Silicate-coated titanium dioxide photocatalyst powder and preparation method thereof

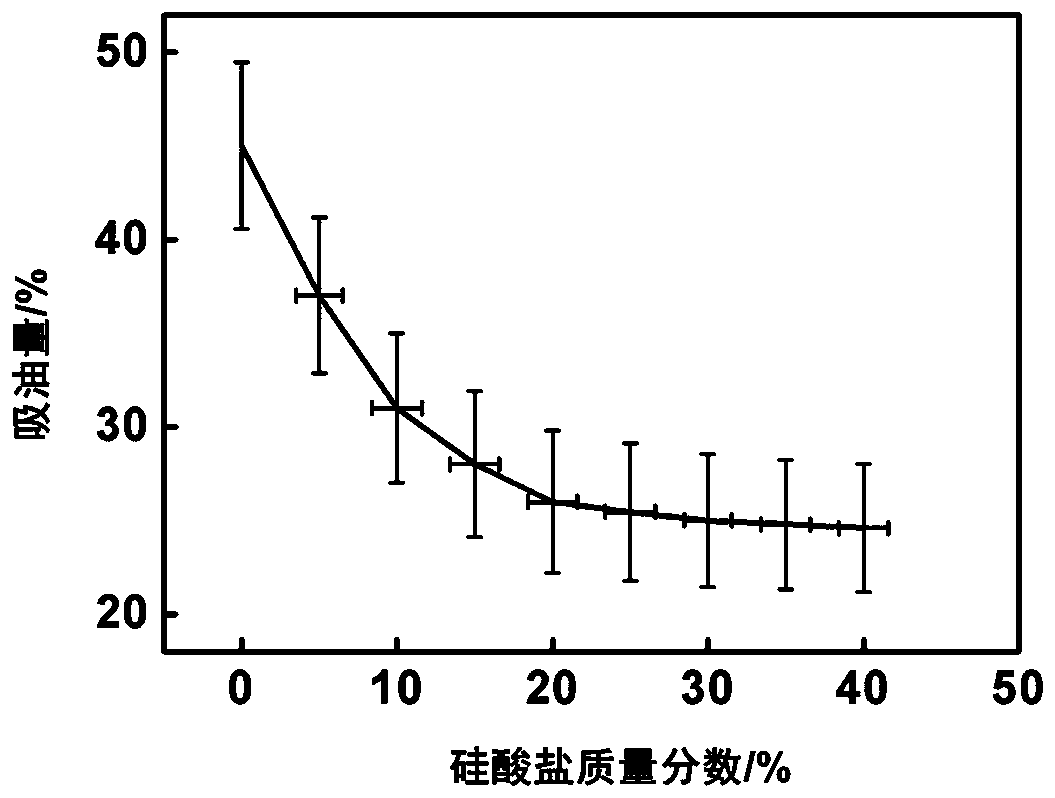

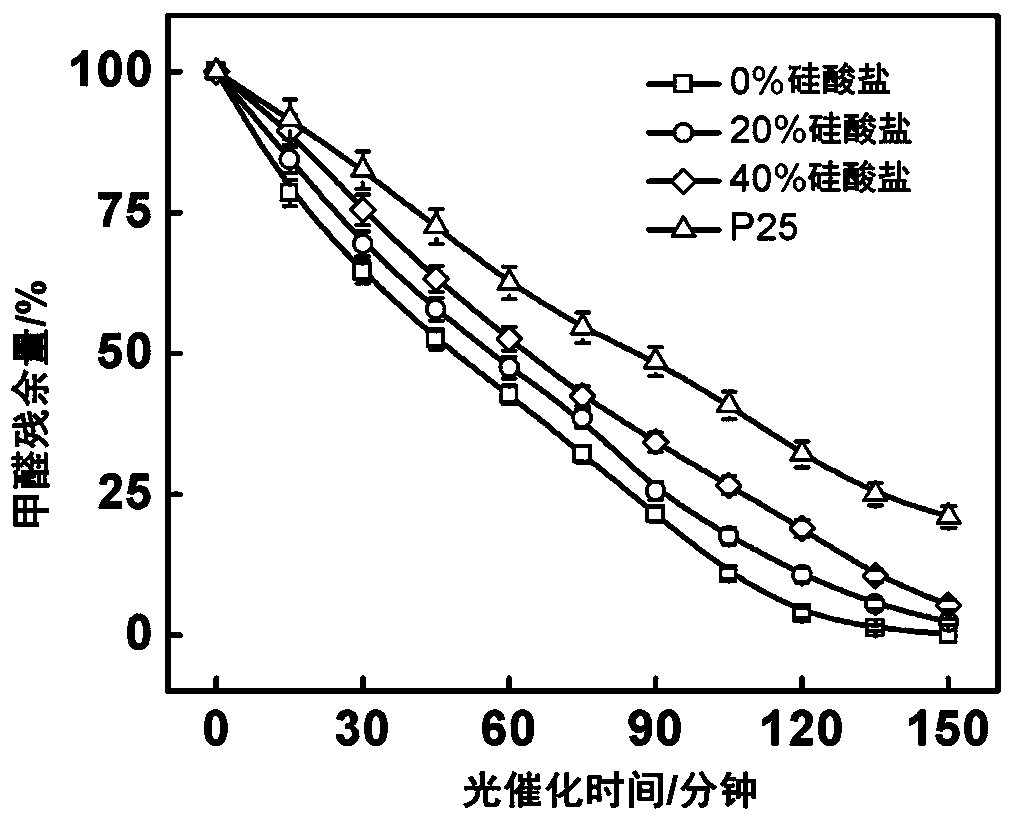

A titanium dioxide and photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of difficult dispersion of titanium dioxide, unstable adsorption, low coating rate, etc., and achieve improved photochemical stability, excellent water and oil phase dispersibility, and photocatalytic activity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (preparation of titanium dioxide photocatalyst powder with a silicate mass fraction of about 5%)

[0035](1) Add photocatalyst titanium dioxide to absolute ethanol, shake and stir for 1 hour until titanium dioxide is completely dispersed into dispersion A, wherein the mass percentage of photocatalyst titanium dioxide in dispersion A is 5%; stir while dispersing A saturated solution of sodium bicarbonate was added dropwise to liquid A until the pH was adjusted to 8 to obtain dispersion B.

[0036] (2) Add the liquid aminosilane coupling agent KH-540 dropwise to the dispersion B, and heat the dispersion B to 80°C at the same time, the amount of KH-540 added is 1.2% of the volume fraction of the dispersion B; Under ambient conditions, stir at a low speed to react for 4 hours; stop heating and allow it to cool to room temperature, filter the dispersion B to obtain solid C, wash and filter solid C alternately and repeatedly with absolute ethanol and 10% dilute sulfuric acid ...

Embodiment 2

[0042] (preparation of titanium dioxide photocatalyst powder with about 10% silicate mass fraction)

