Method for machining hoop by using hoop drilling and tapping special machining equipment

A technology of processing equipment and processing methods, applied in the direction of metal processing equipment, other manufacturing equipment/tools, metal processing machinery parts, etc. Automate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

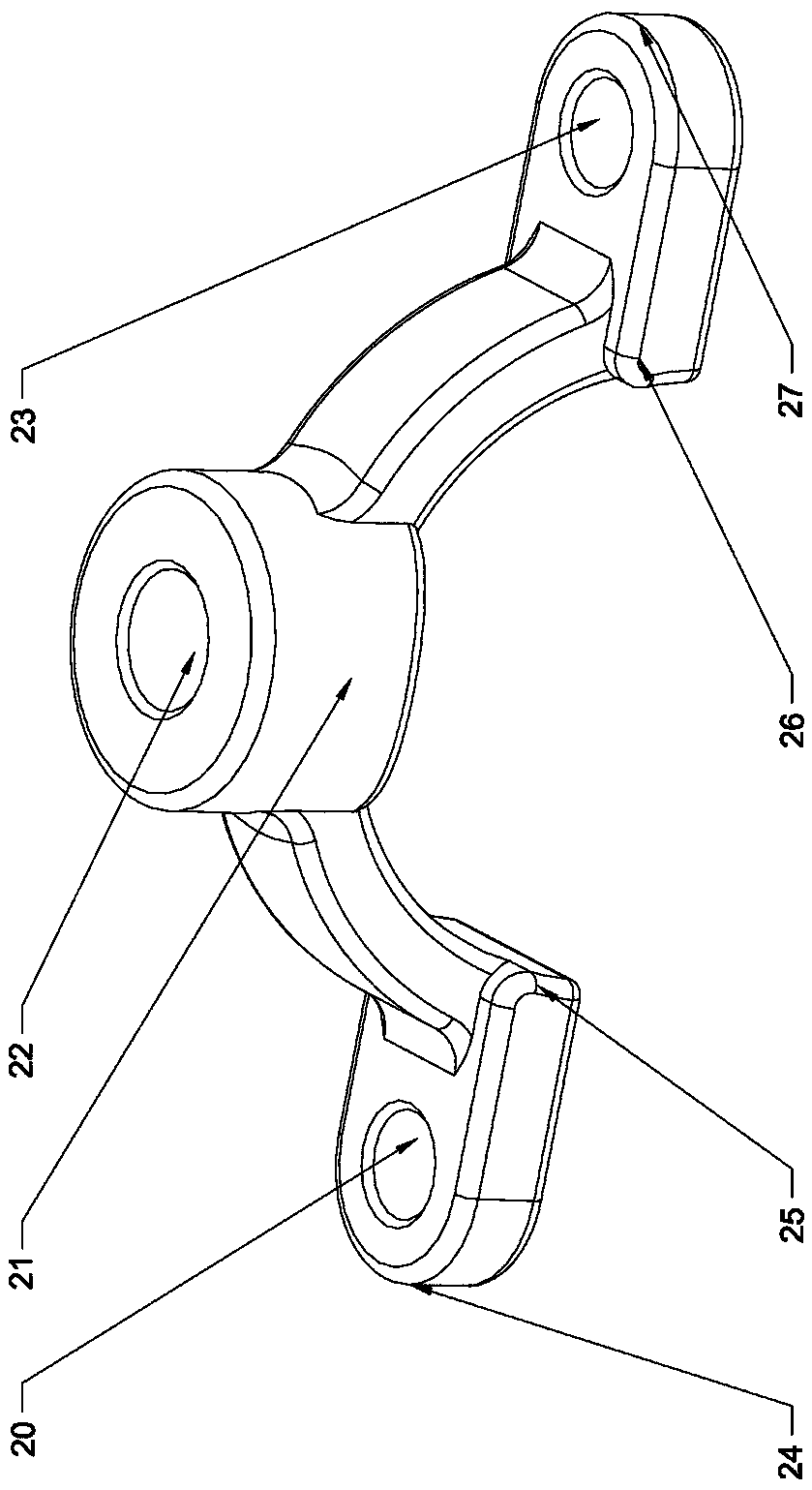

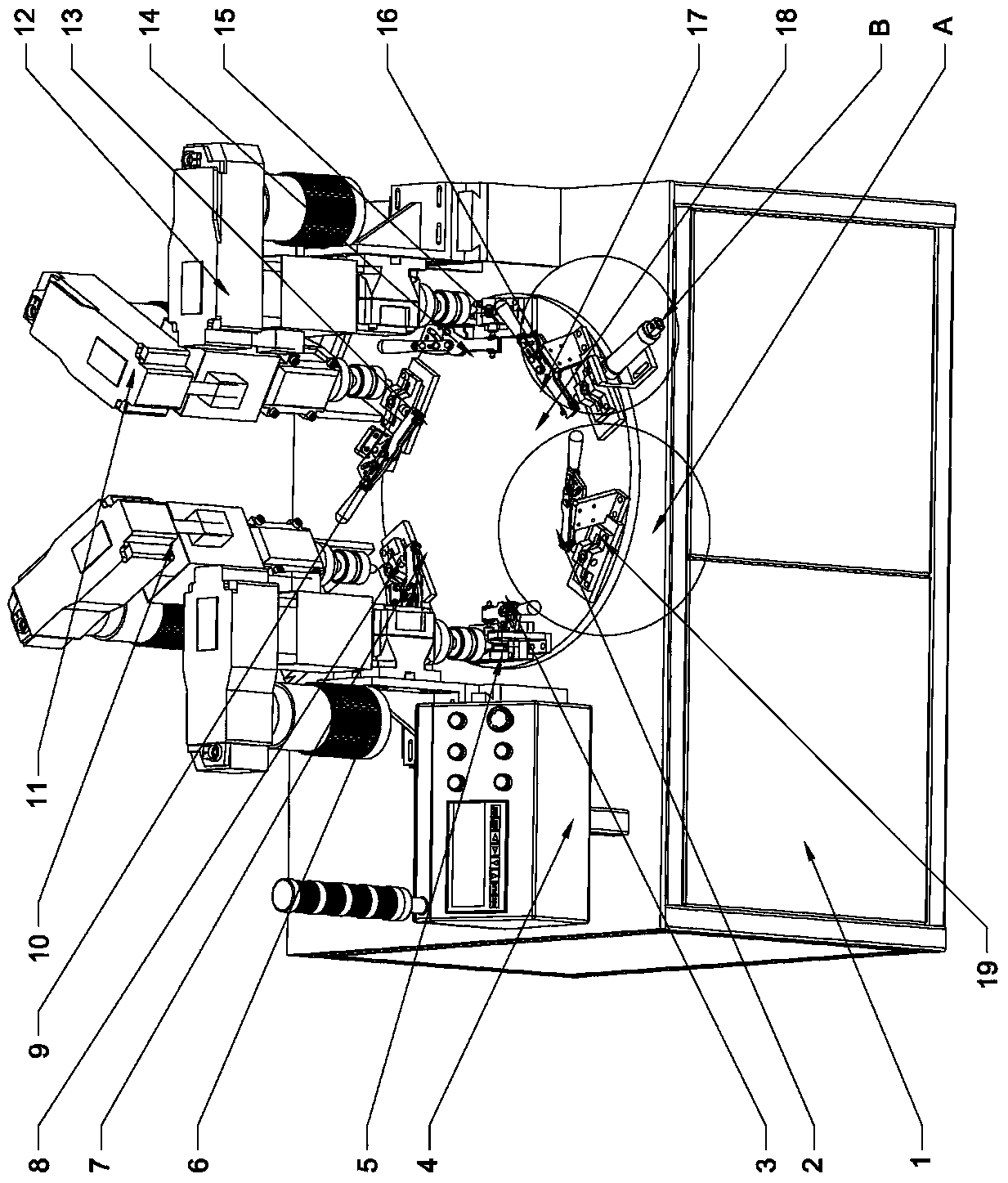

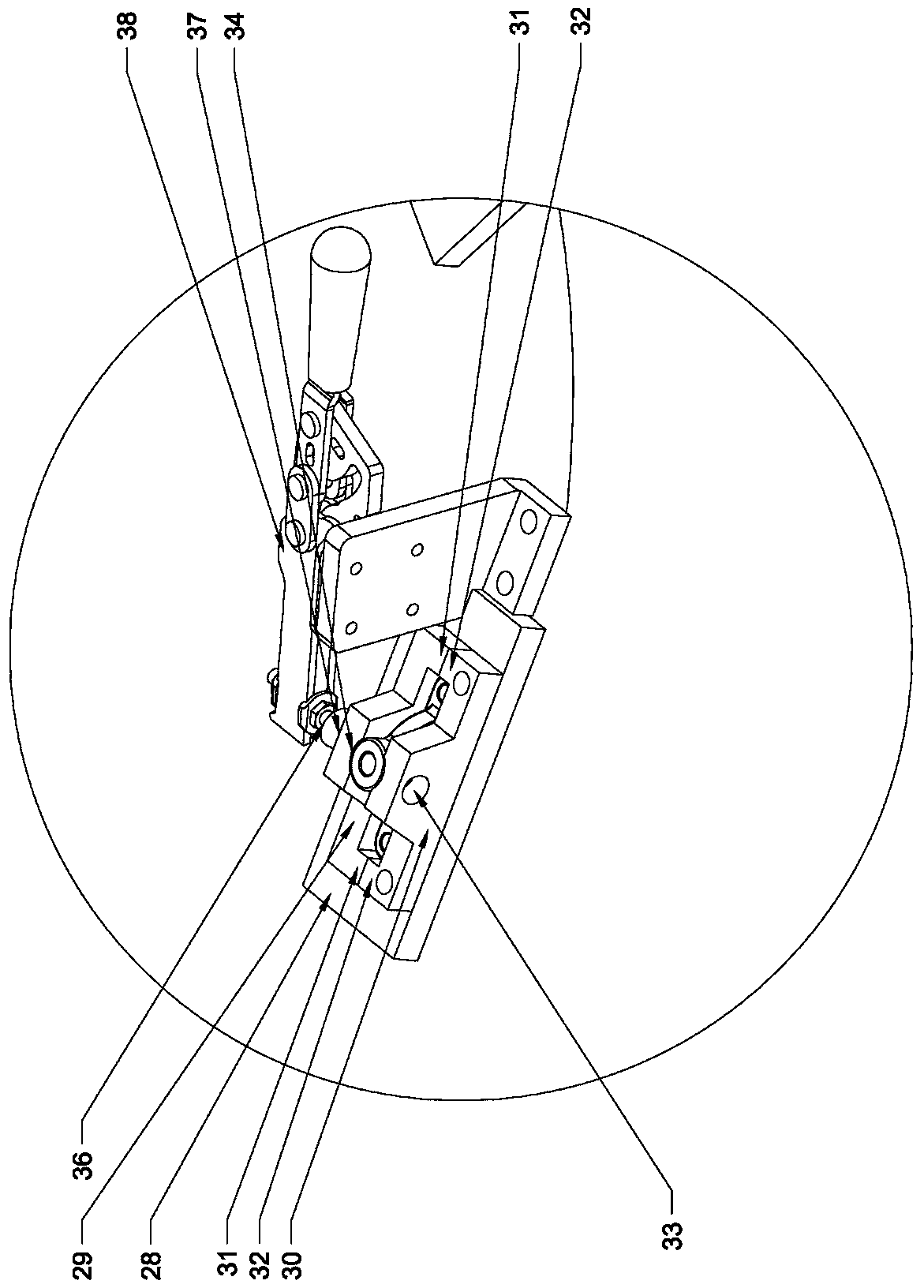

[0031] Such as Figure 1-6 As shown, a processing method for processing the hoop 21 by using special processing equipment for drilling and tapping the hoop 21, including a control base 1, an electric console 4 arranged on the control base 1, and a processing machine next to the electric console 4 Components, the rotating disk 18 arranged on the control base 1, the rotating drive assembly for driving the rotating disk 18, and the manual clamping station 19 and the 60° position 3 which are arranged on the rotating disk in turn. Side hole clamping station 5, center hole processing clamping station 10 at 120° position 7, No. 2 side hole clamping station 9 at 180° position 13, center hole tapping clamping station at 240° position 14 15 and its 300° position 17 reserved pick-up detection clamping station 16, No. 1 side hole processing station 6 set up with the No. 1 side hole clamping station 5, and center hole processing clamping station 8 set up The center hole processing station...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com