Blood glucose regulating polymer vesicle as well as preparation method and application thereof

A technology of polymers and vesicles, applied in the field of polymer materials and medicine, can solve the problems of difficulty and limited research on sugar-responsive assemblies, and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036]

[0037] The preparation method of the blood sugar regulating polymersome of the present invention comprises the following steps:

[0038] (1), the synthetic steps of amphiphilic sugar-containing polymer:

[0039] a. Using trithioester-modified polyoxyethylene (PEO-DDMAT) as a chain transfer agent, the coumarin monomer (CMA), phenylboronic acid monomer (AAPBA), glucose monomer (AGA), initiator and the second A class of solvents are mixed and reacted at 70-150°C for 10-60 hours under anaerobic conditions. After the reaction is completed, a polymer solution is obtained;

[0040] b. obtaining the polymer powder after rotary evaporation, dissolving, dialysis and lyophilization of the obtained polymer solution;

[0041] (2) Preparation steps of blood sugar regulating polymersomes:

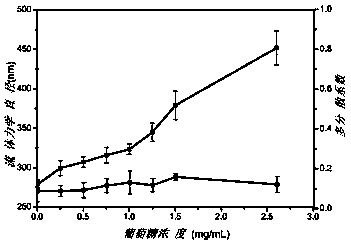

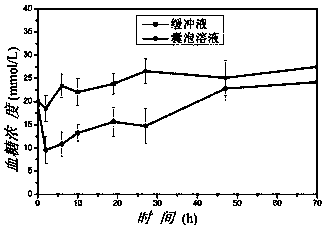

[0042] Dissolve the amphiphilic sugar-based polymer PEO-b-P (CMA-stat-AAPBA-stat-AGA) obtained in step (1) in the second type of solvent at a concentration of 1.0 to 10 mg / mL, and stir vigoro...

Embodiment 1

[0057] This embodiment provides a method for preparing blood sugar regulating polymersomes, comprising the following steps:

[0058] (1), the synthesis steps of the amphiphilic sugar-containing polymer PEO-b-P (CMA-stat-AAPBA-stat-AGA):

[0059] a. Use 0.115g (0.05mmol) polyoxyethylene (PEO-DDMAT) modified by trithioester as chain transfer agent, 0.002g azobisisobutyronitrile (AIBN) as initiator, coumarin monomer (CMA ) (0.295g, 1.0mmol), phenylboronic acid monomer (AAPBA) (0.619g, 0.8mmol) and glucose monomer (AGA) (0.113g, 0.5mmol) were added together into a 25mL round bottom flask, and 5mL di Methyl sulfoxide dissolves all the above-mentioned reactants, and blows argon for 30 minutes by bubbling to remove oxygen in the reaction system (form an oxygen-free environment), and carry out chain transfer radical polymerization (RAFT), and the reaction temperature is 75 °C, the reaction time is 60h, and after the reaction is completed, a polymer solution is obtained;

[0060] b. ...

Embodiment 2

[0066] This embodiment provides a method for preparing blood sugar regulating polymersomes, comprising the following steps:

[0067] (1), the synthesis steps of the amphiphilic sugar-containing polymer PEO-b-P (CMA-stat-AAPBA-stat-AGA):

[0068] a. Use 0.115g (0.05mmol) trithioester-modified polyoxyethylene (PEO-DDMAT) as chain transfer agent, 0.004g azobisisobutyronitrile (AIBN) as initiator, coumarin monomer (CMA ) (0.443g, 1.5mmol), phenylboronic acid monomer (AAPBA) (0.923g, 1.2mmol) and glucose monomer (AGA) (0.113g, 0.5mmol) were added together into a 25mL round bottom flask, Methyl sulfoxide / dimethylformamide mixed solvent to dissolve all the above-mentioned reactants, and blow argon for 30 minutes by bubbling method to remove oxygen in the reaction system (form an oxygen-free environment), and carry out chain transfer radical polymerization reaction (RAFT), the reaction temperature is 100°C, and the reaction time is 40h. After the reaction, a polymer solution is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com