Medical material for inducing tissue repair as well as preparation method and application thereof

A technology for tissue repair and loading materials, which is applied in the field of medical materials, and can solve problems such as the inability to provide surface cells on materials, the non-specificity of intervening scaffold materials, and the selective growth microenvironment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

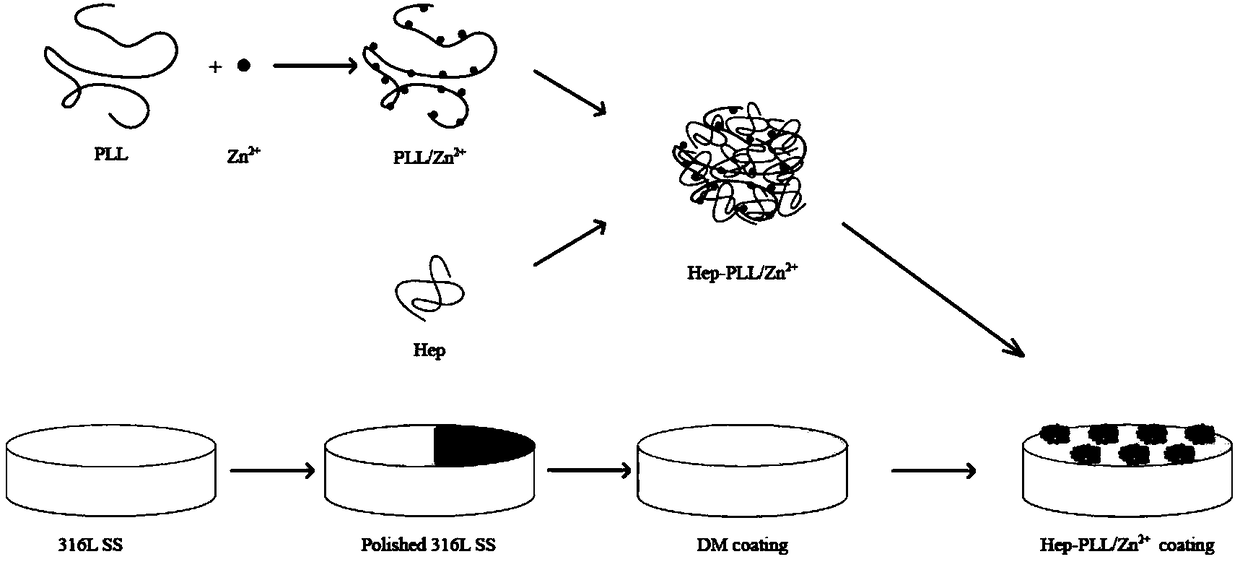

[0024] An embodiment of the present invention provides a method for preparing a medical material for inducing tissue repair, which includes the following steps:

[0025] S1. Depositing a polydopamine coating on the material to be loaded

[0026] Specifically, the preparation process of the material to be loaded with the polydopamine coating deposited includes: immersing the material to be loaded in a mixed solution formed of trishydroxymethylaminomethane and dopamine for 6-12 hours. Dopamine can be mixed with high-concentration tris to undergo self-polymerization and form a coating on the surface of the material. The concentration of Tris can be 1-2 mg / mL, and the concentration of dopamine can be 1-3 mg / mL.

[0027] What needs to be added is that the operation of depositing the polydopamine coating on the material can be selected according to the needs. If the material that has already deposited the polydopamine coating is directly used, this step will not be performed.

[0...

Embodiment 1

[0046] This embodiment provides a method for preparing a medical material for inducing tissue repair, which includes the following steps:

[0047] First, mix 1 mg / mL tris solution with an equal volume of 1 mg / mL dopamine solution to form a mixed solution, place a 316L stainless steel plate in the mixed solution for 6 hours, wash it with water three times, and then dry it at 37°C spare.

[0048] Secondly, 0.0005mmol / L zinc chloride solution was added dropwise to a polylysine solution with a concentration of 0.3mg / mL and a weight-average molecular weight of 150KDa, and stirred for 2h; then, under the condition of magnetic stirring, after the reaction, Add 5 mg / mL sodium heparin dropwise to the mixed solution to obtain nanoparticle suspension and react at room temperature for 2 hours, wherein the volume ratio of zinc chloride solution, polylysine solution and sodium heparin solution is about 1:0.9:1.8 .

[0049] Finally, the stainless steel plate with the polydopamine coating d...

Embodiment 2

[0051] This embodiment provides a method for preparing a medical material for inducing tissue repair, which includes the following steps:

[0052] First, mix a 2mg / mL tris solution with an equal volume of a 3mg / mL dopamine solution to form a mixed solution, place a 316L stainless steel plate in the mixed solution for 12 hours, wash it with water three times, and then dry it at 37°C spare.

[0053] Next, add 10mmol / L zinc chloride solution dropwise into polylysine solution with a concentration of 1.0mg / mL and a weight-average molecular weight of 300KDa, and stir for 3h; Add 10 mg / mL heparin sodium dropwise to the solution and react at room temperature for 3 hours, wherein the volume ratio of the zinc chloride solution, polylysine solution and heparin sodium solution is about 1:1.1:2.2.

[0054] Finally, the stainless steel plate with the polydopamine coating deposited on the surface was soaked in the nanoparticle suspension, shaken and reacted at room temperature for 24 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com