Method for promoting biological corrosion resistance of magnesium alloy bone fracture plate

A bone plate and magnesium alloy technology, applied in the direction of outer plate, internal bone synthesis, anodic oxidation, etc., can solve the problems of providing sufficient strength and corrosion too fast, and achieve controllable parameters, improved biocorrosion resistance, and flexible process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

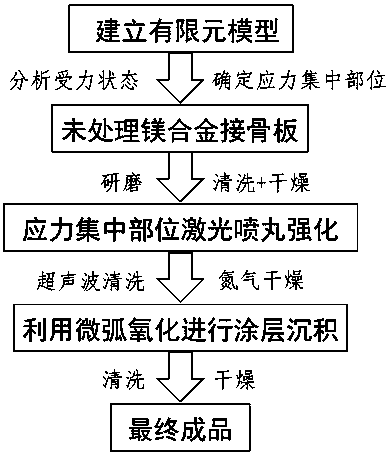

[0016] The process of "a method for improving the biocorrosion resistance of magnesium alloy bone plate" of the present invention is as follows figure 1 As shown, it mainly includes the following steps.

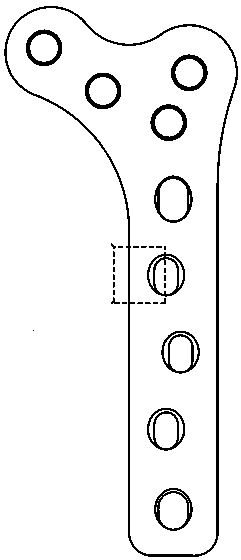

[0017] (1) if figure 2 As shown, the finite element model of the ZK60 magnesium alloy bone plate was established to analyze its stress state in the human body and determine the stress concentration location.

[0018] (2) Grind the ZK60 magnesium alloy bone plate with 280#, 500#, 800#, 1200#, 1500#, 2000# sandpaper to remove surface oxides and surface scratches, and then place the bone plate in acetone for ultrasonic cleaning 10 min, then rinsed with deionized water and dried.

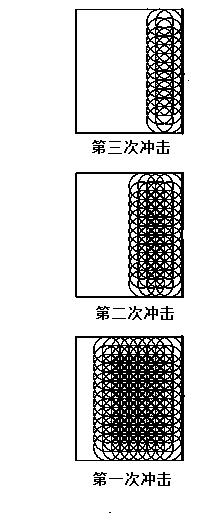

[0019] (3) Paste the aluminum foil absorbing layer on the part of the dried magnesium alloy bone plate that needs to be strengthened and clamp it on the robot of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com