Efficient sewage purifying biological filter device and using method

A technology of biological filter and sewage treatment tank, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problem of not being able to meet the requirements for environmental protection of treated water and receiving water bodies, and the inability to achieve simultaneous removal of pollutants efficiency, inability to meet the overall requirements of sewage treatment, etc., to achieve the effect of helping growth and enrichment, reducing backwash costs, and low construction and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

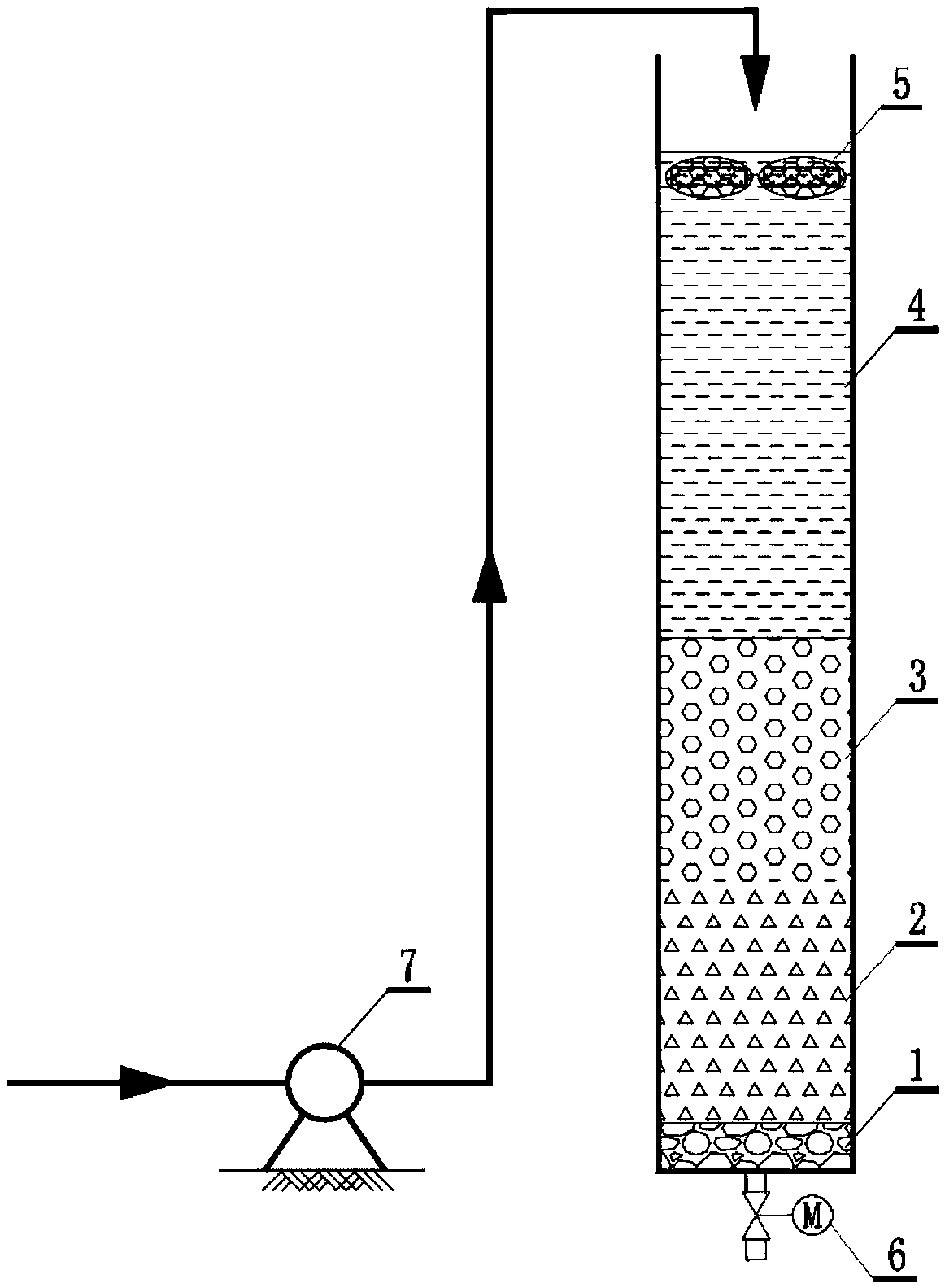

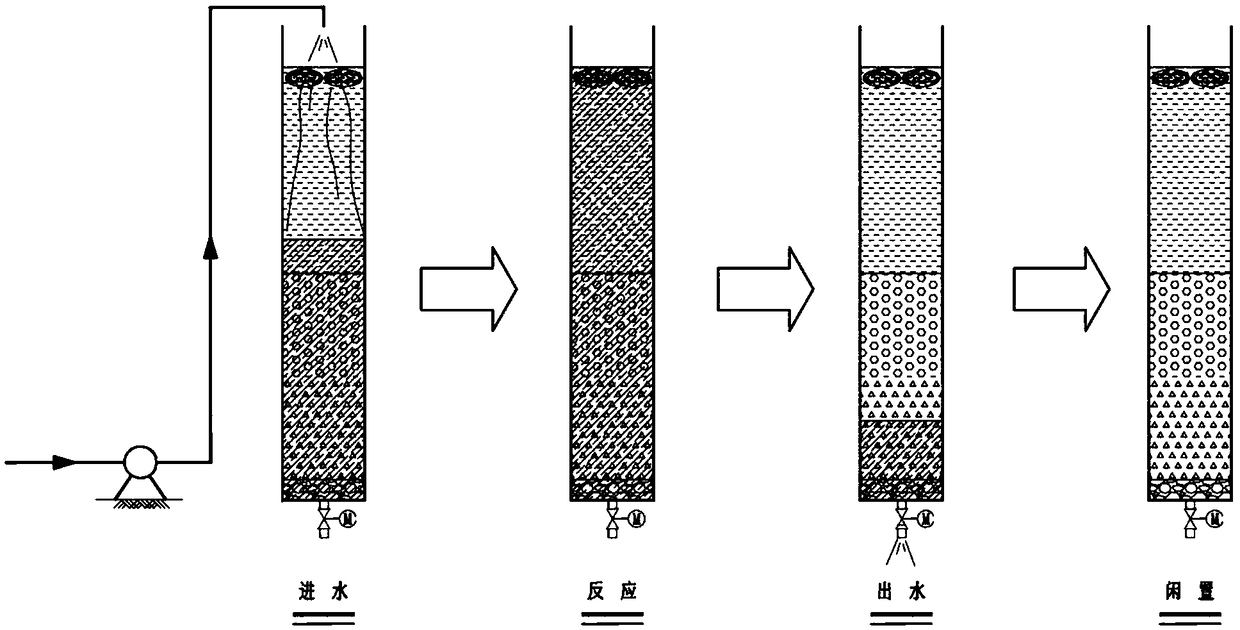

[0037] (1) A cylindrical PE material filter tank with a height of 1.1m and a diameter of 0.1m, with a 5cm thick gravel layer at the bottom. It is filled with volcanic rock at a filling height of 0.25m; the top is filled with ceramsite at a filling height of 0.25m; the particle size range of volcanic rock and ceramsite is 5-8cm. The fiber silk material is placed on the upper layer, and the stacking height is 0.5m. 100g wooden sticks are put into 2 nylon mesh bags and dropped into the filter tank.

[0038] (2) The filter operates in a tidal manner. The influent water is heavily polluted urban river water after preliminary sedimentation treatment, its COD is 58mg / L, ammonia nitrogen is 7mg / L, nitrate nitrogen is 13mg / L, and total phosphorus is 1mg / L. The device can hold 4.0L of water. After the water inlet pump is turned on for 5 minutes, the filter tank is filled with sewage, and the water inlet pump is turned off. The device continued to treat for 16 hours under the conditi...

Embodiment 2

