Graphene supported SbVO4 nanoparticle composite material and preparation method thereof

A nanoparticle and composite material technology, applied in the field of electrochemistry, can solve problems such as restricting development and application, poor cycle performance, low specific capacity, etc., and achieve the effects of improving structural stability, mild reaction conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] (1) Preparation of electrode sheets

[0035] The end product that adopts embodiment to prepare gained is as active material, and acetylene black is as conductive additive, and sodium carboxymethylcellulose (CMC) is as binding agent, and the mass ratio of active material, acetylene black, CMC is 70:20:10; After they are fully mixed in proportion, a small amount of isopropanol is added, ground evenly, and evenly coated on copper foil; dried for 24 hours and cut into discs for later use.

[0036] (2) Assembly of Li-ion half-cells

[0037] With 1M LiPF 6 Dissolve in a mixed solution of ethylene carbonate (EC) and dimethyl carbonate (DMC) (the volume ratio of EC to DMC is 1:1) to obtain an electrolyte, the lithium sheet is the negative electrode, and the CR2032 stainless steel is assembled into a buckle for the battery case lithium-ion half-cell.

[0038] (3) Assembly of Na-ion half-cells

[0039] with 1M NaClO 4 Dissolve in a mixed solution of ethylene carbonate (EC) a...

Embodiment 1

[0042] A graphene-supported SbVO 4 A method for preparing a nanoparticle composite material, the steps of the method are as follows:

[0043] (1) 2mmol NH 4 VO3 Disperse the powder in 50mL deionized water, bath in 80℃ water until dissolved, and obtain a yellow transparent solution;

[0044] (2) 2mmol antimony trichloride hexahydrate (SbCl 3 ·6H 2 O) adding to the yellow transparent solution obtained in step (1), stirring and dispersing evenly to obtain a mixed dispersion;

[0045] (3) Add graphene oxide aqueous solution (the amount of graphene oxide is 52 mg) to the mixed dispersion obtained in step (2), stir and disperse evenly to obtain a suspension;

[0046] (4) Transfer the suspension obtained in step (3) to a 100mL polytetrafluoroethylene reactor, heat it in water at 180°C for 24h, and then cool it naturally to room temperature to obtain the crude product;

[0047] (5) The crude product obtained in step (4) was centrifugally washed twice with water and alcohol respec...

Embodiment 2

[0057] (1) 2mmol NH 4 VO 3 Disperse the powder in 50mL deionized water, bath in 80℃ water until dissolved, and obtain a yellow transparent solution;

[0058] (2) 1.8mmol antimony trichloride hexahydrate (SbCl 3 ·6H 2 O) adding to the yellow transparent solution obtained in step (1), stirring and dispersing evenly to obtain a mixed dispersion;

[0059] (3) Add graphene oxide aqueous solution (the amount of graphene oxide is 30mg) to the mixed dispersion liquid that step (2) obtains, stir and disperse evenly, obtain suspension;

[0060] (4) Transfer the suspension obtained in step (3) to a 100mL polytetrafluoroethylene reactor, heat it in water at 180°C for 26h, and then cool it down to room temperature naturally to obtain a crude product;

[0061] (5) Wash the product obtained in step (4) twice with water and alcohol, and dry at 80°C to obtain a graphene-supported SbVO 4 Nanoparticle composites.

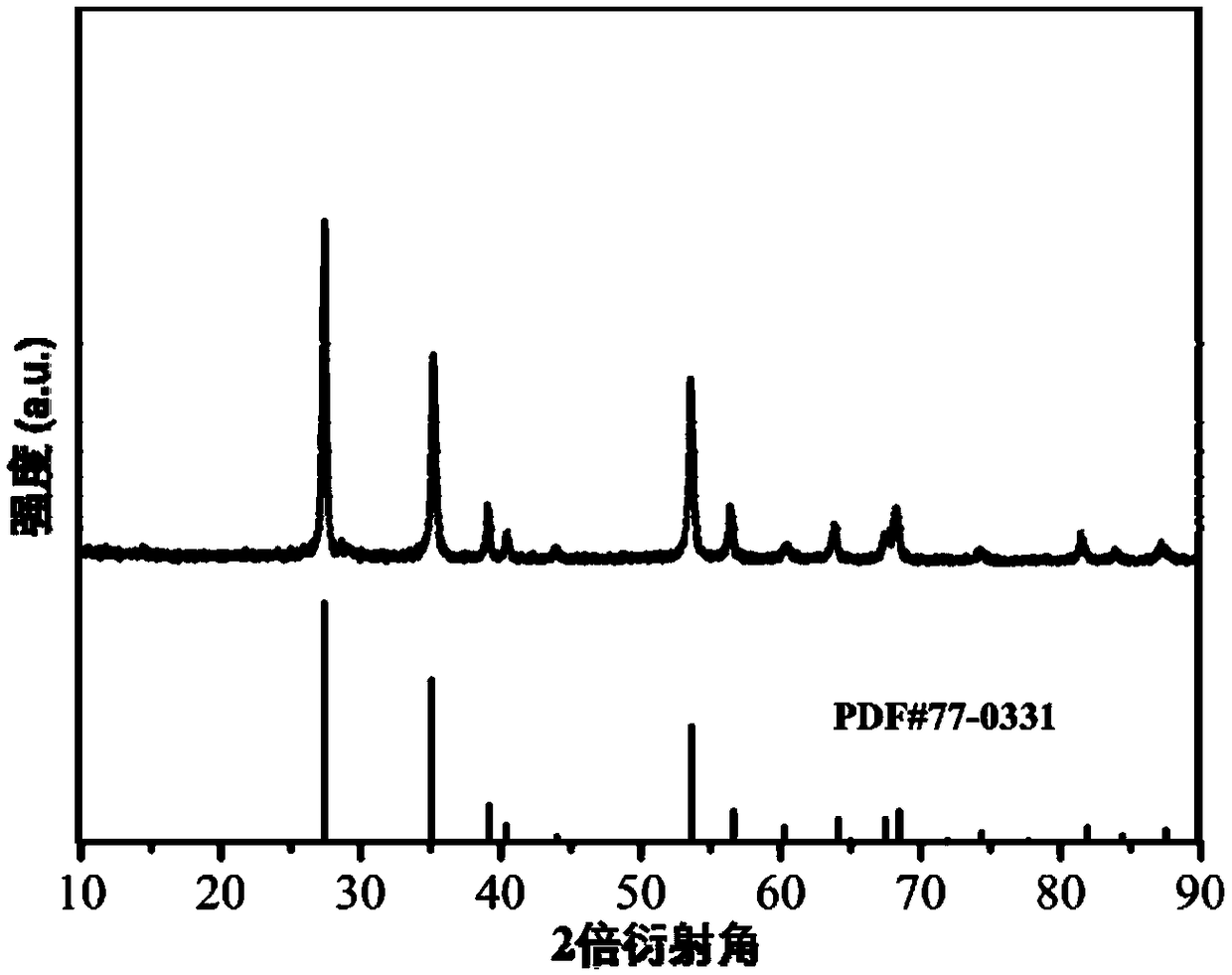

[0062] The XRD result of final product shows, described composite material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com