Tower type fluidized bed photobioreactor

A photobioreactor, fluidized bed technology, applied in photobioreactor, gas production bioreactor, bioreactor/fermenter combination, etc., can solve the problem of low solubility, long residence time, water turbidity, color In order to reduce the difficulty of management, improve the level of automation, and reduce the cost of training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

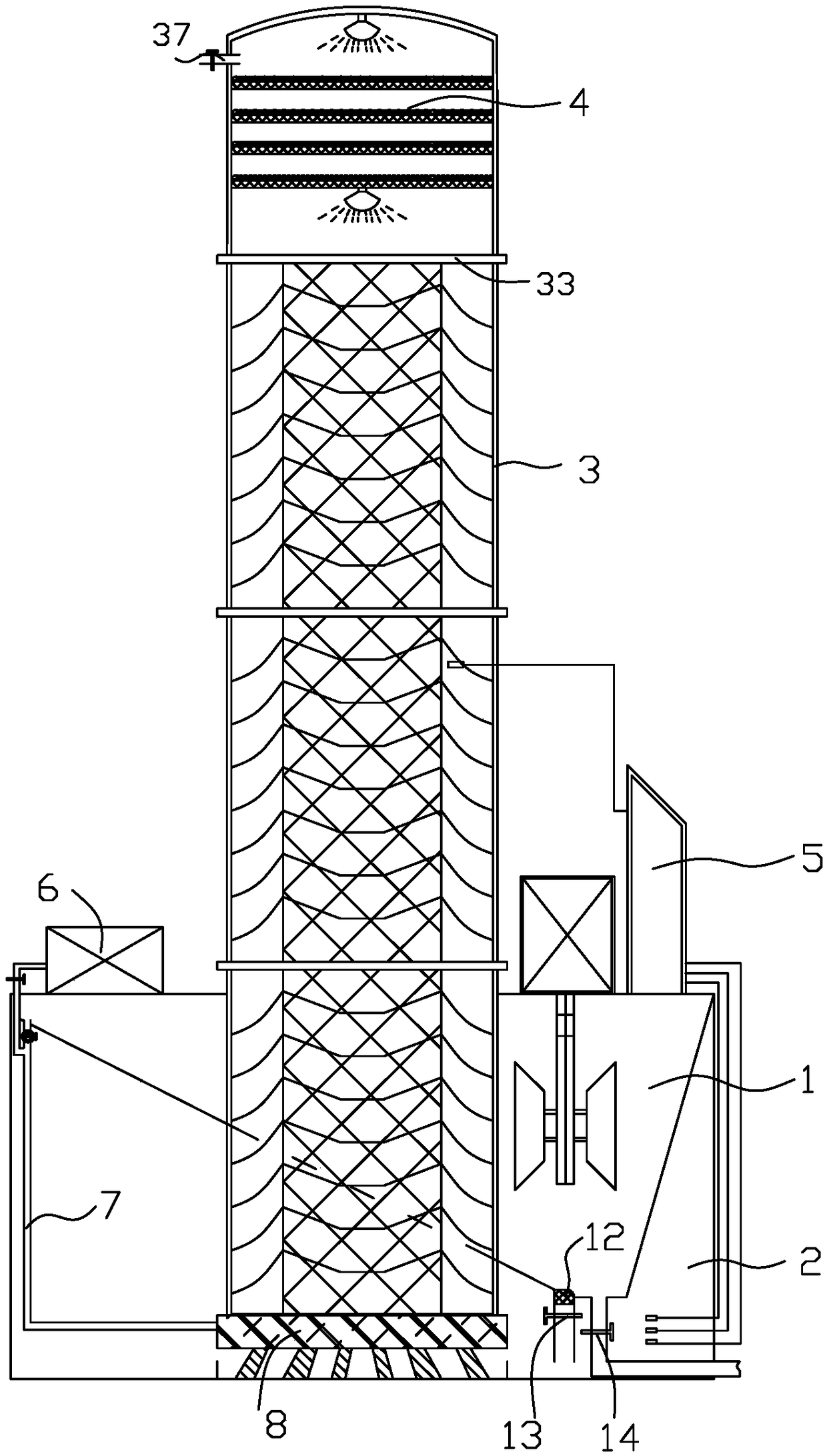

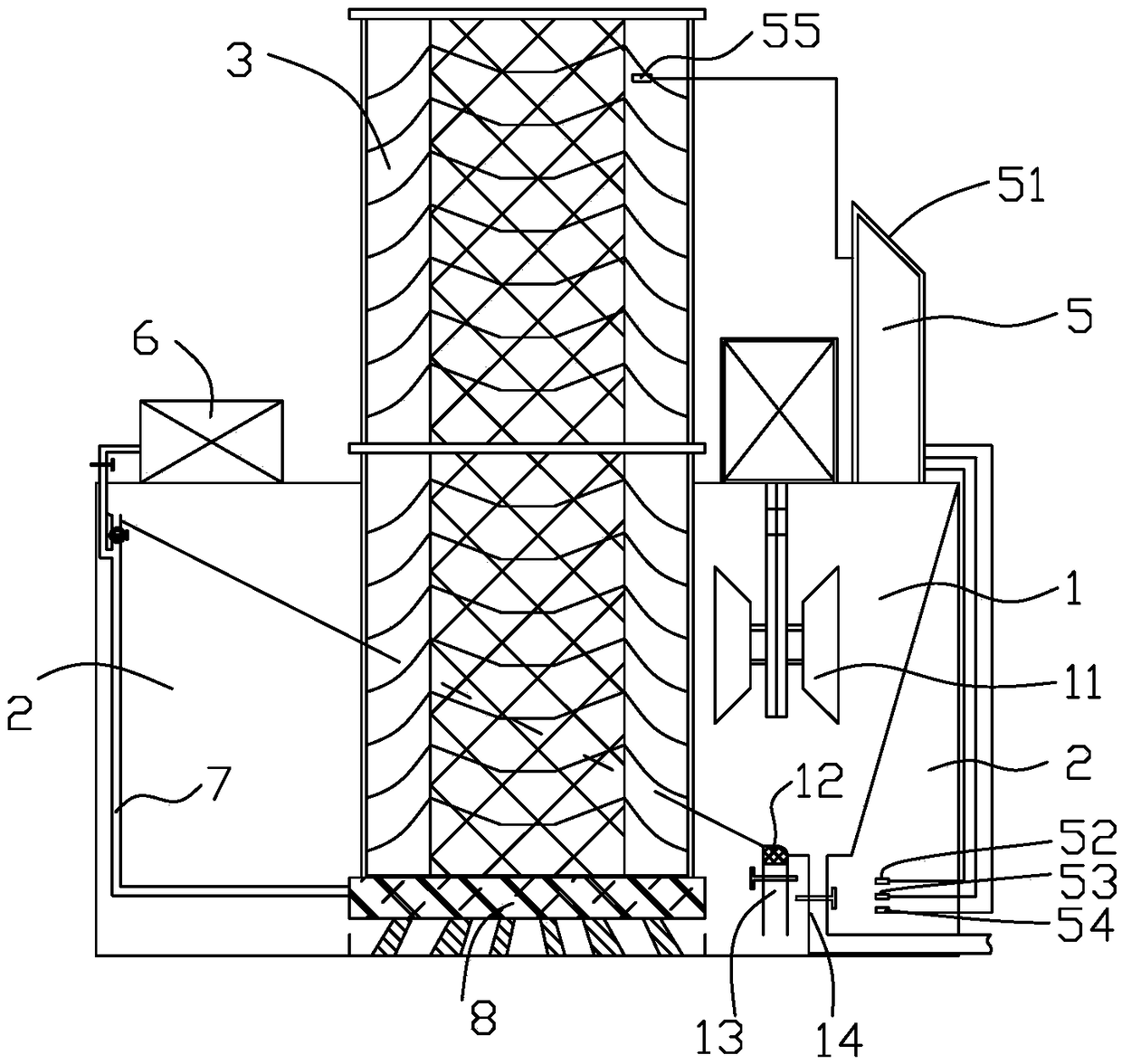

[0035] A tower type fluidized bed photobioreactor, comprising

[0036] The wastewater fermentation unit 1 is used to stir and ferment the wastewater collected in its internal cavity to obtain microalgae culture fluid;

[0037] The liquid collection unit 2 is connected to the waste water fermentation unit 1 to collect and store the microalgae culture solution;

