Method for preparing magnesium borate whisker ceramic film supporter with proper porosity and compressive strength

A technology of ceramic membrane support and magnesium borate whiskers, which is applied in the field of preparation of in-situ synthesis of magnesium borate whiskers porous ceramics by solid-state sintering method, can solve the problems of large range of compressive strength and porosity, magnesium borate whiskers Problems such as complex porous ceramic process, to achieve the effect of easy operation, energy saving and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

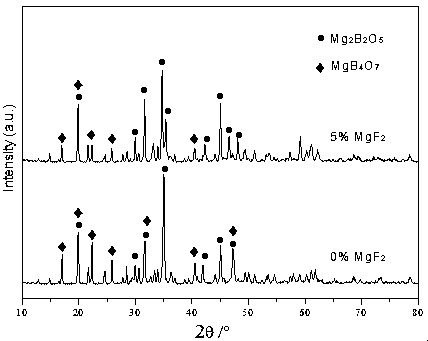

[0050] A method for preparing a magnesium borate whisker ceramic membrane support with suitable porosity and compressive strength. The method uses basic magnesium carbonate and boric acid as main raw materials, magnesium fluoride as a sintering aid, and polyvinyl alcohol binder, etc. , through the process of weighing, ball milling, pressing, drying and sintering, the magnesium borate whisker porous ceramic whose skeleton is composed of magnesium borate whiskers was directly synthesized in situ. The specific steps are as follows:

[0051] Step 1, the basic magnesium carbonate and boric acid are mixed according to the Mg:B molar ratio of 1:1.1 to 1:1.5, and the mass content is magnesium fluoride and magnesium fluoride with a mass content of 1% to 5% of the total mass of basic magnesium carbonate and boric acid. The polyvinyl alcohol with a content of 5% of the total mass of basic magnesium carbonate and boric acid, and the deionized water with a mass content of 55.56% of the tota...

Embodiment 1

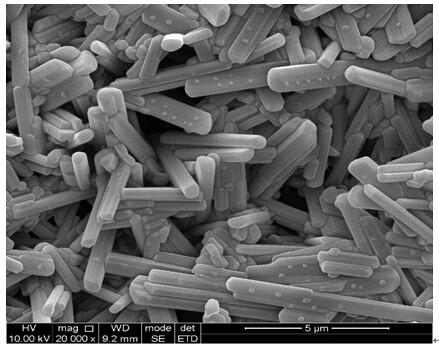

[0057] Take 8.1589g basic magnesium carbonate, 7.7906g boric acid, and 0.7975g polyvinyl alcohol and put them into a ball mill jar. Add 9ml of deionized water into the ball mill jar, and use wet ball milling. Place the ball mill pot in a planetary ball mill and mill it at a rate of 300r / min for 8 hours to obtain ceramic powder. Put the powder obtained after ball milling in an oven and dry at 80°C for 15 hours. Weigh the dried powder in the mold Medium compression molding, the diameter and thickness of the formed green body are both 22mm, the green body obtained after pressing is placed in an oven for 2 hours at 110°C, and then the dried body is placed in a quartz dry pot and then placed in a box-type high-temperature furnace In the process, the temperature was first raised from room temperature to 600°C at a rate of 2°C / min, and kept for 1 hour, then raised to 900°C at a rate of 5°C / min and held for 2 hours, and finally cooled to room temperature with the furnace. The cooled ...

Embodiment 2

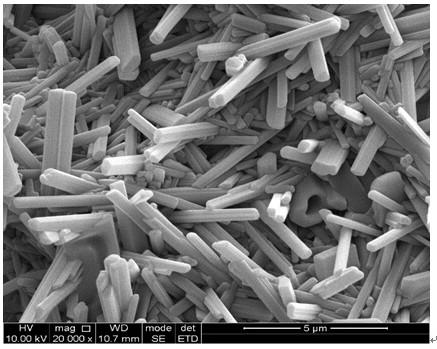

[0059] Take 8.1589g basic magnesium carbonate, 7.7906g boric acid, 0.1595g magnesium fluoride, and 0.7975g polyvinyl alcohol and put them into a ball mill jar. Add 9ml of deionized water into the ball mill jar, and use wet ball milling. Place the ball mill pot in a planetary ball mill and mill it at a rate of 300r / min for 8 hours to obtain ceramic powder. Put the powder obtained after ball milling in an oven and dry at 80°C for 15 hours. Weigh the dried powder in the mold Medium compression molding, the diameter and thickness of the formed green body are both 22mm, the green body obtained after pressing is placed in an oven for 2 hours at 110°C, and then the dried body is placed in a quartz dry pot and placed in a box-type high temperature In the furnace, first raise from room temperature to 600°C at a rate of 2°C / min, hold for 1 hour, then raise to 900°C at a rate of 5°C / min and hold for 2 hours, and finally cool down to room temperature with the furnace. The cooled sample w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com