Humic acid compound fertilizer and preparation method thereof

A compound fertilizer and humic acid technology, which is applied in the direction of urea compound fertilizer, organic fertilizer, excretion fertilizer, etc., can solve the problems of resource utilization constraints, sanitation, safety and environmental pollution, and improve the quality of agricultural products, increase the adsorption structure, and superior growth environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

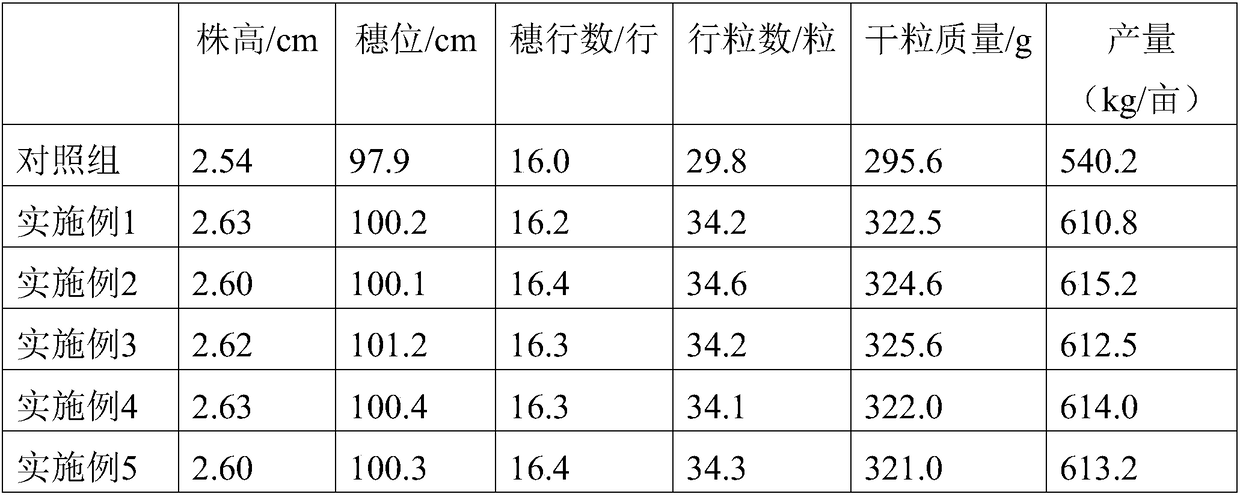

Examples

Embodiment 1

[0024] This embodiment provides a humic acid compound fertilizer, which is made of the following raw materials in parts by weight: 45 parts of pond sugar sludge, 15 parts of cow dung, 15 parts of wheat straw, 8 parts of modified attapulgite, and 4 parts of vermiculite powder , 20 parts of urea, 15 parts of manganese sulfate, 8 parts of potassium humate, and 15 parts of zinc sulfate.

[0025] Wherein, the preparation method of the modified attapulgite is to first soak the attapulgite with hydrochloric acid with a concentration of 20% by mass for 1.5 hours, let it stand, clarify, centrifuge, wash the solid with water until it is neutral, dry it, and then add 2 parts of ethylenediaminetetraacetic acid and 0.8 part of silane coupling agent KH550, stirred evenly, dried, and crushed into powder. Wherein, the water content of the sludge is 55%.

[0026] The preparation method of present embodiment humic acid compound fertilizer comprises the following steps:

[0027] (1) Wheat stal...

Embodiment 2

[0033] This embodiment provides a humic acid compound fertilizer, which is made of the following raw materials in parts by weight: 30 parts of pond sugar sludge, 20 parts of cow dung, 10 parts of wheat straw, 10 parts of modified attapulgite, and 3 parts of vermiculite powder , 25 parts of urea, 12 parts of manganese sulfate, 10 parts of potassium humate, and 12 parts of zinc sulfate.

[0034] Wherein, the preparation method of the modified attapulgite is to first soak the attapulgite with hydrochloric acid with a concentration of 18% by mass for 2 hours, let it stand, clarify, centrifuge, wash the solid with water until it is neutral, dry it, and then add 3 parts of ethylenediaminetetraacetic acid and 0.5 part of silane coupling agent KH550, stirred evenly, dried, and crushed into powder.

[0035] Wherein, the water content of the sludge is 50%.

[0036] The preparation method of present embodiment humic acid compound fertilizer comprises the following steps:

[0037] (1) W...

Embodiment 3

[0043] This embodiment provides a humic acid compound fertilizer, which is made of the following raw materials in parts by weight: 60 parts of pond sugar sludge, 10 parts of cow dung, 20 parts of corn stalks, 5 parts of modified attapulgite, and 5 parts of vermiculite powder , 15 parts of urea, 18 parts of manganese sulfate, 5 parts of potassium humate, and 18 parts of zinc sulfate.

[0044] Wherein, the preparation method of the modified attapulgite is to first soak the attapulgite with hydrochloric acid with a mass percentage concentration of 25% for 1 hour, let it stand, clarify, centrifuge, wash the solid with water until it is neutral, dry it, and then add 1 part of ethylenediaminetetraacetic acid and 1 part of silane coupling agent KH550, stir evenly, dry, grind into powder, and obtain.

[0045] Wherein, the water content of the sludge is 60%.

[0046] The preparation method of present embodiment humic acid compound fertilizer comprises the following steps:

[0047] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com