Electrolytic decontamination method

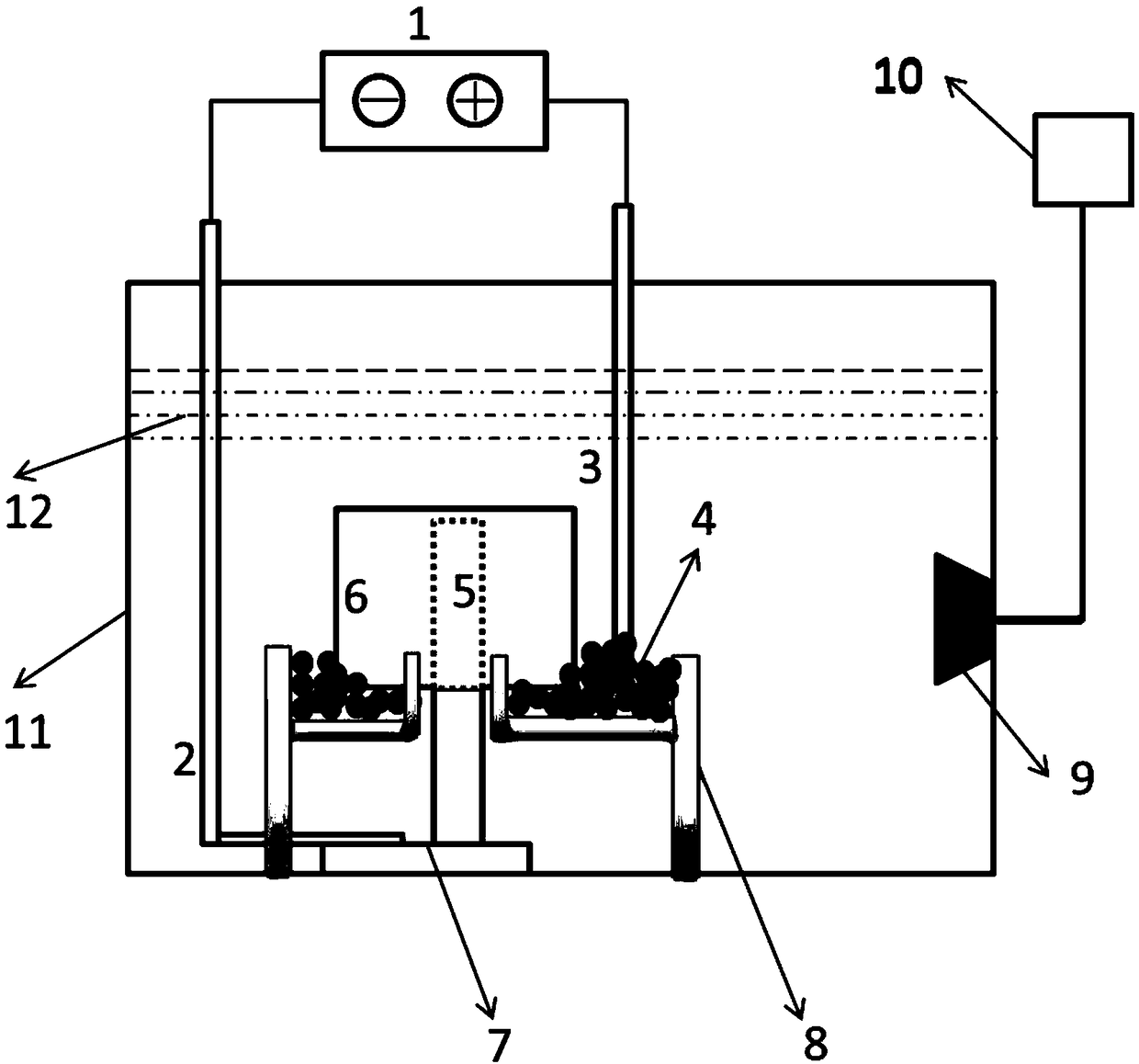

An electrolyte and ultrasonic technology, applied in the field of pipe fittings treatment, can solve the problems of low electrolysis efficiency, discontinuous electrolysis process, difficulty in increasing current utilization efficiency, etc., and achieve the effect of optimizing decontamination effect and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An electrolytic decontamination method, comprising the following steps: under ultrasonic conditions, using titanium as the anode and platinum as the cathode, under the action of conductive balls, decontaminating metal pipe fittings polluted by radionuclide cobalt and silver at 40°C Electrolytic decontamination; the frequency of the ultrasound is 28kHz; the current density is 2000A / m 2 The distance between the anode and the cathode is 15mm; the electrolyte includes nitric acid with a mass concentration of 10% and sulfuric acid with a mass concentration of 10%; the electrolysis time is 10min;

[0036] Under the situation that above-mentioned parameter is determined, research the impact of conductive pellet material on electrolytic decontamination efficiency: described conductive pellet is respectively the particle diameter of 2mm copper particle, titanium particle, lead particle and graphene pellet particle; Simultaneously study The electrolytic decontamination rate witho...

Embodiment 2

[0040] An electrolytic decontamination method, comprising the following steps: under ultrasonic conditions, using titanium as an anode and platinum as a cathode, under the action of conductive balls, performing electrolytic decontamination on metal pipe fittings contaminated by uranium at 40°C; The frequency of the ultrasound is 28kHz; the current density is 2000A / m 2 ; In the electrolyte, the mass concentration is 10% phosphoric acid and 10% sulfuric acid; the conductive ball is a titanium ball with a particle diameter of 2 mm;

[0041] In the case of determining the above parameters, the influence of the distance between the cathode and the anode on the electrolytic decontamination efficiency is studied: the distance between the cathode and the anode is 13mm, 15mm, 19mm, 25mm according to the inner diameter of different contaminated metal pipes, and the electrolysis time is 5min; The electrolytic decontamination efficiency of the contaminated metal pipe fittings was measured...

Embodiment 3

[0045] An electrolytic decontamination method, comprising the following steps: under ultrasonic conditions, using titanium as the anode and platinum as the cathode, and under the action of titanium conductive balls, the surface pollution is 15.3Bq / cm at 40°C 2 The polluted metal pipe fittings are electrolyzed and decontaminated; the frequency of the ultrasound is 40kHz; the current density is 2000A / m 2 ; The distance between the anode and the cathode is 15mm;

[0046] Under the situation that above-mentioned parameter is determined, research different electrolytes to the influence of electrolysis decontamination rate: wherein one electrolyte is the sulfuric acid that mass concentration is 20%; Include mass concentration in an electrolyte liquid and be that the phosphoric acid of 10% and mass concentration are 10% sulfuric acid; one electrolyte includes nitric acid with a mass concentration of 10% and sulfuric acid with a mass concentration of 10%; after electrolysis for 10 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com