[0041] (1) A cylindrical PE material filter tank with a height of 1.1m and a diameter of 0.1m, with a 5cm thick gravel layer at the bottom. It is filled with volcanic rock at a filling height of 0.25m; above it is filled with zeolite at a filling height of 0.25m; the particle size of volcanic rock and zeolite is 5-8cm. The fiber silk material is placed on the upper layer, and the stacking height is 0.5m. 150g wooden sticks are put into 2 nylon mesh bags and dropped into the filter tank.

[0042] (2) The filter is operated in a tidal manner, and the influent is the tail water of a sewage treatment plant. Its COD is 45mg / L, ammonia nitrogen is 2.5mg / L, nitrate nitrogen is 12.5mg / L, and total phosphorus is 0.45mg / L. After the water inlet pump is turned on for 5 minutes, the filter tank is filled with sewage, and the water inlet pump is turned off. After the device is saturated, the treatment continues for 12 hours, then the water outlet valve is opened for 5 minutes, and the de...

Embodiment 3

[0044] (1) A cylindrical PE material filter tank with a height of 1.1m and a diameter of 0.2m, with a 5cm thick gravel layer at the bottom. It is filled with volcanic rock at a filling height of 0.25m; the top is filled with ceramsite at a filling height of 0.25m; the particle size of volcanic rock and ceramsite is 5-8cm. The fiber silk material is placed on the upper layer, and the stacking height is 0.5m.

[0045] (2) The filter operates in a tidal manner. The influent is rural domestic sewage after primary treatment, its COD is 180mg / L, ammonia nitrogen is 24mg / L, nitrate nitrogen is 2mg / L, and total phosphorus is 1.8mg / L. After the water inlet pump is turned on for 8 minutes, the filter tank is filled with sewage, and the water inlet pump is turned off. After the device is saturated, the treatment continues for 8 hours, and then the outlet valve is opened for 8 minutes. After the treated water is discharged, the device is left empty for 12 hours. The cycle is repeated. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com