Preparation method of aluminum and aluminum alloy wear-resistant self-lubricating coating

A technology of self-lubricating coatings and aluminum alloys, applied in coatings, electrolytic coatings, etc., can solve problems such as insufficient self-lubricating properties of coatings, easy pulverization, and poor adhesion, so as to avoid secondary damage and improve adhesion Good, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of wear-resistant and self-lubricating coatings on aluminum and aluminum alloys. The base material of the test piece is 7A04-T6 aluminum alloy, the specification is φ90mm×5mm, and the surface is processed to a roughness of Ra≤1.6.

[0069] ① Soak the specimen in acetone for 2 minutes, then wipe it clean with absorbent cotton; then degrease it in an alkaline degreasing solution at 60-75°C for 5-10 minutes; then rinse it with tap water for 30s-60s.

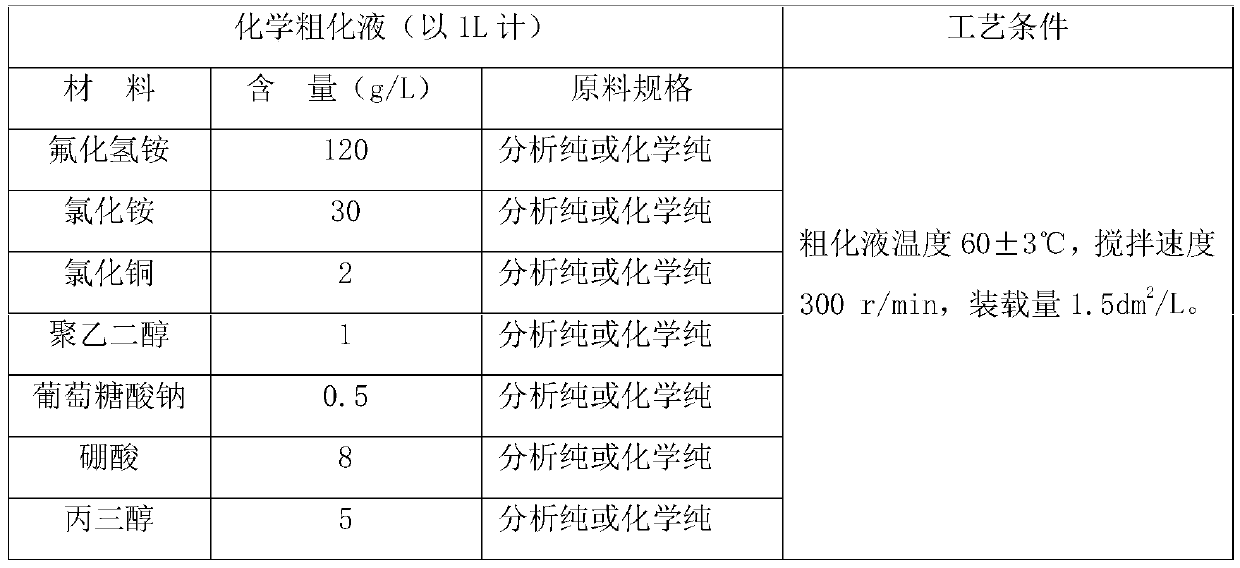

[0070] ②Chemical roughening treatment: Carry out chemical roughening treatment according to the roughening solution and process conditions described in Table 1; time 15min, then rinse with tap water for 30s-60s, until the appearance of the substrate surface is uniform, without roughening such as shiny or blooming unpleasant sight.

[0071] Table 1 Composition and process conditions of chemical roughening solution

[0072]

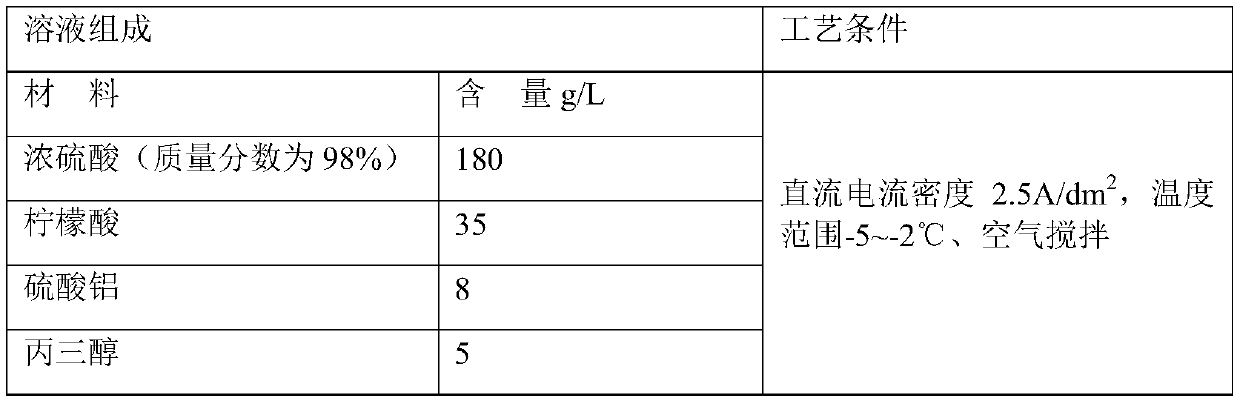

[0073] ③Preparation of self-lubricating coating A: The self-lubricating coating is prep...

