A high-efficiency anti-tumor potassium sodium niobate-based piezoelectric material and its preparation method and application

A potassium sodium niobate-based, piezoelectric material technology, applied in the field of piezoelectric ceramics, can solve the problems of residual tumor cells at the edge, inconvenient to carry external electrical appliances, damage to healthy tissues and other side effects, and achieve a lead-free and pollution-free biological phase. Capacitive, improve piezoelectricity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

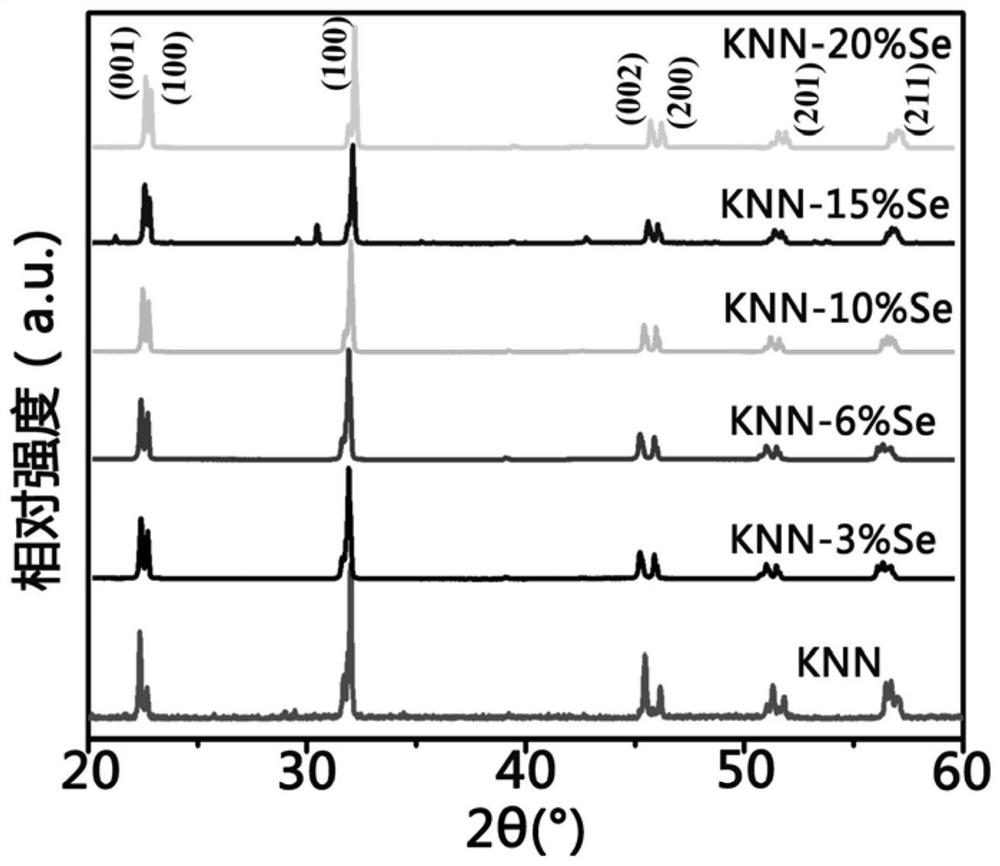

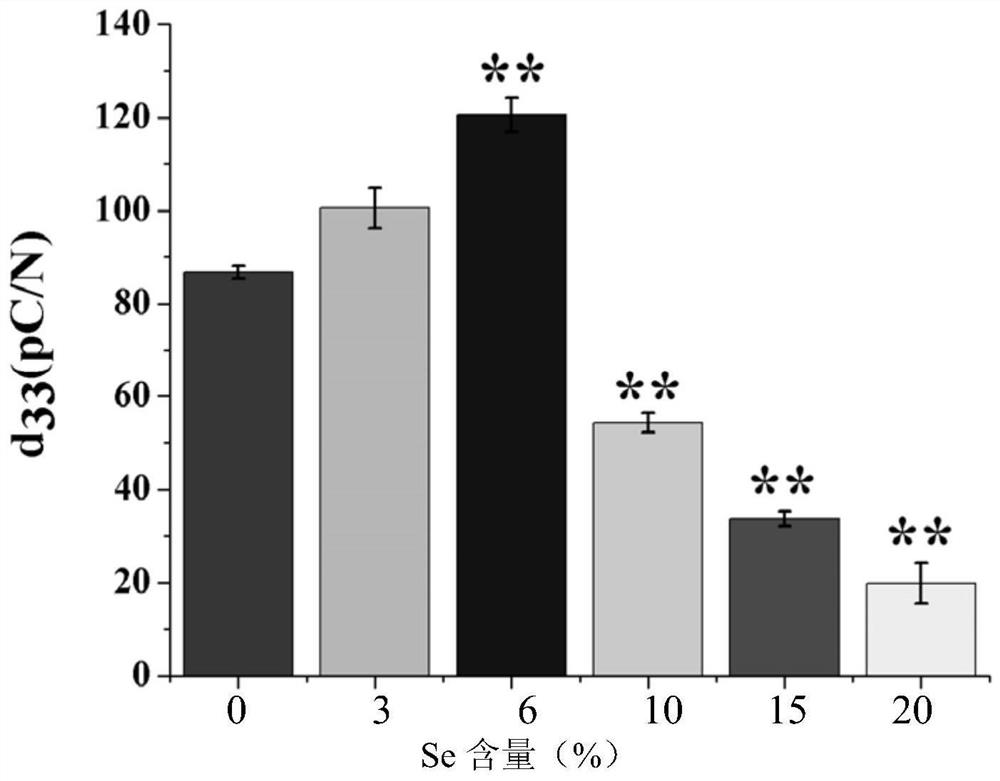

[0041] A preparation method of sodium selenite-doped potassium sodium niobate anti-tumor piezoelectric ceramic implant, comprising the following steps:

[0042] (1) Put absolute ethanol, niobium pentoxide, potassium carbonate, sodium carbonate and sodium selenite in a ball milling device for 8 hours at a speed of 300 rpm, let stand for 1 hour, dry at 60°C to constant weight, and calcinate at 750°C for 2 hours , be ground into powder, obtain sodium selenite doped potassium sodium niobate ceramic powder; Niobium pentoxide, potassium carbonate, sodium carbonate mass ratio 4:1:0.8; The consumption of sodium selenite is niobium pentoxide, 3% of the total mass of sodium carbonate and potassium carbonate; the ratio of the consumption of absolute ethanol to the total mass of niobium pentoxide, potassium carbonate, sodium carbonate and sodium selenite is 5mL:1g;

[0043](2) Sodium selenite doped potassium sodium niobate ceramic powder is ground, cross 80 mesh sieves, then with binding ...

Embodiment 2

[0047] A preparation method of sodium selenite-doped potassium sodium niobate anti-tumor piezoelectric ceramic implant, comprising the following steps:

