Prussian blue/tungsten trioxide electrochromic film and preparation method thereof

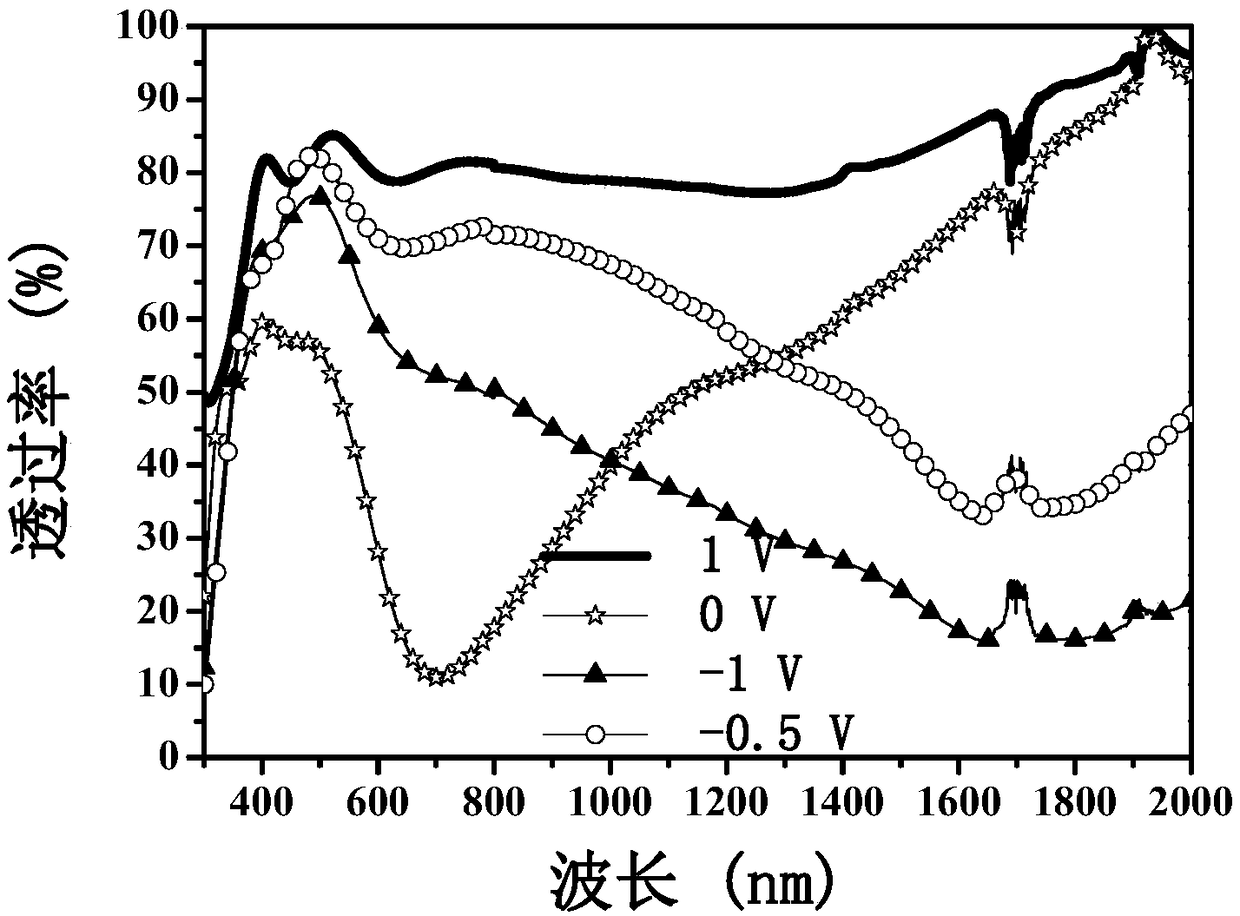

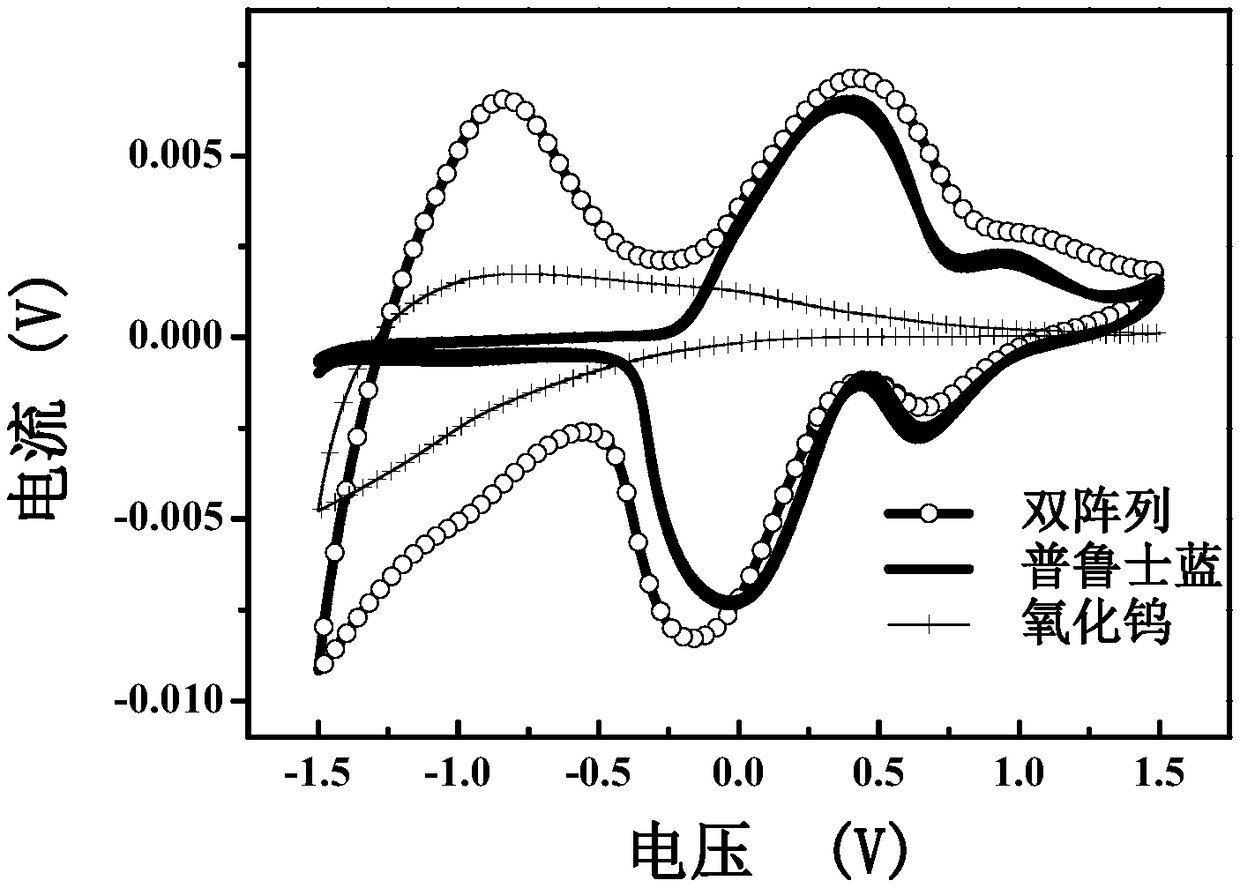

A technology of tungsten trioxide and Prussian blue, which is applied in the direction of tungsten oxide/tungsten hydroxide, ferricyanide, metal cyanide, etc., can solve the problem of inability to selectively adjust light and heat in the visible and near-infrared bands, low coloring efficiency, Narrow modulation range and other issues, to improve coloring efficiency, facilitate embedding and extraction, and achieve selective modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Clean the substrate: Clean the glass slide and ITO conductive glass sequentially with acetone, ethanol, and deionized water for 30 minutes, and then dry them with a plasma cleaner for 3 minutes to obtain clean glass slides and ITO conductive glass;

[0050] (2) Prepare the template:

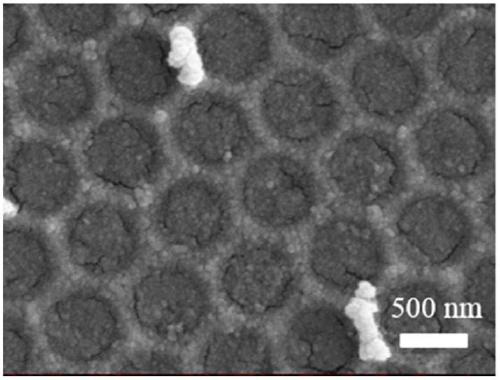

[0051] a. Drop the suspension containing polystyrene microspheres onto the clean glass slide of step (1) to flatten, and dry to obtain a glass slide with polystyrene microspheres; the polystyrene microspheres in the suspension The spherical particle size is 500nm;

[0052] b. Put the glass slide flat on the water surface, pick up the polystyrene microspheres with the clean ITO conductive glass in step (1), and heat at 110°C for 1 min to obtain a polystyrene template with a single layer of polystyrene microspheres spread ;

[0053] (3) Electrochemical deposition of tungsten trioxide film: Dissolve sodium tungstate, hydrogen peroxide and hydrochloric acid in water to form an electrodep...

Embodiment 2

[0059] (1) Clean the substrate: Clean the glass slide and FTO conductive glass sequentially with acetone, ethanol, and deionized water for 40 minutes, and then dry them with a plasma cleaner for 1 minute to obtain clean glass slides and FTO conductive glass;

