Device and method for improving output and quality of vinyl acetate produced by fluidized bed

A vinyl acetate, fluidized bed technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems affecting the production, quality, uneven gas distribution, poor fluidization state of vinyl acetate products, etc., To achieve the effect of reducing the blockage of the distribution plate holes in the fluidized bed reactor, reducing the impurity gas and reducing the impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation modes and specific operation processes, but the protection scope of the present invention is not limited to the following described embodiment.

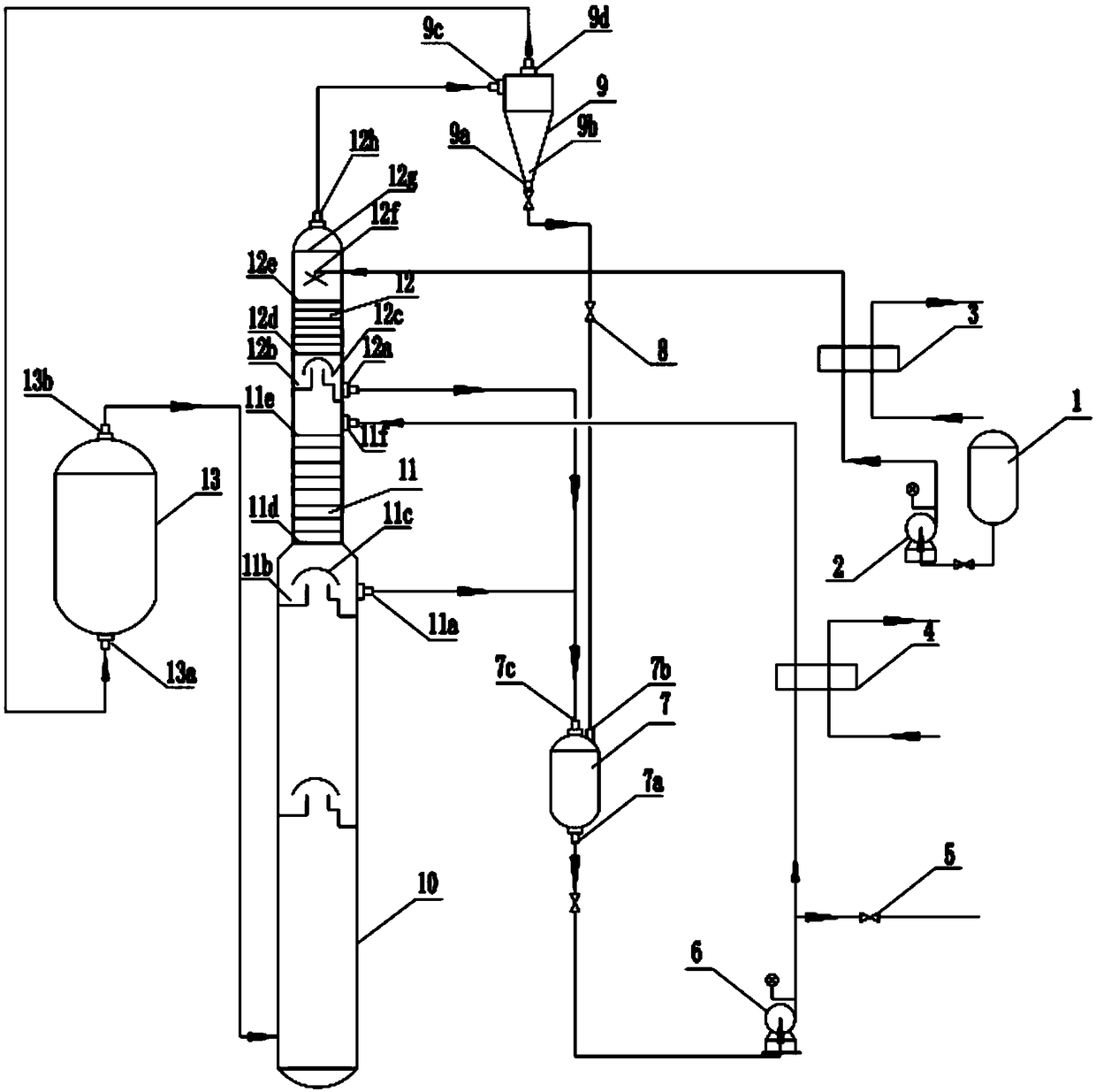

[0037] like figure 1 As shown, the present embodiment firstly sets the following device for improving the output and quality of vinyl acetate produced by fluidized bed: including acetic acid storage tank 1, the 1# pump 2, the acetic acid cooler 3, the reaction liquid cooler 4, the 1# regulating valve 5. The 2# pump 6, the reaction liquid buffer tank 7, the 2# regulating valve 8, the droplet separator 9, the three-stage gas separation tower 10 and the fluidized bed reactor 13;

[0038] The structure and function of the first section of the separation tower and the second secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com