[0048] (1) Put absolute ethanol, niobium pentoxide, potassium carbonate, sodium carbonate and sodium selenite in a ball milling device for 8 hours at a speed of 300 rpm, let stand for 1 hour, dry at 60°C to constant weight, and calcinate at 750°C for 2 hours , be ground into powder, obtain sodium selenite doped potassium sodium niobate ceramic powder; Niobium pentoxide, potassium carbonate, sodium carbonate mass ratio 4:1:0.8; The consumption of sodium selenite is niobium pentoxide, 6% of the total mass of sodium carbonate and potassium carbonate; the ratio of the consumption of absolute ethanol to the total mass of niobium pentoxide, potassium carbonate, sodium carbonate and sodium selenite is 5mL:1g;

[0049] (2) Sodium selenite doped potassium sodium niobate ceramic powder is ground, cross 80 mesh sieves, then with binding...

Embodiment 3

[0053] A preparation method of sodium selenite-doped potassium sodium niobate anti-tumor piezoelectric ceramic implant, comprising the following steps:

[0054] (1) Put absolute ethanol, niobium pentoxide, potassium carbonate, sodium carbonate and sodium selenite in a ball milling device for 8 hours at a speed of 300 rpm, let stand for 1 hour, dry at 60°C to constant weight, and calcinate at 750°C for 2 hours , be ground into powder, obtain sodium selenite doped potassium sodium niobate ceramic powder; Niobium pentoxide, potassium carbonate, sodium carbonate mass ratio 4:1:0.8; The consumption of sodium selenite is niobium pentoxide, 10% of the total mass of sodium carbonate and potassium carbonate; the ratio of the consumption of absolute ethanol to the total mass of niobium pentoxide, potassium carbonate, sodium carbonate and sodium selenite is 5mL:1g;

[0055] (2) Sodium selenite doped potassium sodium niobate ceramic powder is ground, cross 80 mesh sieves, then with bindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com