[0043] (1) Add photocatalyst type titanium dioxide to absolute ethanol, shake and stir for 0.8 hours until titanium dioxide is completely dispersed into dispersion A, wherein the mass percentage of photocatalyst type titanium dioxide in dispersion A is 5%; stir while dispersing A saturated solution of sodium bicarbonate was added dropwise to liquid A until the pH was adjusted to 8 to obtain dispersion B.

[0044] (2) Then add aminosilane coupling agent KH-550 dropwise to the dispersion B while heating, the amount of KH-550 added is 1.0% of the volume fraction of the dispersion B; Under the condensing and reflux environment, stir at high speed to make it react for 2 hours; stop heating and let it cool to room temperature, filter the dispersion B to obtain the solid C, alternately wash and filter the solid C with absolute ethanol and 10% dilute sulfuric acid , until the pH of t...

Embodiment 3

[0050] (preparation of titanium dioxide photocatalyst powder with about 30% silicate mass fraction)

[0051] (1) Add photocatalyst titanium dioxide to absolute ethanol, shake and stir for 1 hour until titanium dioxide is completely dispersed into dispersion A, wherein the mass percentage of photocatalyst titanium dioxide in dispersion A is 1.2%; stir to disperse Saturated sodium bicarbonate solution was added dropwise to solution A until the pH was adjusted to 9.

[0052] (2) After heating to 80°C, start to condense and reflux, add the aminosilane coupling agent SG-Si902 dropwise to the dispersion A within 1 hour, and continue to condense and reflux for 3 hours to obtain the dispersion B, SG-Si902 The amount added is 0.8% of the volume fraction of the dispersion B; stop heating and allow it to cool to room temperature, filter the dispersion B to obtain the solid C, alternately wash and filter the solid C with absolute ethanol and 10% dilute sulfuric acid, Until the pH of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com