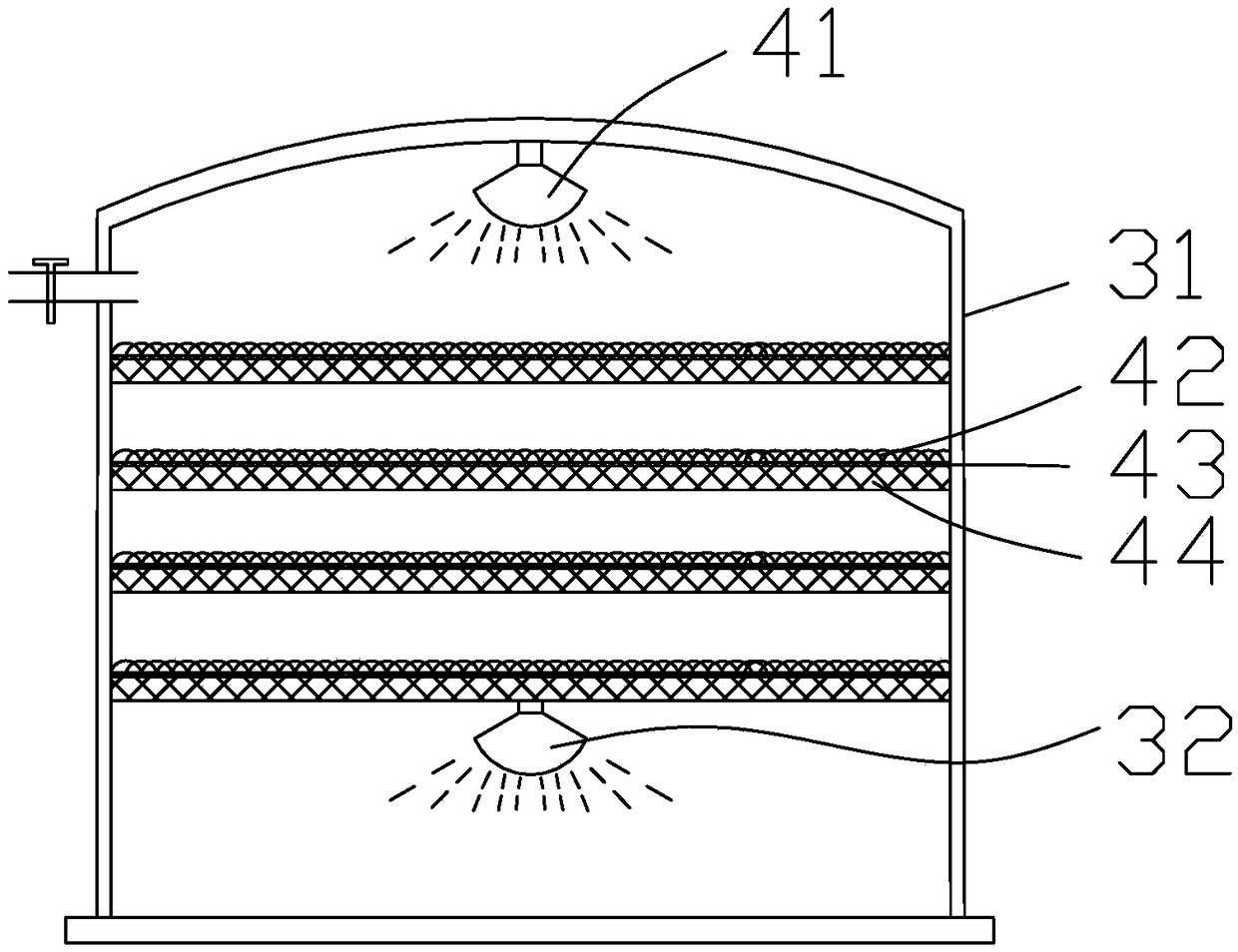

[0038] The cultivation treatment unit 3 is a tower structure, in which spray devices 32 and several layers of cultivation structures with holes are arranged in sequence from top to bottom, and immobilized activated sludge balls are arranged in the middle of the cultivation structure, and are located outside the cultivation structure. Immobilized algal bulbs are arranged on the upper part, and a waterproof light belt is also provided on the culture structure; the spray device 32 is connected to the liquid collection unit 2;

[0039] The adsorption sterilization unit 4 is located at the top of the cultivation treatment u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com