Nano-Pd/M-rGO composite catalyst and preparation method thereof

A composite catalyst and nanotechnology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of catalyst catalytic activity and stability reduction, catalyst specific surface area reduction, etc., to improve activity and stability, and the effect of improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

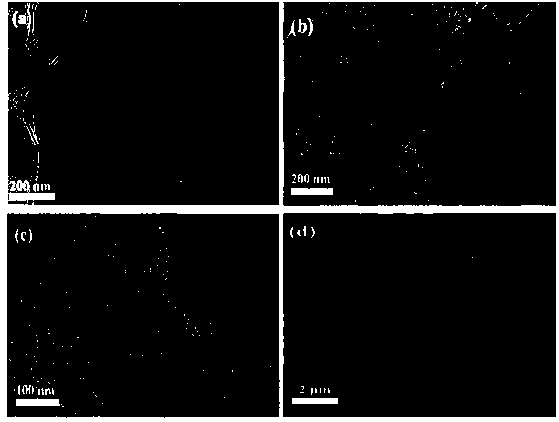

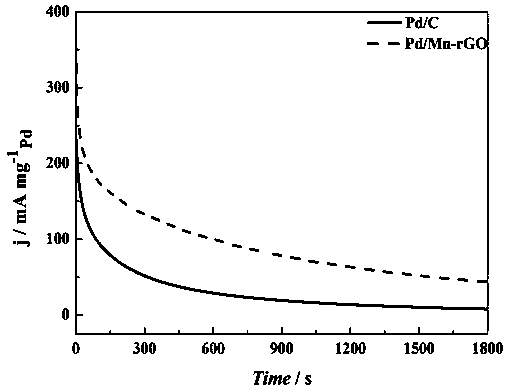

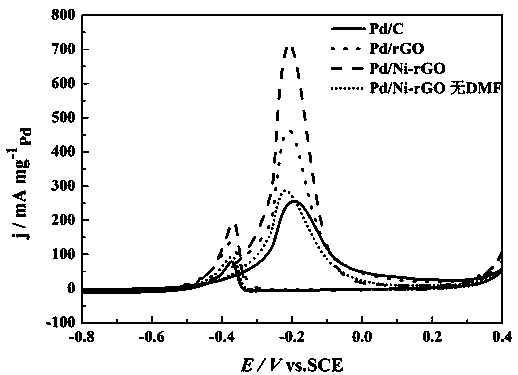

[0052] Embodiment 1: In this embodiment, the nano-Pd / M-rGO composite catalyst is a nano-Pd / Ni-rGO composite catalyst, wherein rGO is reduced graphene oxide, and the loading of Pd is 20% of the composite catalyst mass;

[0053] The preparation method of the present embodiment nano-Pd / Ni-rGO composite catalyst, concrete steps are as follows:

[0054] (1) Add graphene oxide to N,N-dimethylformamide for ultrasonic exfoliation for 1.5h to obtain graphene oxide suspension; the concentration of graphene oxide suspension is 2mg / mL;

[0055] (2) The transition metal nickel salt solution (NiSO 4 Solution) and the graphene oxide suspension in step (1) were mixed evenly, and the temperature was 190 °C, hydrothermal reaction for 24 hours, cooled to room temperature, filtered, washed, freeze-dried, and then placed at a temperature of 850 °C in an Ar atmosphere The Ni-rGO composite was obtained by constant temperature treatment for 2 h; the transition metal salt solution (NiSO 4 solution) ...

Embodiment 2

[0075] Embodiment 2: In this embodiment, the nano-Pd / M-rGO composite catalyst is a nano-Pd / Co-rGO composite catalyst, wherein rGO is reduced graphene oxide, and the loading capacity of Pd is 17% of the composite catalyst mass;

[0076] The preparation method of the present embodiment nanometer Pd / Co-rGO composite catalyst, concrete steps are as follows:

[0077] (1) Add graphene oxide to N,N-dimethylformamide for ultrasonic exfoliation for 3 hours to obtain a graphene oxide suspension; the concentration of the graphene oxide suspension is 1 mg / mL;

[0078] (2) The transition metal cobalt salt solution (Co(NO 3 ) 2 solution) and the graphene oxide suspension in step (1) were evenly mixed, reacted at a temperature of 170 °C for 16 hours under stirring conditions, cooled to room temperature, filtered, washed, freeze-dried, and then placed at a temperature of 700 °C under Ar gas Constant temperature treatment under atmosphere for 1.5h obtains Co-rGO composite material; wherein t...

Embodiment 3

[0085] Embodiment 3: nanometer Pd / M-rGO composite catalyst is nanometer Pd / Fe-rGO composite catalyst in the present embodiment, and wherein rGO is reduced graphene oxide, and the loading capacity of Pd is 19% of composite catalyst quality;

[0086] The preparation method of the nanometer Pd / Fe-rGO composite catalyst of this embodiment, the specific steps are as follows:

[0087] (1) Add graphene oxide to N,N-dimethylformamide for ultrasonic exfoliation for 2.5 hours to obtain graphene oxide suspension; the concentration of graphene oxide suspension is 0.8mg / mL;

[0088] (2) Transition metal iron salt solution (FeCl 2 solution) and the graphene oxide suspension in step (1) were evenly mixed, reacted at 170°C for 18 hours under stirring conditions, cooled to room temperature, filtered, washed, freeze-dried, and then placed at 600°C under Ar gas The Fe-rGO composite was obtained by constant temperature treatment for 1.8 h in the atmosphere; the transition metal iron salt solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com