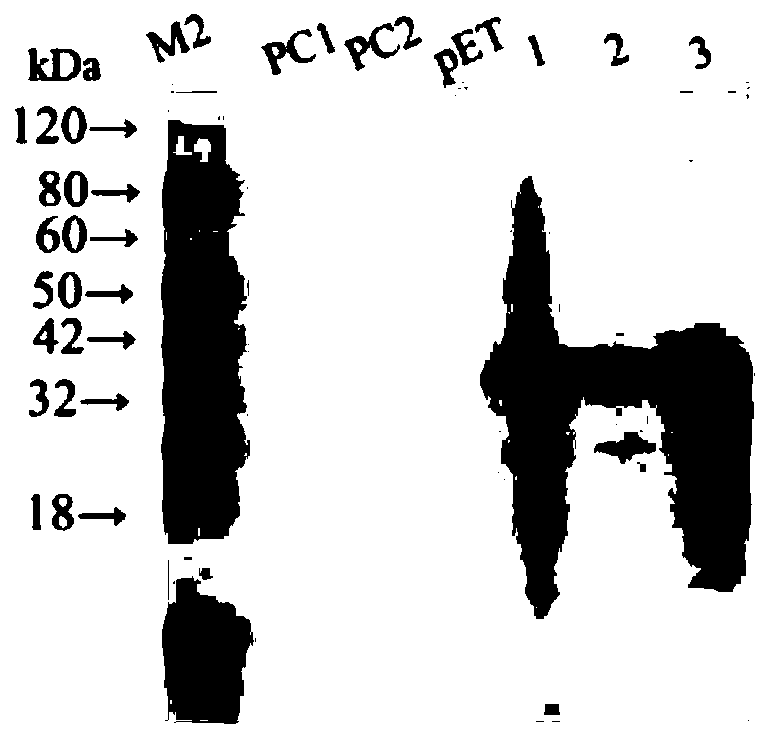

[0092] Inoculate the recombinant Escherichia coli (E.coli) BL / SUB strain in 4 mL of LB liquid medium containing kanamycin, and shake at 37°C for OD 600 When the temperature is 0.6-0.8, lower the temperature to 15°C, and add IPTG solution with a final concentration of 0.5mmol / L to induce culture for 16h. After the bacterial culture was completed, the bacterial cells were collected by centrifugation, and the bacterial cells were resuspended at a ratio of 10 mL of lysate [0.02 mol / L Tris buffer (pH 7.2), 0.3 mol / L NaCl] per gram of bacterial body weight, and placed in an ice-water bath. The bacteria were disrupted by ultrasonic for 30 minutes, the crushing conditions were: working for 9s, resting for 9s, and the ultrasonic power was 400W. The crushed bacterial liquid was centrifuged at 12000r / min for 10min at 4°C, and the supernatant was collected. Take 30 μL of the supernatant an...

Embodiment 3

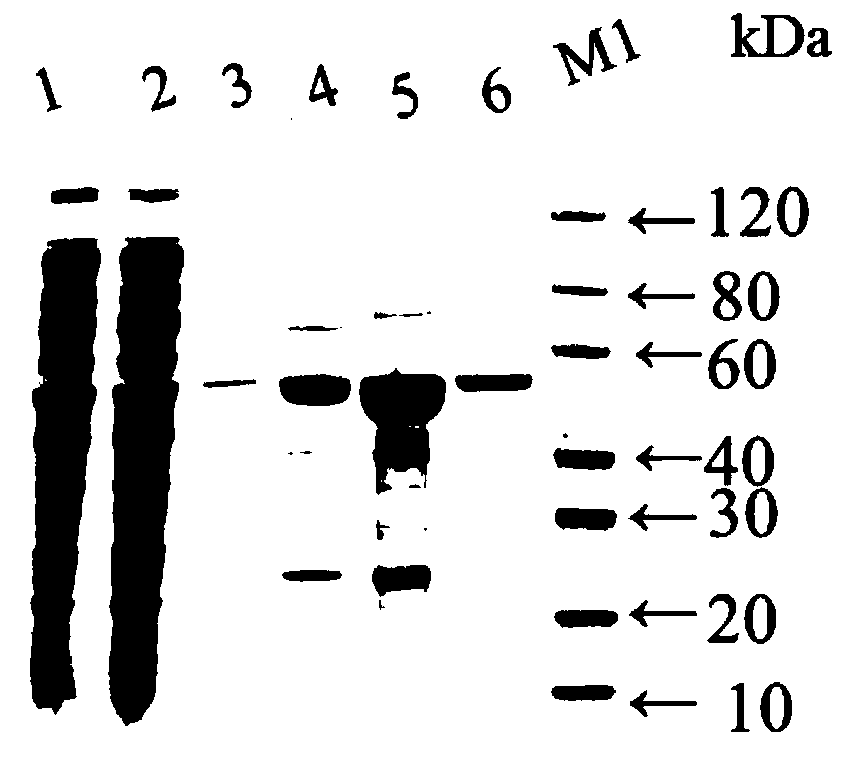

[0096] ——rSUMO-CPB m4 purification of

[0097] Inoculate the recombinant Escherichia coli (E.coli) BL / SUB strain in 1L LB liquid medium containing kanamycin for fermentation culture, shake culture at 37°C OD 600 When the temperature is 0.6-0.8, lower the temperature to 15°C, and add IPTG solution with a final concentration of 0.5mM to induce culture for 16h. After the bacterial culture was completed, the bacterial cells were collected by centrifugation, and the supernatant was collected according to the method in step 4. From the supernatant collected in the above step 4, purify the soluble expressed target protein in the cell lysate supernatant according to the instruction manual of the Ni-IDA affinity chromatography medium kit, and filter it through a 0.22 μm pore size filter membrane to obtain Primary purified target protein rSUMO-CPB m4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com