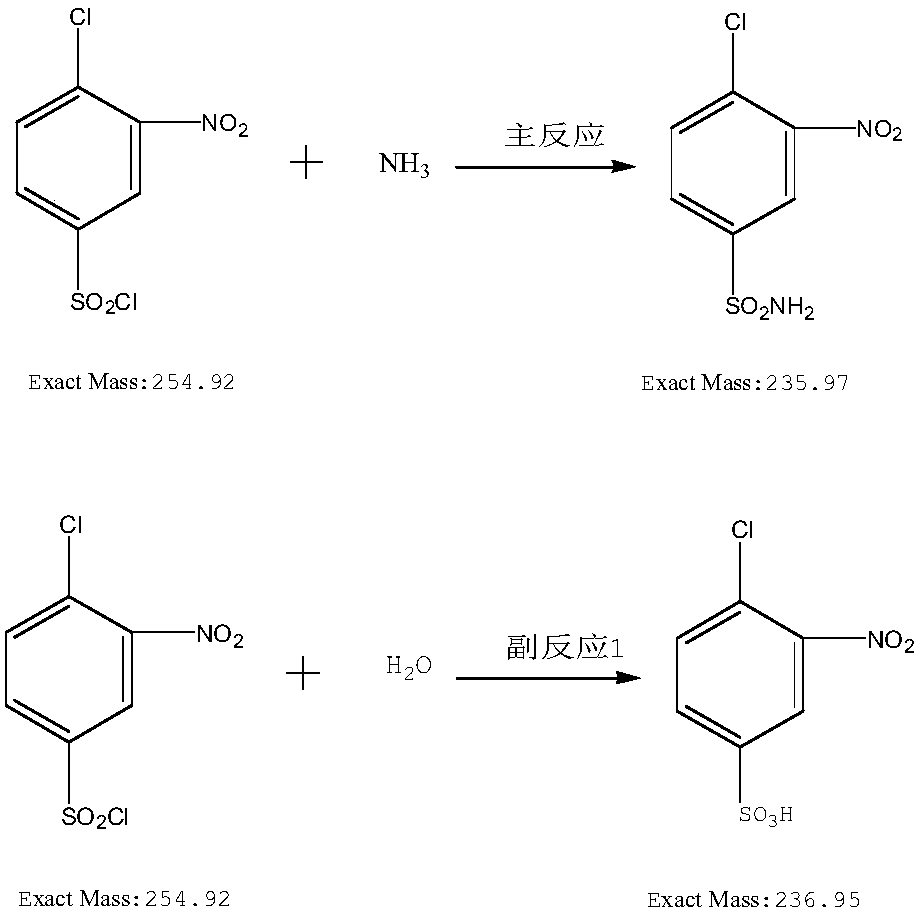

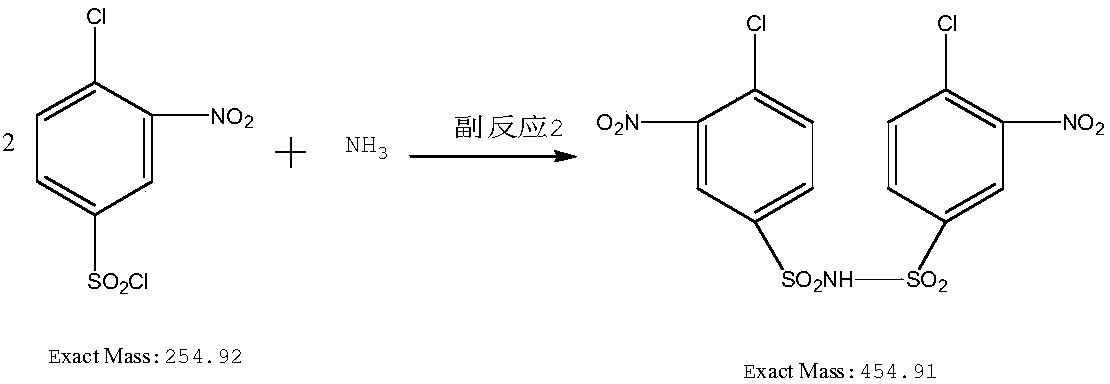

Preparation method of 2-nitrochlorobenzene-4-sulfamide

A technology of nitrochlorobenzene and sulfonamide, which is applied in the preparation of sulfonamide, organic chemistry, etc., can solve problems such as hazards to operators in the industrial production environment, reduced product yield, and reduced production capacity, so as to improve the production environment and reduce side effects. The production of products and the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add water 200g, 2-nitrochlorobenzene-4-sulfonyl chloride wet product 80g (mass fraction 61.2%) in a clean three-necked bottle, convert into 2-nitrochlorobenzene-4-sulfonyl chloride 49g, and Turkish red oil 1g As a wetting agent, stir and beat for 30 minutes, then add 40 g of solid ammonium chloride, stir for 15 minutes, add dropwise an aqueous sodium hydroxide solution with a mass fraction of 20%, and adjust the pH of the system to increase the pH of the feed solution to 7 -9, then heat up to 30-55°C and keep warm for the ammoniation reaction. In the reaction process, use a 20% sodium hydroxide aqueous solution to maintain the pH value of the ammoniation feed solution in the system between 7-9 until the ammoniation The end point of the reaction is complete, cool to make the product precipitate completely, filter, wash the filter cake twice with cold water, and dry the wet product at 95°C to obtain 42g of the ammoniated product 2-nitrochlorobenzene-4-sulfonamide, the yiel...

Embodiment 2

[0025] Add water 300g, 2-nitrochlorobenzene-4-sulfonyl chloride wet product 80g (mass fraction 61.2%) in a clean three-necked bottle, convert into 2-nitrochlorobenzene-4-sulfonyl chloride 49g, and Turkish red oil 0.5 g as a wetting agent, stirred and beaten for 30 minutes, then added solid ammonium chloride 64g, stirred for 30 minutes, added dropwise a mass fraction of 10% sodium hydroxide aqueous solution, and adjusted the pH value of the system so that the pH value of the feed liquid was raised to 7 or so, then, heat up to 60°C and keep warm for ammoniation reaction for 3 hours. In the reaction process, use a sodium hydroxide aqueous solution with a mass fraction of 15% to maintain the pH value of the ammoniation feed solution in the system between 7-8 until the ammoniation The end point of the reaction is complete, cool to make the product precipitate completely, filter, wash the filter cake twice with cold water, and dry the wet product at 90°C to obtain 38g of the ammoniat...

Embodiment 3

[0027] Add water 200g, 2-nitrochlorobenzene-4-sulfonyl chloride wet product 80g (mass fraction 61.2%) in a clean three-necked bottle, convert into 2-nitrochlorobenzene-4-sulfonyl chloride 49g, and Turkish red oil 1.5 g as a wetting agent, stirred and beaten for 40 minutes, then added 49 g of solid ammonium bicarbonate, stirred for 30 minutes, added dropwise a potassium hydroxide solution with a mass fraction of 15%, and adjusted the pH value of the system so that the pH value of the feed solution was raised to 8 Then, heat up to 40°C and keep warm for 3 hours for the ammoniation reaction. During the reaction, use a potassium hydroxide aqueous solution with a mass fraction of 15% to maintain the pH value of the ammoniation feed solution in the system between 7-9 until the ammoniation reaction The end point is complete, cool to make the product precipitate completely, filter, wash the filter cake twice with cold water, and dry the wet product at 95°C to obtain 41g of the ammonifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com