PEEK-modified (polyether-ether-ketone-modified) polyurethane infrared and ultraviolet fully shielding waterborne transparent thermal insulating paint

A heat-insulating coating and polyurethane technology, applied in polyurea/polyurethane coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., can solve problems such as poor dirt adhesion, unsatisfactory corrosion resistance, and short coating life. Excellent adhesion, remarkable effect of heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

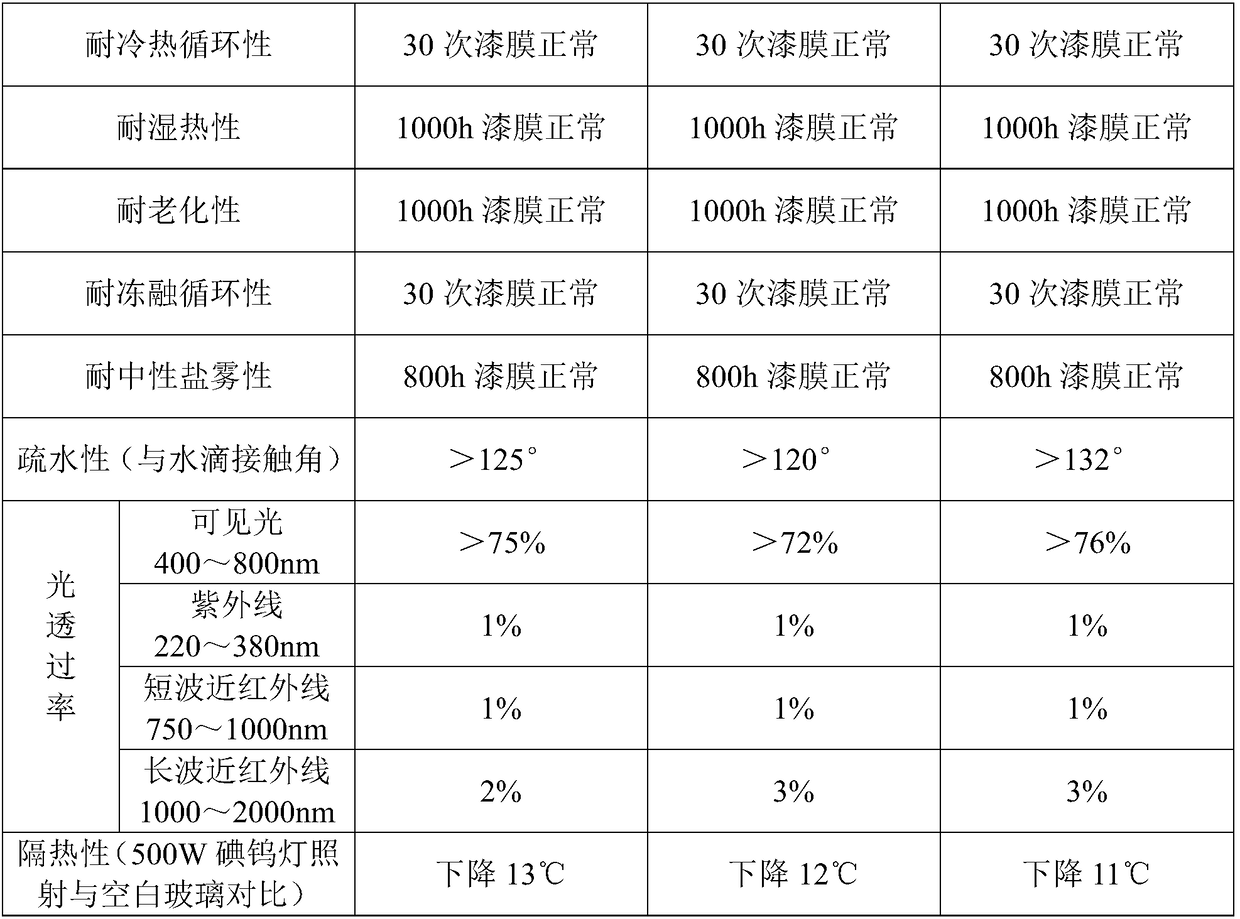

[0036] A PEEK modified polyurethane fully shielding infrared and ultraviolet water-based transparent heat-insulating coating, which consists of: 40.0 parts of PEEK modified water-based polyurethane resin A, 2.5 parts of dipropylene glycol methyl ether, 1.0 parts of silane coupling agent, 20% nano ATO dispersion 20.0 parts, 20% nano WO 3 Dispersion 10.0 parts, 20% nano LaB 6 Dispersion 5.0 parts, 10% nano TiO 2 8.0 parts of dispersion, 0.1 parts of leveling agent, 0.1 parts of defoamer, 0.3 parts of thickener, 0.2 parts of pH regulator, 12.8 parts of deionized water;

[0037] Wherein, the PEEK modified waterborne polyurethane resin A is described in Example 4 of the invention patent "A Polyetheretherketone Modified Polyurethane Waterborne Resin and Its Preparation Method".

Embodiment 2

[0039] A PEEK modified polyurethane fully shielding infrared and ultraviolet water-based transparent heat-insulating coating, which consists of: 45.0 parts of PEEK modified water-based polyurethane resin B, 2.5 parts of propylene glycol butyl ether, 1.0 parts of silane coupling agent, 25 parts by weight % Nano ITO dispersion 16.0 parts, 20% nano WO 3 Dispersion 15.0 parts, 10% nano CeO 2 5.0 parts of dispersion, 3.0 parts of 35% transparent iron oxide red paste, 0.1 parts of leveling agent, 0.1 parts of defoamer, 0.3 parts of thickener, 0.2 parts of pH regulator, 11.8 parts of deionized water;

[0040] Wherein, the PEEK modified waterborne polyurethane resin B is described in Example 5 of the invention patent "A Polyetheretherketone Modified Polyurethane Waterborne Resin and Its Preparation Method".

Embodiment 3

[0042] A PEEK modified polyurethane fully shielding infrared and ultraviolet water-based transparent heat-insulating coating, which is composed of: 50.0 parts of PEEK modified water-based polyurethane resin C, 3.0 parts of dipropylene glycol butyl ether, and 1.0 parts of silane coupling agent , 25% nano-IAO dispersion 12.0 parts, 25% nano-LaB 6 6.0 parts of dispersion, 25% nano WO 3 8.0 parts of dispersion, 6.0 parts of 15% nano-ZnO dispersion, 0.1 part of leveling agent, 0.1 part of defoamer, 0.2 part of thickener, 0.2 part of pH regulator, 13.4 parts of deionized water;

[0043] Wherein, the PEEK modified waterborne polyurethane resin C is described in Example 6 of the invention patent "A Polyetheretherketone Modified Polyurethane Waterborne Resin and Its Preparation Method".

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com