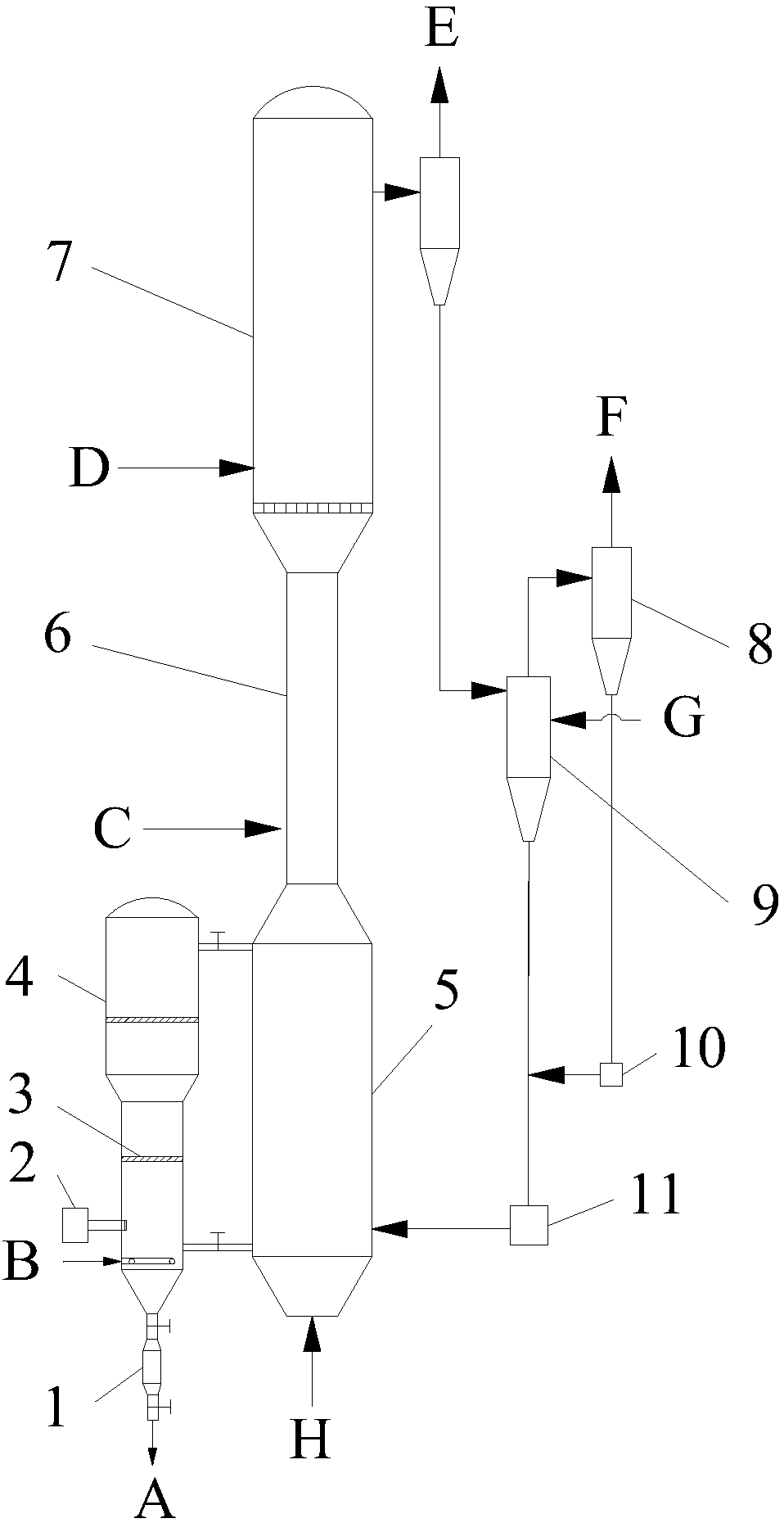

High-efficiency staged conversion combined fluidized bed reaction device and reaction method

A reaction device and combined flow technology, applied in the field of high-efficiency graded conversion combined fluidized bed reaction device, can solve the problems of difficult slagging, low methane yield, low utilization rate of pulverized coal, etc. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

