Carbon-coated aluminum foil and preparation method thereof

A technology of carbon-coated aluminum foil and aluminum foil, which is applied in the direction of electrode carriers/collectors, electrical components, battery electrodes, etc., can solve the problems of increased production costs, poor heat dissipation, and weak electrical conductivity, etc., to increase energy density and reduce poles. The effect of chemicalization and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

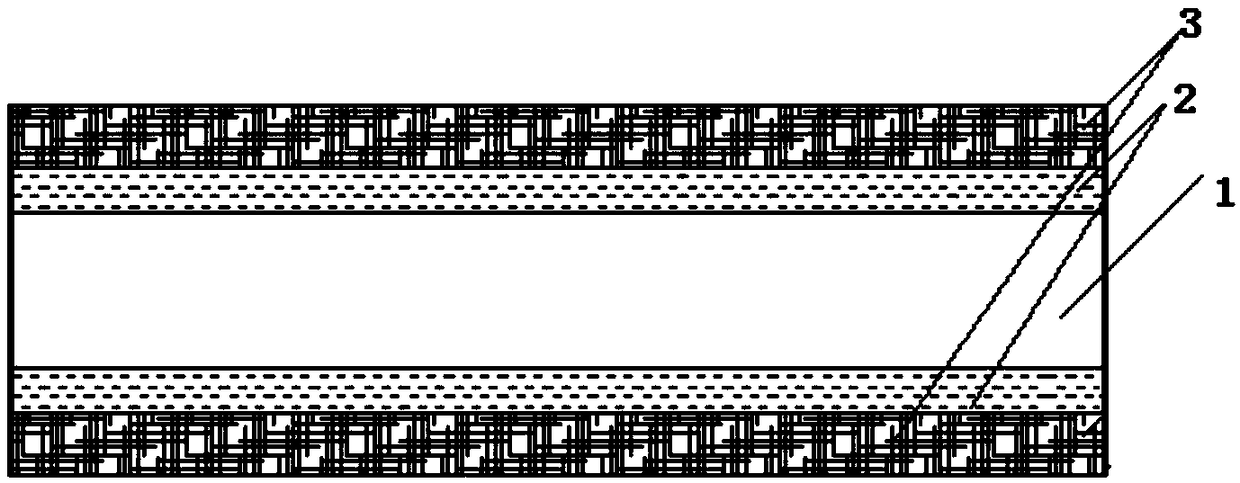

[0033] An aluminum foil body, such as figure 1 As shown, the aluminum foil body 1, the CNT+Super P composite conductive layer 2 and the CNT conductive layer 3 are sequentially formed from the inside to the outside.

[0034] The preparation method of the carbon-coated aluminum foil is as follows:

[0035] 1) First, pre-treat the aluminum foil: use acetic acid to remove dirt and impurities on the surface of the aluminum foil;

[0036] 2) Mix the polytetrafluoroethylene and ethanol uniformly, then add CNT and Super P conductive agent, mix uniformly, and obtain a composite conductive slurry. Among them, the solid content of the composite conductive paste is 25%, the mass fraction of CNT is 15%, the mass fraction of Super P is 10%, the binder content is 5%, and the slurry viscosity is 250 mPa·S.

[0037] 3) Put the conductive slurry into the electrospinning device, adjust the electrospinning voltage to 20kV, and the solution flow rate to 2mL·h -1 , The distance between the electrostatic sp...

Embodiment 2

[0044] An aluminum foil body is composed of an aluminum foil body, a CNT+graphene composite conductive layer, and a CNT conductive layer 3 from the inside to the outside.

[0045] The preparation method of the carbon-coated aluminum foil is as follows:

[0046] 1) First, pre-treat the aluminum foil: use acetic acid to remove dirt and impurities on the surface of the aluminum foil;

[0047] 2) Mix the polytetrafluoroethylene and ethanol evenly, and then add the CNT and graphene conductive agent, and mix evenly to obtain a composite conductive paste. Among them, the solid content of the composite conductive paste is 15%, the mass fraction of CNT is 5%, the mass fraction of graphene is 10%, the binder content is 5%, and the slurry viscosity is 250 mPa·S.

[0048] 3) Put the conductive slurry into the electrospinning device, adjust the electrospinning voltage to 20kV, and the solution flow rate to 2mL·h -1 , The distance between the electrostatic spinning nozzle and the aluminum foil is 5...

Embodiment 3

[0052] An aluminum foil body is composed of an aluminum foil body, a CNT+Super P+graphene composite conductive layer and a CNT conductive layer 3 from the inside to the outside.

[0053] The preparation method of the carbon-coated aluminum foil is as follows:

[0054] 1) First, pre-treat the aluminum foil: use acetic acid to remove dirt and impurities on the surface of the aluminum foil;

[0055] 2) Mix the polytetrafluoroethylene and ethanol evenly, and then add CNT, Super P and graphene conductive agent, and mix evenly to obtain a composite conductive paste. Among them, the solid content of the composite conductive paste is 30%, the mass fraction of CNT is 15%, the mass fraction of graphene is 10%, the mass fraction of Super P is 5%, the binder content is 5%, and the slurry viscosity is 250 mPa·S.

[0056] 3) Put the conductive slurry into the electrospinning device, adjust the electrospinning voltage to 20kV, and the solution flow rate to 2mL·h -1 , The distance between the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com