Embodiment 2

[0081] Preparation of wear-resistant and self-lubricating coatings on aluminum and aluminum alloys. The base material of the test piece is 6063-T6 aluminum alloy, the specification is φ90mm×5mm, and the surface is processed to a roughness of Ra≤1.6.

[0082] ① Soak the specimen in acetone for 2 minutes, then wipe it clean with absorbent cotton; then degrease it in an alkaline degreasing solution at 60-75°C for 5-10 minutes; then rinse it with tap water for 30s-60s.

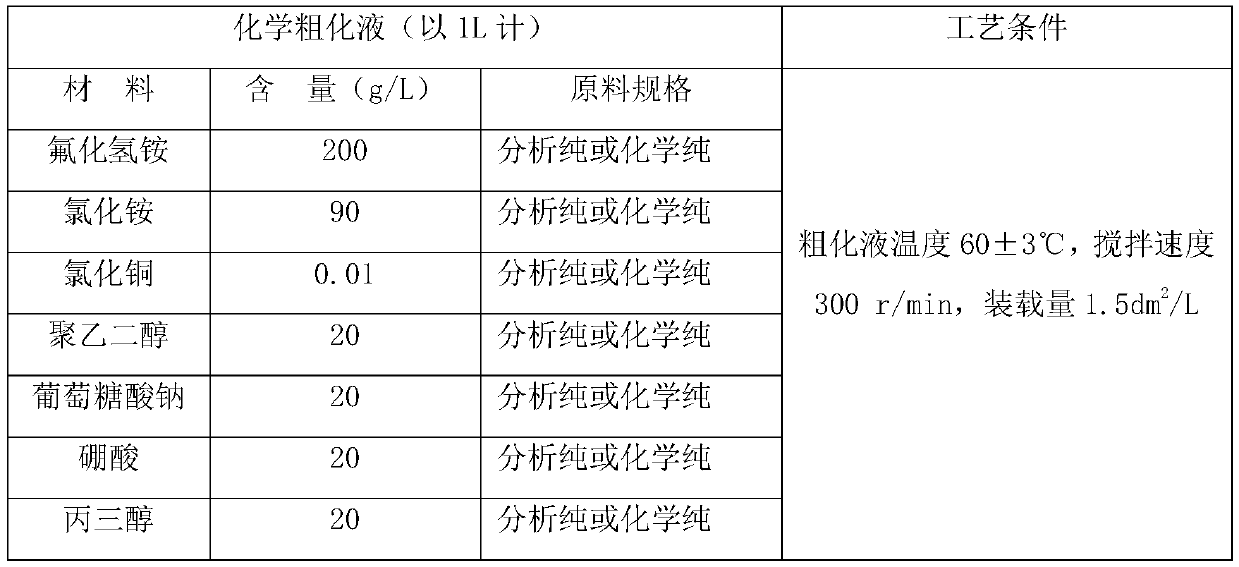

[0083] ②Chemical roughening treatment: Carry out chemical roughening treatment according to the roughening solution and process conditions described in Table 3; time 15min, then rinse with tap water for 30s-60s, until the appearance of the substrate surface is uniform, without roughening such as shiny or blooming unpleasant sight.

[0084] Table 3 Composition and process conditions of chemical roughening solution

[0085]

[0086] ③Preparation of self-lubricating coating A: The self-lubricating coating was pre...

Embodiment 3

[0093] Preparation of wear-resistant and self-lubricating coatings on aluminum and aluminum alloys. The base material of the test piece is 7A04-T6 aluminum alloy, the specification is φ90mm×5mm, and the surface is processed to a roughness of Ra≤1.6.

[0094]① Soak the specimen in acetone for 2 minutes, then wipe it clean with absorbent cotton; then degrease it in an alkaline degreasing solution at 60-75°C for 5-10 minutes; then rinse it with tap water for 30s-60s.

[0095] ②Mechanical roughening treatment: the selected abrasive is 100 mesh 50% corundum + 50% glass sand, and the sample is sandblasted. After sandblasting until the surface of the sample is uniform, use organic solvents such as acetone or ethyl acetate. The sample surface was cleaned and dried.

[0096] ③Preparation of self-lubricating coating A: The self-lubricating coating was prepared on the surface of the substrate by air spraying method, wherein the coating was CP02 self-lubricating coating, and the solid com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com