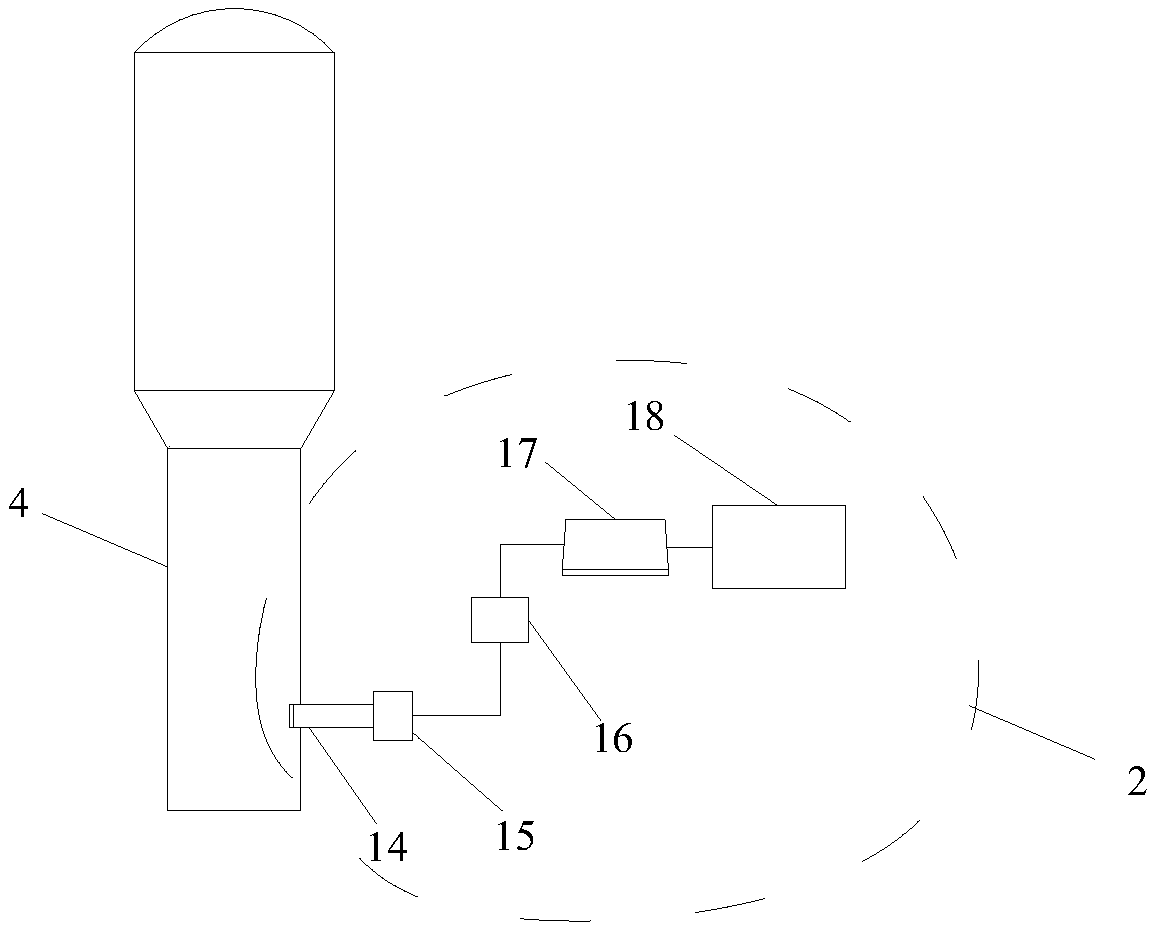

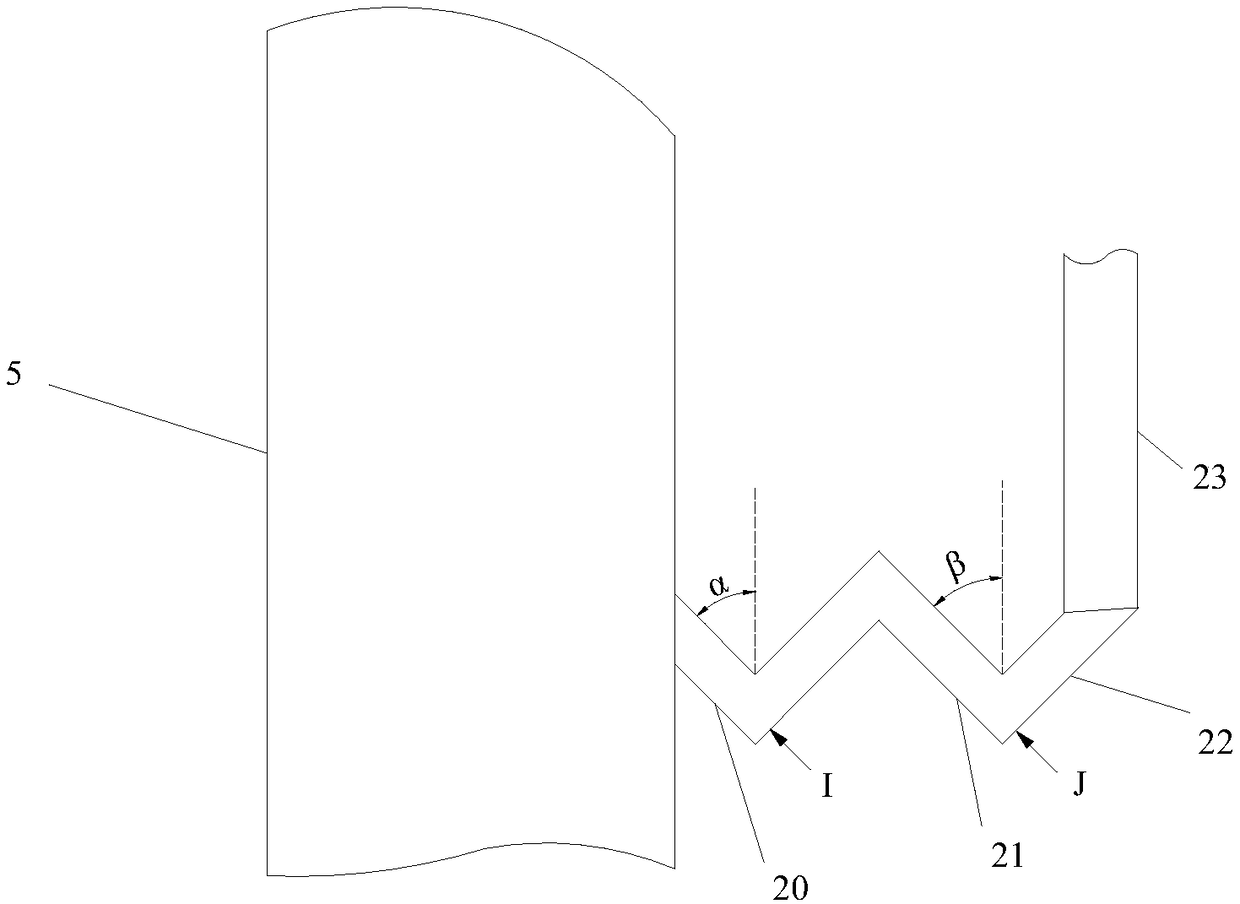

[0038] The carbon-containing raw material loaded with catalyst enters the pyrolysis furnace for rapid pyrolysis, and the pyrolysis gas and semi-coke after pyrolysis are separated in the pyrolysis furnace and cyclone separator, and the coal tar enters the follow-up equipment for purification and separation; after separation The semi-coke flows through the first return mechanism and the second return mechanism respectively, and enters the first reaction zone at the same time as the gasification agent for mixing, combustion and partial gasification reaction. The carbon-containing particles enter the classification and slag discharge device through valve control. After the particle classification, the closed hopper at the bottom is controlled in an orderly manner to discharge large particle slag, while the carbon-containing particles flow into the upper end of the first reaction zone through the upper part of the classification and slag discharge device to continue to participate in...

Embodiment 2

[0041]The carbon-containing raw material loaded with catalyst enters the pyrolysis furnace for rapid pyrolysis, and the pyrolysis gas and semi-coke after pyrolysis are separated in the pyrolysis furnace and cyclone separator, and the coal tar enters the follow-up equipment for purification and separation; after separation The semi-coke flows through the first return mechanism and the second return mechanism respectively, and enters the first reaction zone at the same time as the gasification agent for mixing, combustion and partial gasification reaction. The carbon-containing particles enter the classification and slag discharge device through valve control. After the particle classification, the closed hopper at the bottom is controlled in an orderly manner to discharge large particle slag, while the carbon-containing particles flow into the upper end of the first reaction zone through the upper part of the classification and slag discharge device to continue to participate in ...

Embodiment 3

[0044] The carbon-containing raw material loaded with catalyst enters the pyrolysis furnace for rapid pyrolysis, and the pyrolysis gas and semi-coke after pyrolysis are separated in the pyrolysis furnace and cyclone separator, and the coal tar enters the follow-up equipment for purification and separation; after separation The semi-coke flows through the first return mechanism and the second return mechanism respectively, and enters the first reaction zone at the same time as the gasification agent for mixing, combustion and partial gasification reaction. The carbon-containing particles enter the classification and slag discharge device through valve control. After the particle classification, the closed hopper at the bottom is controlled in an orderly manner to discharge large particle slag, while the carbon-containing particles flow into the upper end of the first reaction zone through the upper part of the classification and slag discharge device to continue to participate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com