Hot melt butyl adhesive with high cohesion strength and preparation method of hot melt butyl adhesive

A hot-melt butyl adhesive, cohesive strength technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of low peel strength between the self-adhesive surface and the adhered surface, and limited Problems such as the popularization and use of base pressure-sensitive adhesives and high requirements for material technical indicators can achieve the effects of high cohesive strength, changing hot-melt fluidity, and good hot-melt fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

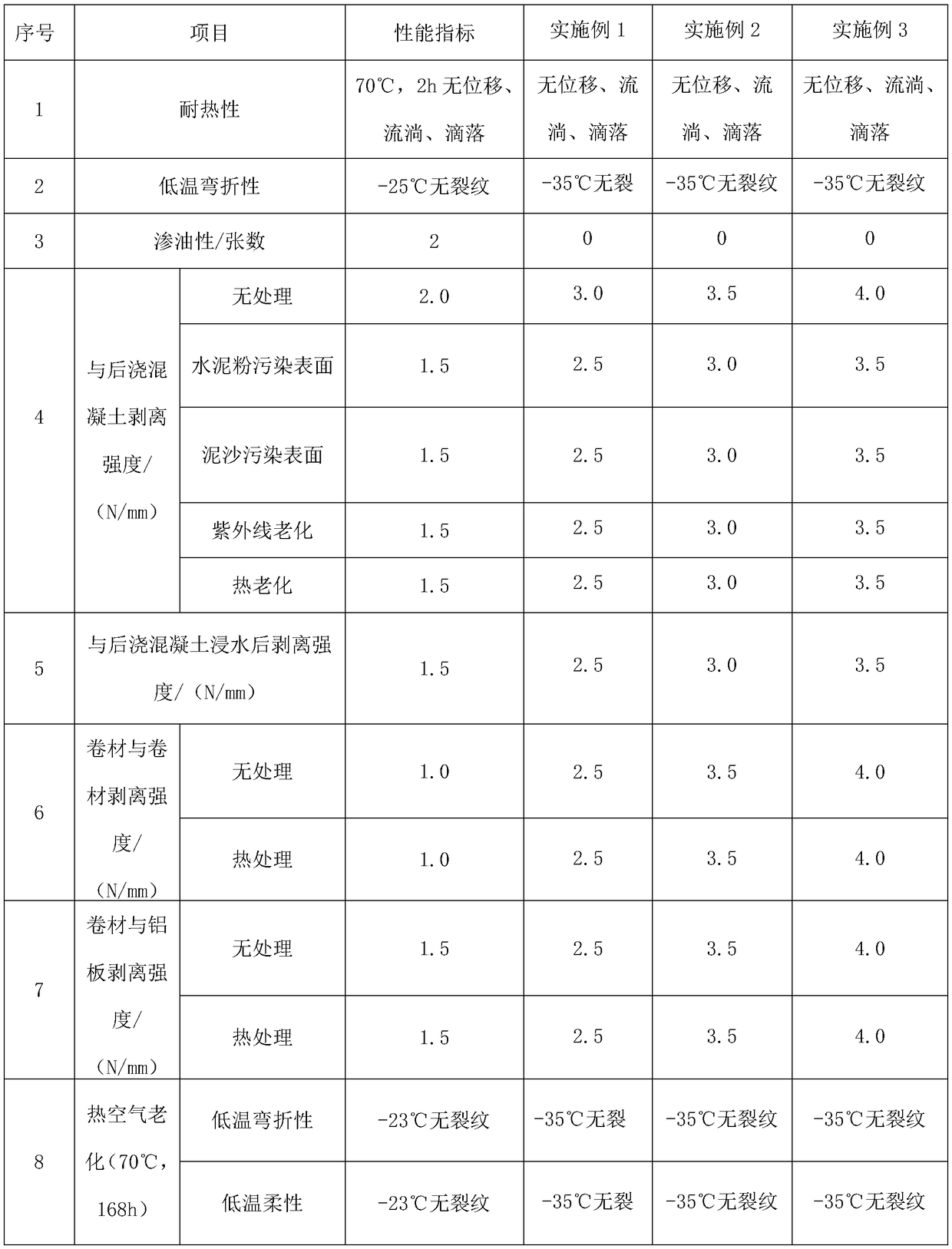

Examples

Embodiment 1

[0037] This embodiment provides a high cohesive strength hot-melt butyl rubber, including the following raw material components in parts by weight: 20 parts of butyl rubber, 10 parts of hot-melt reinforcing agent, 1 part of flux, and 25 parts of tackifier , 10 parts of plasticizer, 10 parts of filler, 10 parts of reinforcing agent, 0.5 part of coupling agent, 0.1 part of crosslinking agent, 0.1 part of auxiliary crosslinking agent, 1 part of antioxidant and 1 part of light stabilizer.

[0038] Further, the hot-melt reinforcing agent is an amorphous α-olefin copolymer.

[0039] Further, the flux is maleic anhydride grafted polyamide.

[0040] Further, the grafting rate of the fluxing agent is 0.5%.

[0041] Further, the crosslinking agent is dicumyl peroxide.

[0042] Further, the auxiliary crosslinking agent is tripropenyl isocyanurate.

[0043] Further, the butyl rubber is common butyl rubber.

[0044] Further, the tackifier is petroleum resin.

[0045] Further, the plasti...

Embodiment 2

[0058] This embodiment provides a high cohesive strength hot-melt butyl rubber, including the following raw material components in parts by weight: 30 parts of butyl rubber, 15 parts of hot-melt reinforcing agent, 3 parts of flux, and 10 parts of tackifier , 30 parts of plasticizer, 30 parts of filler, 30 parts of reinforcing agent, 1 part of coupling agent, 1 part of crosslinking agent, 1 part of auxiliary crosslinking agent, 3 parts of antioxidant and 3 parts of light stabilizer.

[0059] Further, the hot-melt enhancer is α-methylstyrene.

[0060] Further, the flux is glycidyl methacrylate grafted polyamide.

[0061] Further, the grafting rate of the fluxing agent is 1%.

[0062] Further, the crosslinking agent is phenolic resin.

[0063] Further, the auxiliary crosslinking agent is tripropenyl isocyanurate.

[0064] Further, the butyl rubber is chlorinated butyl rubber.

[0065] Further, the tackifier is rosin resin.

[0066] Further, the plasticizer is 0# naphthenic o...

Embodiment 3

[0079] This embodiment provides a high cohesive strength hot-melt butyl rubber, including the following raw material components in parts by weight: 60 parts of butyl rubber, 30 parts of hot-melt reinforcing agent, 10 parts of flux, and 45 parts of tackifier , 60 parts of plasticizer, 60 parts of filler, 40 parts of reinforcing agent, 5 parts of coupling agent, 3 parts of crosslinking agent, 3 parts of co-crosslinking agent, 5 parts of antioxidant and 5 parts of light stabilizer.

[0080] Further, the hot-melt reinforcing agent is a combination of ethylene-vinyl acetate and vinyl acetate of polyethylene at a ratio of 1:1, wherein the vinyl acetate content of ethylene-vinyl acetate is 30%, and the molecular weight of polyethylene is 3000 .

[0081] Further, the fluxing agent is polyamide grafted with hydroxyethyl methacrylate.

[0082] Further, the grafting rate of the fluxing agent is 1.5%.

[0083] Further, the crosslinking agent is diisobutylbenzene peroxide.

[0084] Furt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com