[0060] (2) Prepare the template:

[0061] a. Drop the suspension containing polystyrene microspheres onto the clean glass slide of step (1) to flatten, and dry to obtain a glass slide with polystyrene microspheres; the polystyrene microspheres in the suspension The spherical particle size is 200nm;

[0062] b. Put the glass slide flat on the water surface, pick up the polystyrene microspheres with the clean FTO conductive glass in step (1), and heat at 100°C for 3 minutes to obtain a polystyrene template with a single layer of polystyrene microspheres spread ;

[0063] (3) Electrochemical deposition of tungsten trioxide film: Dissolve sodium tungstate, hydrogen peroxide and hydrochloric acid in water to form an electro...

Embodiment 3

[0067] (1) Clean the substrate: Clean the glass slide and ITO conductive glass sequentially with acetone, ethanol, and deionized water for 20 minutes, and then dry them with a plasma cleaner for 10 minutes to obtain clean glass slides and ITO conductive glass;

[0068] (2) Prepare the template:

[0069] a. Drop the suspension containing polystyrene microspheres onto the clean glass slide of step (1) to flatten, and dry to obtain a glass slide with polystyrene microspheres; the polystyrene microspheres in the suspension The spherical particle size is 2μm;

[0070] b. Put the glass slide flat on the water surface, pick up the polystyrene microspheres with the clean ITO conductive glass in step (1), and heat at 90°C for 5 minutes to obtain a polystyrene template with a single layer of polystyrene microspheres spread ;

[0071] (3) Electrochemical deposition of tungsten trioxide film: Dissolve sodium tungstate, hydrogen peroxide and hydrochloric acid in water to form an electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com