Preparation method of 2,3,3,3-tetrafluoropropylene

A technology of tetrafluoropropene and trifluoropropene, which is applied in the field of chemical synthesis, can solve the problems of low production of tetrafluoropropene and difficulty in catalyst preparation, and achieve the effects of good conversion rate, wide industrial application prospect and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

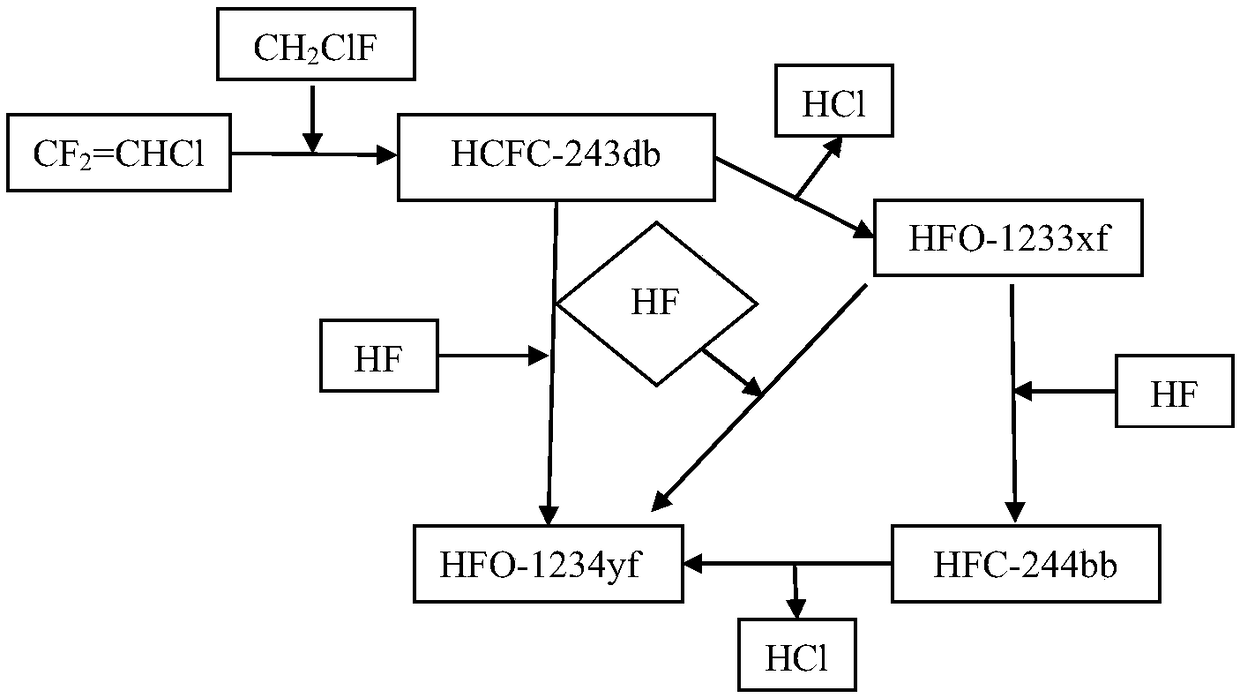

Method used

Image

Examples

Embodiment 1

[0028] To the Monel tube reactor Ⅰ with a length of 1.5m and an inner diameter of 100mm, the catalyst SbF 3 -SbF 5 -AlCl 3 / C, the temperature of reactor I is set to 220°C, and the pressure is set to 4bar; the CH 2 ClF and CF 2 = CHCl is mixed at a molar ratio of 10:1 and passed into the reactor Ⅰ, and the residence time is controlled to be 10s. The reaction product is cooled by circulating water at 20°C to recover the liquid product, and the gas product is recycled to the reactor Ⅰ.

[0029] The HCFC-243db is sent to the preheater through the metering pump, then enters the vaporization mixer, and then enters the CrF 3 The catalyst is placed in the Reactor II of a Hastelloy corrosion-resistant nickel-based alloy tube with a length of 1 m and an inner diameter of 60 mm. Control the reaction temperature to 320° C., the reaction pressure to 5 bar, and the residence time to 60 s. The reaction product is washed with alkali and water at 40°C, and after drying, the gas product H...

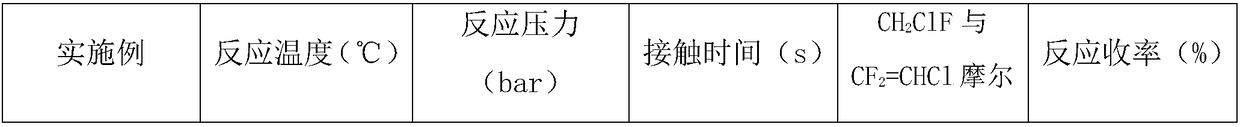

Embodiment 1-5

[0032] Add the catalyst SbF 3 -SbF 5 -AlCl 3 / C, where Sb 3+ , Sb 5+ 、Al 3+ The molar ratio is 1:1:1, and 2-chloro-1,1-difluoroethylene (CF 2 =CHCl) and chlorofluoromethane (CH 2 ClF), the product should be made into HCFC-243db after alkali washing, water washing and rectification. The reaction conditions and reaction results are shown in Table 1.

[0033] Table 1: Preparation of HCFC-243db.

[0034]

[0035]

Embodiment 6-10

[0037] After the HCFC-243db made in Examples 1-5 is transported to the preheater by a metering pump, it is passed into the monel tube reactor II with a length of 1.5m and an inner diameter of 100mm, and the reactor II is filled with catalyst Cr 2 o 3 - Ni / C, wherein the mass ratio of Cr to Ni is 2:1. Anhydrous HF gas was introduced into the reactor II, and the reaction product was washed with alkali, washed with water, and rectified to obtain HFO-1234yf. The reaction conditions and results are shown in Table 2.

[0038] Table 2: Preparation of HFO-1234yf by Step 2(a).

[0039]

[0040] The reaction total conversion rate in conjunction with embodiment 1 and embodiment 6 is 32.7%, the reaction total conversion rate in conjunction with embodiment 2 and embodiment 7 is 41.2%, the reaction total conversion rate in conjunction with embodiment 3 and embodiment 8 is 49.5% , The total reaction conversion rate combined with Example 4 and Example 9 was 52.2%, and the total reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com